Acid Resistant Bricks

Product Description

Acid-resistant bricks are primarily made from quartz, feldspar, and clay, produced through high-temperature oxidation and decomposition. Their primary component is silicon dioxide, exceeding 70%. High-temperature firing produces a large amount of mullite, a highly acid-resistant material.

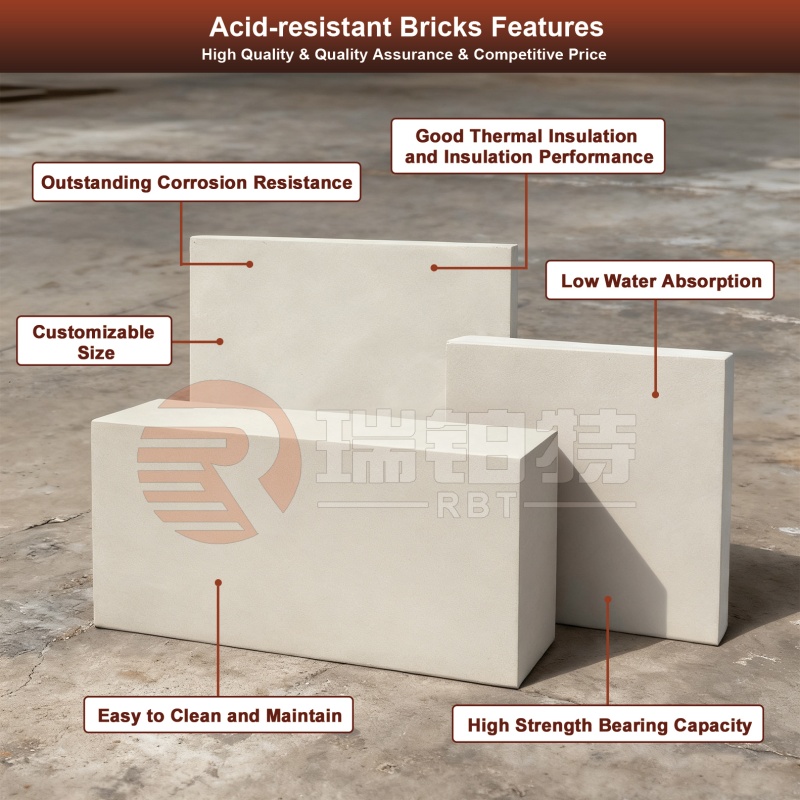

Feature:

Acid Resistance: With an acid resistance of 95% to 98%, they offer excellent corrosion resistance to most acids (except hydrofluoric and hot phosphoric acids), such as hydrochloric, sulfuric,

and nitric acids, as well as alkalis of varying concentrations at room temperature. However, they are not resistant to high-temperature molten alkalis.

Low Water Absorption: With a compact structure and a water absorption rate generally between 0.5% and 5.0%, they are not easily penetrated by solutions, maintaining excellent corrosion resistance and facilitating use in humid environments.

High Strength and Bearing Capacity: High-temperature firing results in high hardness and strength, excellent wear resistance, and the ability to withstand the pressure and friction of heavy objects. They are not easily damaged by external forces such as friction and impact.

Easy to Clean and Maintain: The smooth surface resists dirt accumulation, making cleaning easy without the use of chemicals. Installation is also simple, allowing for direct installation on substrates such as concrete and ceramic tiles, shortening the construction cycle.

Other Properties: It also offers excellent thermal insulation and electrical insulation properties. It is resistant to oxidation and contamination at room temperature, effectively preventing electrochemical and galvanic corrosion.

Frequently produced sizes:

230*113*15/20/30mm; 230*113*40/50/60mm; 150*75*15/20/30mm; 150*150*15/20/30mm; 200*200*15/20/30mm; 300*300*15/20/30mm

All sizes brick can be made single side groove or double sides groove, glaze or non-glaze.

Special size and OEM service are provided, too.

Non Glaze: anti-skidding, anti-exposure.

Glaze: Easy to clean, smooth and clear.

Product Index

|

Item |

Red |

Green |

|

Water Absorption, % |

5.5 |

0.20 |

|

Acid Resistance, % |

98.56 |

99.80 |

|

Pressure Resistance, Mpa |

79.9 |

80.0 |

|

Porosity, % |

12.6 |

|

|

Bulk Density, g/cm3 |

2.30 |

2.31-2.40 |

|

Bending strength, Mpa |

|

58.8 |

|

Al2O3, % |

20.24 |

|

|

SiO2, % |

65.79 |

|

|

Fe2O3, % |

6.93 |

Application

Acid-resistant bricks are mainly used in anti-corrosion projects in the chemical, metallurgical, electroplating, pharmaceutical, food and other industries. They can be laid on the ground, walls, tanks and other areas that come into contact with acidic media to resist acid corrosion and protect the substrate.

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.