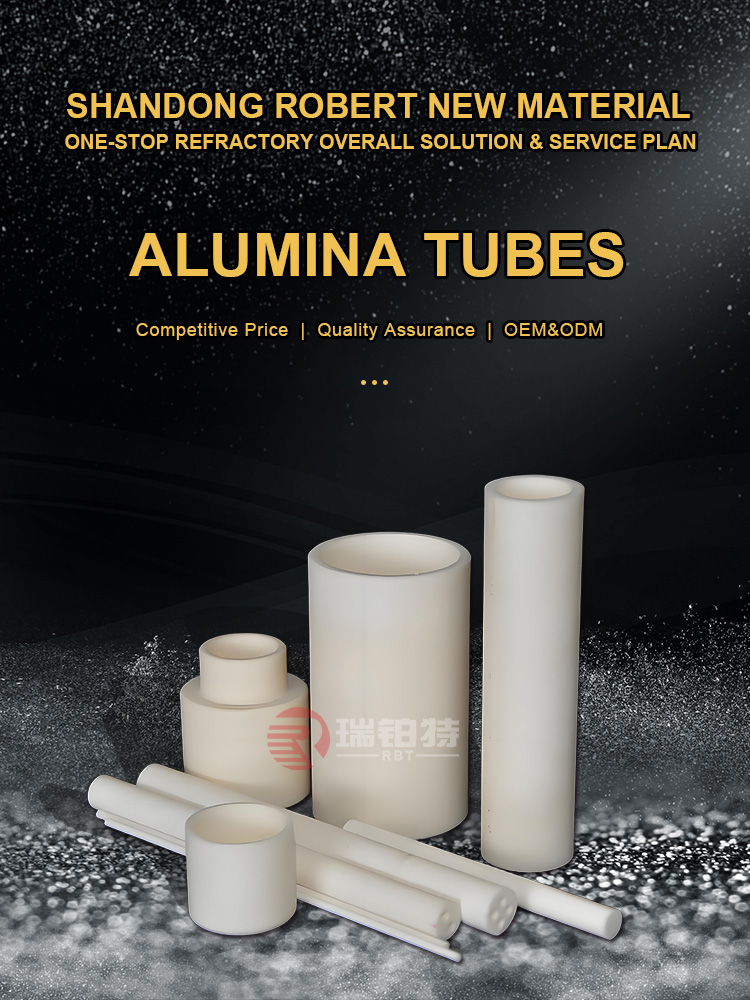

Alumina Ceramic Protection Tube

Product Information

Alumina tubes are mainly divided into corundum tubes, ceramic tubes and high aluminum tubes, which differ in composition, characteristics and applications.

Corundum tube: The raw material of corundum tube is alumina, and the main component is α-alumina (Al₂O₃). The hardness of corundum tube is large, the Rockwell hardness is HRA80-90, and the wear resistance is excellent, which is equivalent to 266 times that of manganese steel and 171.5 times that of high chromium cast iron. In addition, corundum tube has the characteristics of drop resistance, high density and good chemical stability. It is often used in wear-resistant parts, ceramic bearings, seals, etc. In addition, corundum tubes are also used for bearing materials of watches and precision machinery.

Ceramic tube: The composition of ceramic tube can be high-purity alumina (such as 99 porcelain) or ordinary alumina (such as 95 porcelain, 90 porcelain, etc.). High-purity alumina ceramics (such as 99 porcelain) have an Al₂O₃ content of more than 99.9%, and a sintering temperature of up to 1650-1990℃. They have excellent light transmittance and resistance to alkali metal corrosion. High-purity alumina ceramic tubes are often used in sodium lamps and integrated circuit substrates and high-frequency insulation materials in the electronics industry due to their superior light transmittance and corrosion resistance. Ordinary alumina ceramic tubes are used for high-temperature crucibles, refractory furnace tubes and special wear-resistant materials.

High-aluminum tube: The main component of high-aluminum tubes is alumina, but its content is usually between 48%-82%. High-aluminum tubes are known for their excellent high-temperature resistance and high strength. They are widely used in fields such as thermocouple protection tubes and tubular furnace casings. They can effectively protect internal components from high-temperature damage and extend their service life.

Details Images

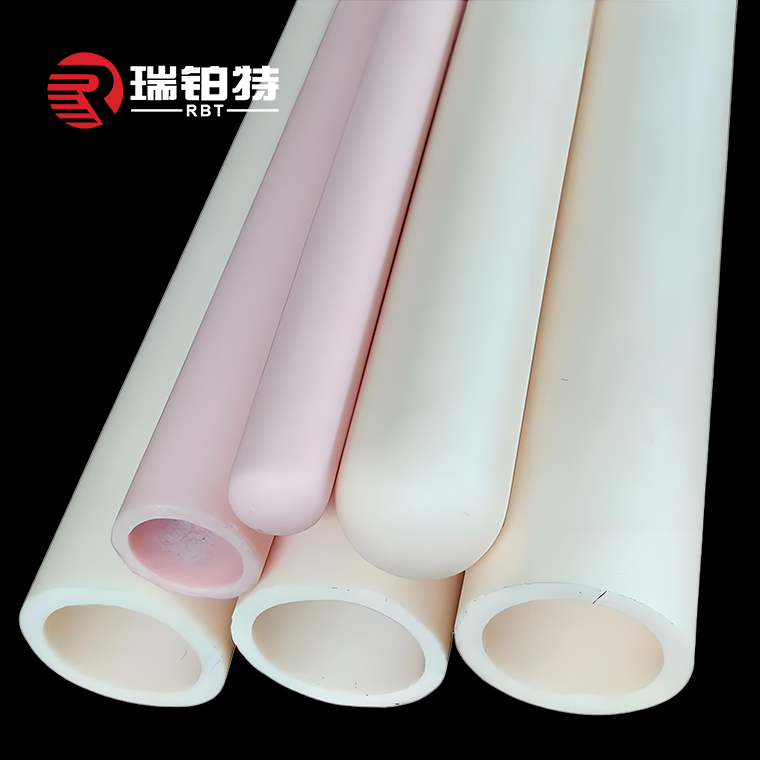

Alumina Ceramic Through Tubes

(Tubes with both ends open)

Alumina Ceramic Protection Tubes

(Tubes with one end open and one closed)

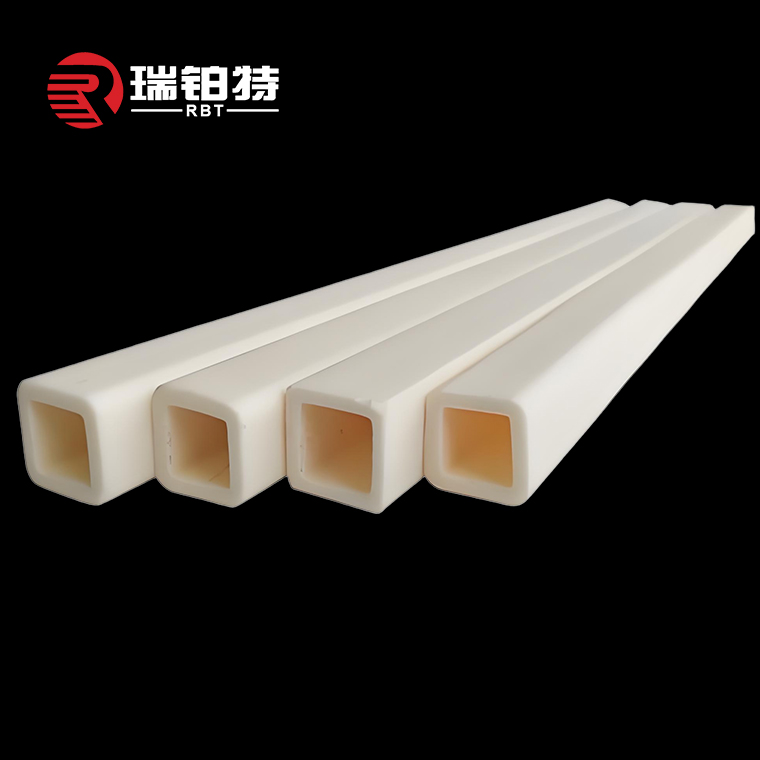

Alumina Ceramic Insulating Tubes

(Tubes with four pores)

Alumina Ceramic Insulating Tubes

(Tubes with two pores)

Ceramic Square Tube

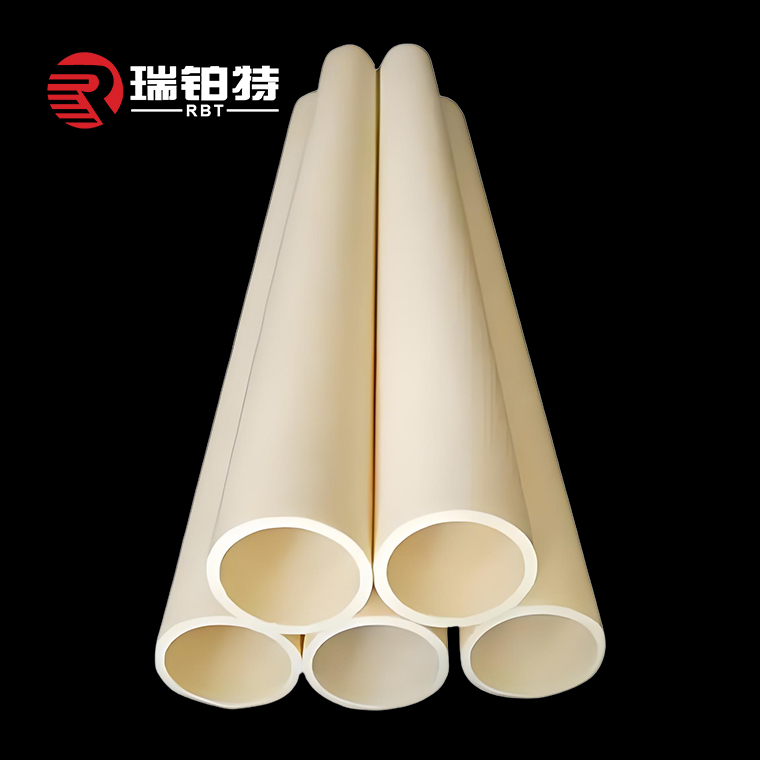

Large Diameter Ceramic Tube

Product Index

|

Index

|

Unit

|

85% Al2O3

|

95% Al2O3

|

99% Al2O3

|

99.5% Al2O3

|

|

|

Density

|

g/cm3

|

3.3

|

3.65

|

3.8

|

3.9

|

|

|

Water Absorption

|

%

|

<0.1

|

<0.1

|

0

|

0

|

|

|

Sintered Temperature

|

℃

|

1620

|

1650

|

1800

|

1800

|

|

|

Hardness

|

Mohs

|

7

|

9

|

9

|

9

|

|

|

Bending Strength(20℃))

|

Mpa

|

200

|

300

|

340

|

360

|

|

|

Compressive Strength

|

Kgf/cm2

|

10000

|

25000

|

30000

|

30000

|

|

|

Long Time Working Temperature

|

℃

|

1350

|

1400

|

1600

|

1650

|

|

|

Max. Working Temperature

|

℃

|

1450

|

1600

|

1800

|

1800

|

|

|

Volume Resistivity

|

20℃

|

Ω. cm3

|

>1013

|

>1013

|

>1013

|

>1013

|

|

100℃

|

1012-1013

|

1012-1013

|

1012-1013

|

1012-1013

|

||

|

300℃

|

>109

|

>1010

|

>1012

|

>1012

|

||

Specification&Common Sizes

|

Alumina Ceramic Through Tubes

|

|||||||||

|

Length(mm)

|

≤2500

|

||||||||

|

OD*ID(mm)

|

4*3

|

5*3.5

|

6*4

|

7*4.5

|

8*4

|

9*6.3

|

10*3.5

|

10*7

|

12*8

|

|

OD*ID(mm)

|

14*4.5

|

15*11

|

18*14

|

25*19

|

30*24

|

60*50

|

72*62

|

90*80

|

100*90

|

|

Alumina Content (%)

|

85/95/99/99.5/99.7

|

||||||||

|

Alumina Ceramic Protection Tubes

|

|||||||||

|

Length(mm)

|

≤2500

|

||||||||

|

OD*ID(mm)

|

5*3

|

6*3.5

|

6.4*3.96

|

6.6*4.6

|

7.9*4.8

|

8*5.5

|

9.6*6.5

|

10*3.5

|

10*7.5

|

|

OD*ID(mm)

|

14*10

|

15*11

|

16*12

|

17.5*13

|

18*14

|

19*14

|

20*10

|

22*15.5

|

25*19

|

|

Alumina Content(%)

|

95/99/99.5/99.7

|

||||||||

|

Alumina Ceramic Insulating Tubes

|

|||

|

Name

|

OD(mm)

|

ID(mm)

|

Length(mm)

|

|

One Pore

|

2-120

|

1-110

|

10-2000

|

|

Two Pores

|

1-10

|

0.4-2

|

10-2000

|

|

Four Pores

|

2-10

|

0.5-2

|

10-2000

|

Applications

Alumina Ceramic Through Tubes: Industrial Electric Heater; Laboratory Electric Furnace; Heat Treating Furnace.

Alumina Ceramic Protection Tubes: Temperature element protection; Thermocouple protection tube.

Alumina Ceramic InsulatingTubes: Mainly for the insulation between thermocouple wires.

Laboratory Electric Furnace

Heat Treating Furnace

Thermocouple Protection Tube

Mechanical Equipment

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.