Alumina Lining Bricks

Product Index

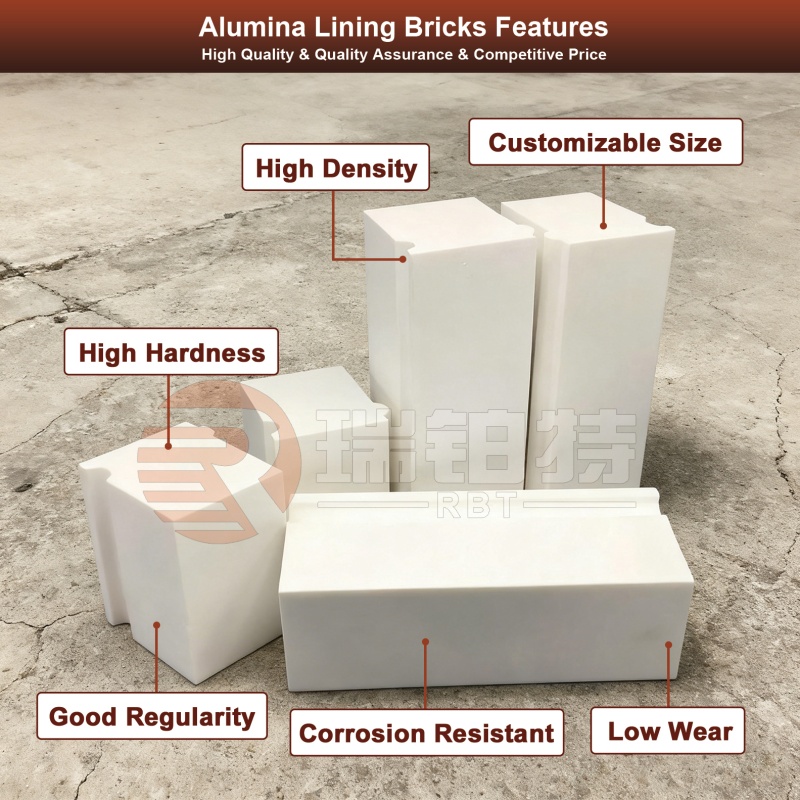

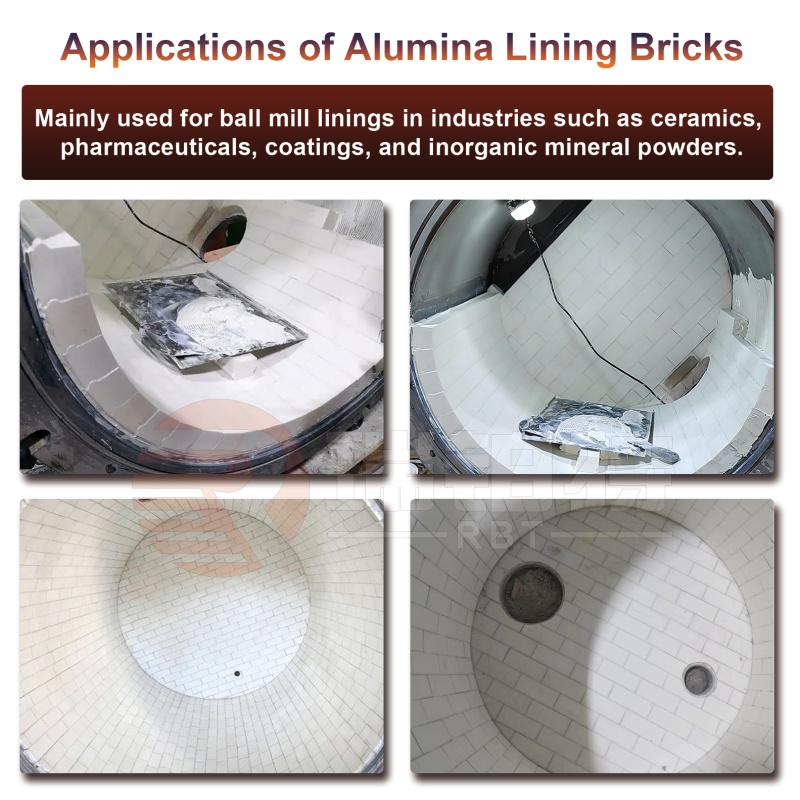

Wear-resistant alumina lining bricks are made from high-quality alumina powder with high purity, and can be used in the grinding of glazes and ceramic tiles. The product features high hardness, high density, low wear, good regularity, and corrosion resistance. Used as wear-resistant linings for ball mills, they are widely applied in industries such as ceramics, cement, oil, pigments, chemicals, pharmaceuticals, coatings, and inorganic mineral powders, effectively improving grinding efficiency, reducing grinding costs, and minimizing product contamination.

Product Index

|

Item

|

AM92

|

AM95

|

AME95

|

AM99

|

|

Al2O3(%)

|

92±0.5

|

95±0.5

|

95±0.5

|

99±0.5

|

|

Bending Strength(MPa)

|

≥220

|

≥250

|

≥300

|

≥330

|

|

Compressive Strength(MPa)

|

≥1050

|

≥1300

|

≥1600

|

≥1800

|

|

Fracture Toughness(MPam1/2)

|

≥3.7

|

≥3.8

|

≥4.0

|

≥4.1

|

|

Rockwell Hardness(HRA)

|

≥82

|

≥85

|

≥88

|

≥88

|

|

Loss Bulk(cm³)

|

≤0.5

|

≤0.2

|

≤0.3

|

≤0.11

|

|

Bulk Density (g/cm³)

|

3.6

|

3.65

|

3.7

|

3.88

|

Reference Dimensions

|

Lining Brick (Non Tapered)

|

||||||

|

H(mm)

|

35

|

40

|

50

|

60

|

70

|

90

|

|

W(mm)

|

50

|

50

|

50

|

50

|

50

|

50

|

|

L(mm)

|

150

|

150

|

150

|

150

|

150

|

150

|

|

Lining Brick (Tapered)

|

||||||

|

H(mm)

|

35

|

40

|

50

|

60

|

70

|

90

|

|

W(mm)

|

45/50

|

45/50

|

45/50

|

45/50

|

45/50

|

45/50

|

|

L(mm)

|

150

|

150

|

150

|

150

|

150

|

150

|

|

Lining Brick (Half-Non Tapered)

|

||||||

|

H(mm)

|

35

|

40

|

50

|

60

|

70

|

90

|

|

W(mm)

|

50

|

50

|

50

|

50

|

50

|

50

|

|

L(mm)

|

75

|

75

|

75

|

75

|

75

|

75

|

|

Lining Brick (Half-tapered)

|

||||||

|

H(mm)

|

35

|

40

|

50

|

60

|

70

|

90

|

|

W(mm)

|

45/50

|

45/50

|

45/50

|

45/50

|

45/50

|

45/50

|

|

L(mm)

|

75

|

75

|

75

|

75

|

75

|

75

|

|

Lining Brick (Thin-non Tapered)

|

||||||

|

H(mm)

|

35

|

40

|

50

|

60

|

70

|

90

|

|

W(mm)

|

25

|

25

|

25

|

25

|

25

|

25

|

|

L(mm)

|

150

|

150

|

150

|

150

|

150

|

150

|

|

Lining Brick (Thin Tapered)

|

||||||

|

H(mm)

|

35

|

40

|

50

|

60

|

70

|

90

|

|

W(mm)

|

22.5/25

|

22.5/25

|

22.5/25

|

22.5/25

|

22.5/25

|

22.5/25

|

|

L(mm)

|

150

|

150

|

150

|

150

|

150

|

150

|

Mining and Metallurgy: Ball mills, classifiers, chutes, and tapping troughs for metallurgical furnaces, resisting the abrasive wear of ore grinding and molten slag;

Building Materials: Cement/ceramic ball mills, cement kiln tertiary air ducts, glass melting furnace feed ports, etc., suitable for high-temperature grinding/material scouring scenarios;

Chemical and Pharmaceutical Industries: Reactors, slurry pipelines, and linings for pharmaceutical grinding equipment, resistant to acid and alkali corrosion and non-contaminating materials;

Power Industry: Coal mills in thermal power plants, fly ash conveying pipelines, and slag discharge pipes in waste-to-energy incinerators, resistant to wear from coal/slag;

Others: Wear-resistant parts for coating grinding equipment, coal chemical conveying pipelines, and environmental solid waste treatment equipment.

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.