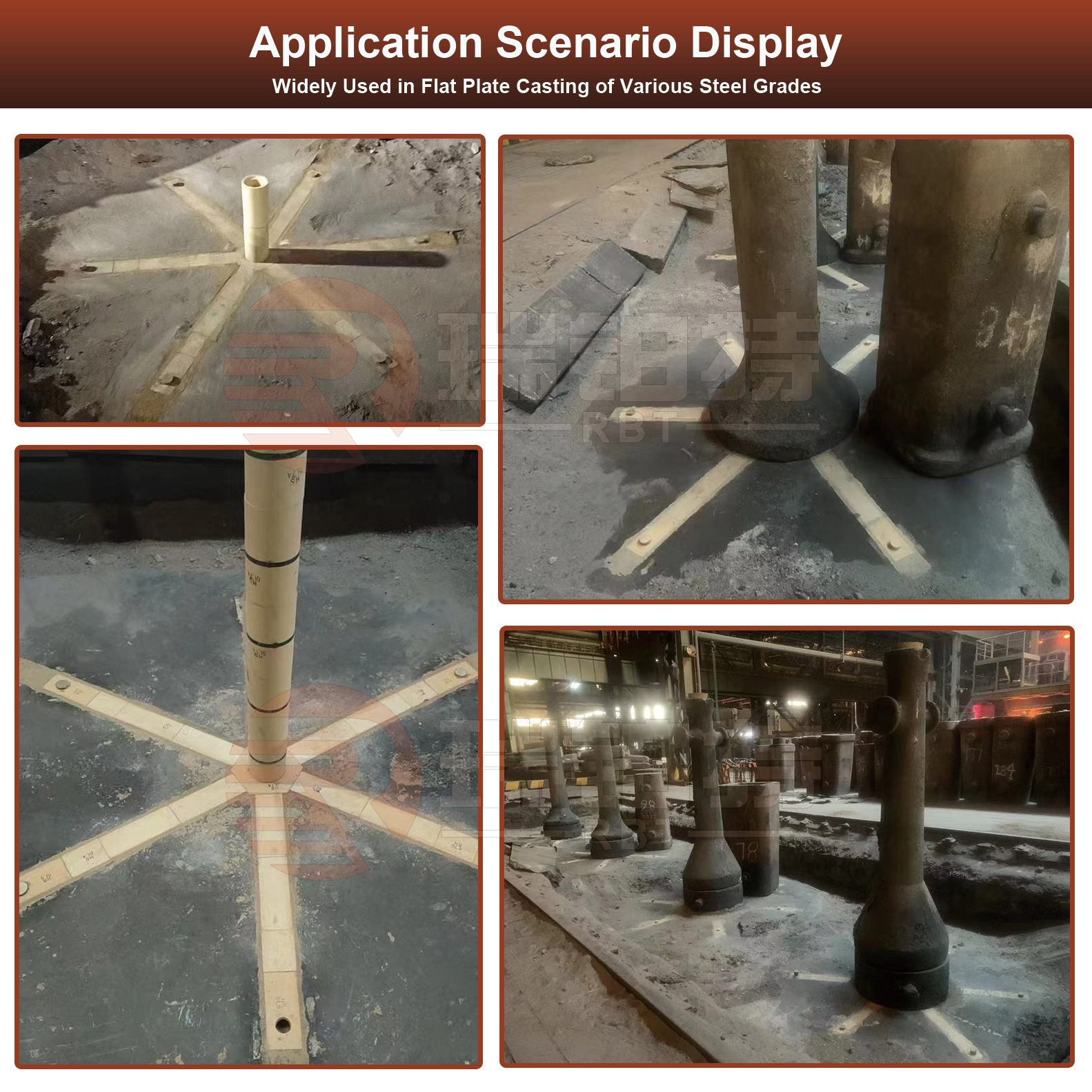

Free sample for Cast Irons Steel Foundry Industry Used High Alumina Bauxite/Mullite Spider Bottom Pouring Bricks

All we do is usually connected with our tenet " Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for Free sample for Cast Irons Steel Foundry Industry Used High Alumina Bauxite/Mullite Spider Bottom Pouring Bricks, Our company is working through the procedure principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a pleasant relationship with businessman from all around the earth.

All we do is usually connected with our tenet " Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for Refractory Brick and Brick Kiln, Why we can do these? Because: A, We're honest and reliable. Our items have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It might be highly appreciated.

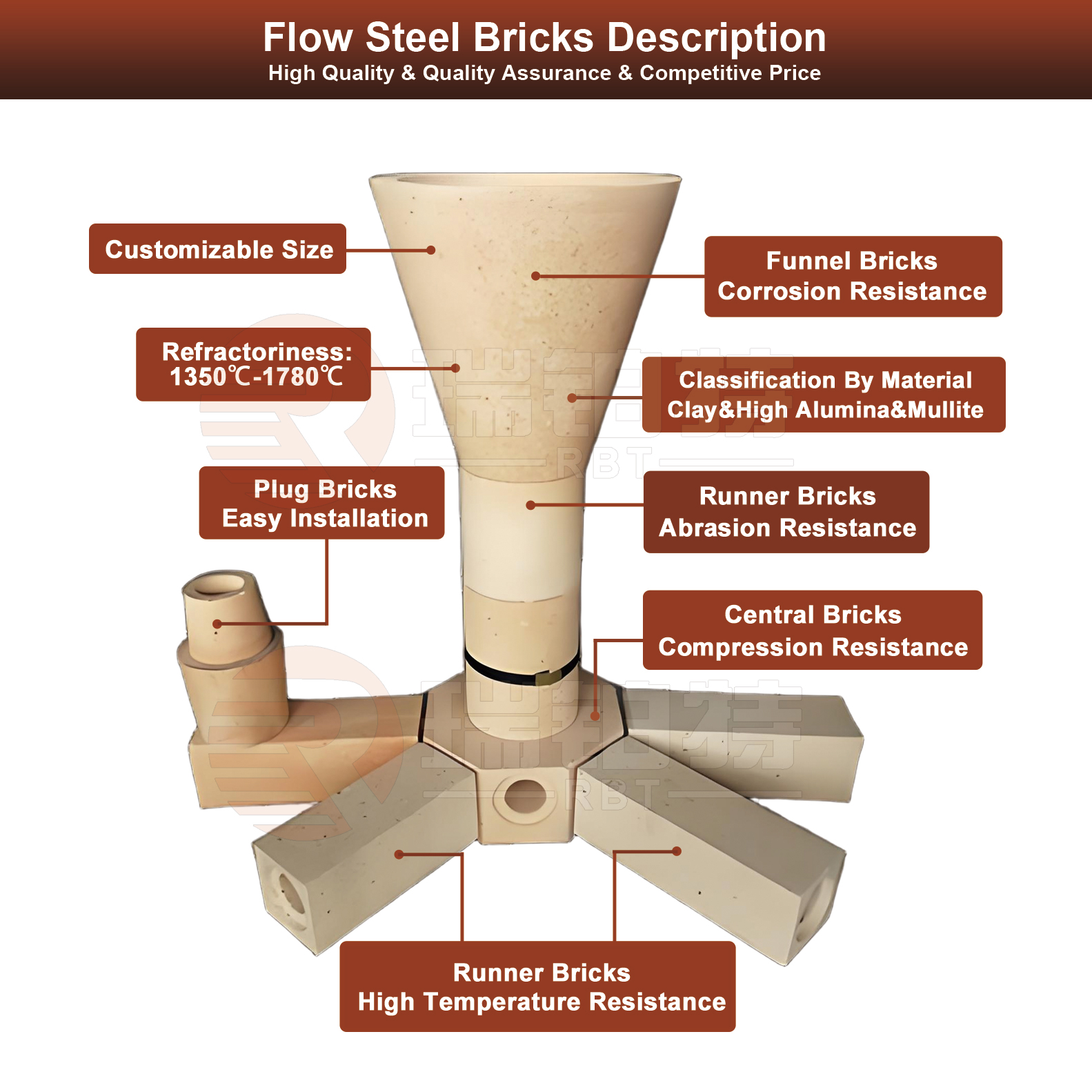

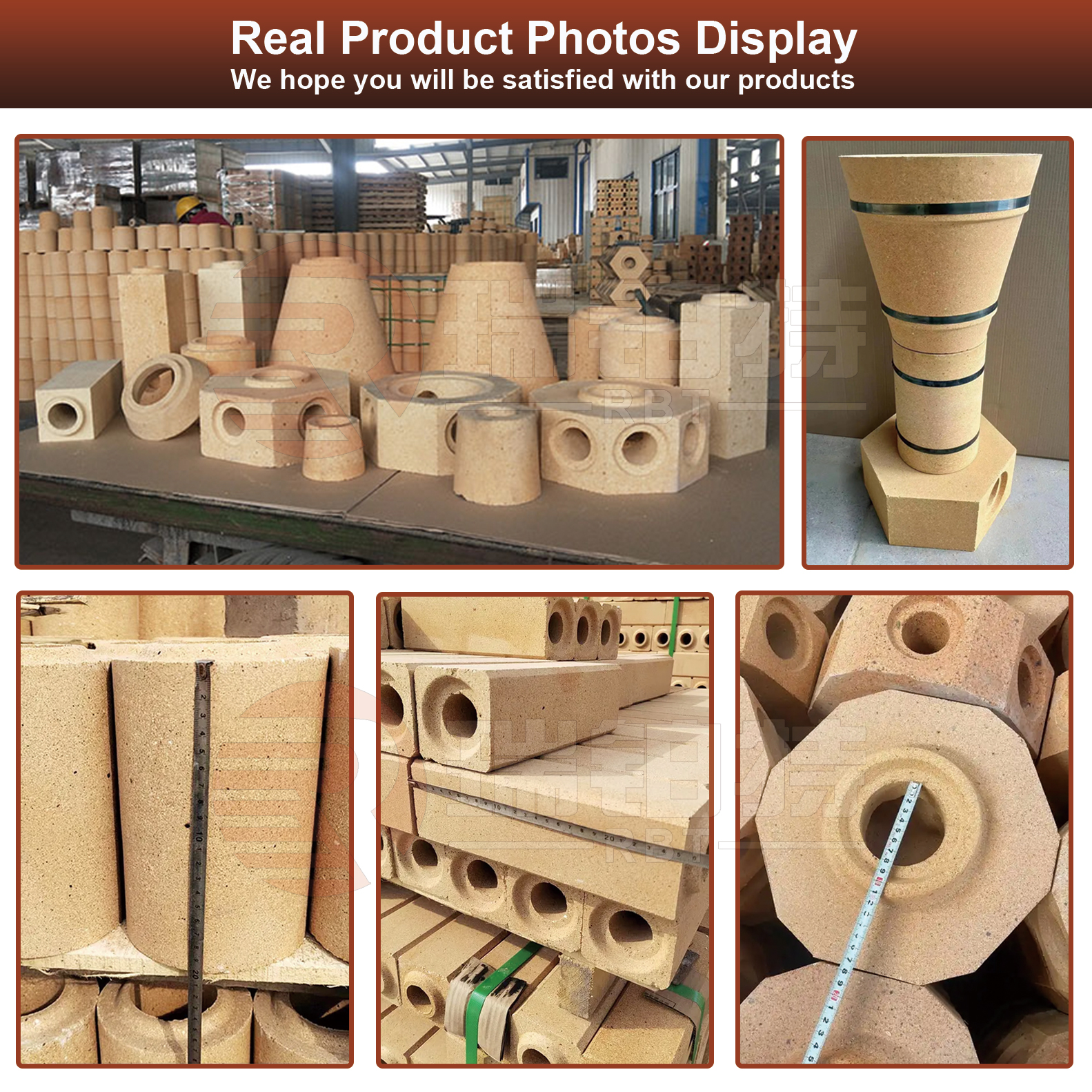

Flow steel bricks refer to hollow refractory bricks that are laid in the grooves of the ingot casting bottom plate to connect the flow steel bricks and the ingot mold, commonly known as runner brick. Mainly used to reduce the resistance of molten steel flow and prevent steel leakage. The main characteristics include high temperature pressure resistance, wear resistance, good fluidity, easy installation and good fire resistance.

1. Classification by material:

(1)Clay: This is the most basic type of flow steel brick, made of ordinary clay. Although the price is low, it is relatively poor in fire resistance and service life, and is suitable for some small steel mills or temporary use scenarios.

(2)High aluminum: This flow steel brick contains a high aluminum content, has excellent fire resistance, and can remain stable in high temperature environments. It is often used in large steel enterprises, especially in steelmaking processes that need to withstand high temperatures for a long time.

(3)Mullite: The surface needle-shaped crystals present a network cross structure, which can effectively prevent erosion by molten steel. It is currently the mainstream material.

2. Classification by functional:

(1)Center Bricks

Used in the core area of molten steel flow, supporting the flow path and requiring high

refractoriness and erosion resistance.

(2)Steel Divider Bricks

Used to divert molten steel to different molds. Common specifications include double, triple, and quadruple holes, depending on process requirements.

(3)Tail Bricks

Located at the end of the steel flow system, they withstand the impact of molten steel and high temperatures and require resistance to fracture.

Product Index

|

Clay&High Alumina

|

|||||||

|

Item

|

RBT-80

|

RBT-75

|

RBT-70

|

RBT-65

|

RBT-55

|

RBT-48

|

RBT-40

|

|

Al2O3(%) ≥

|

80

|

75

|

70

|

65

|

55

|

48

|

40

|

|

Apparent Porosity(%) ≤

|

21(23)

|

24(26)

|

24(26)

|

24(26)

|

22(24)

|

22(24)

|

22(24)

|

|

Cold Crushing Strength(MPa) ≥

|

70(60)

60(50)

|

60(50)

50(40)

|

55(45)

45(35)

|

50(40)

40(30)

|

45(40)

35(30)

|

40(35)

35(30)

|

35(30)

30(25)

|

|

0.2MPa Refractoriness Under Load(℃) ≥

|

1530

|

1520

|

1510

|

1500

|

1450

|

1420

|

1400

|

|

Permanent Linear Change(%)

|

1500℃*2h

|

1500℃*2h

|

1450℃*2h

|

1450℃*2h

|

1450℃*2h

|

1450℃*2h

|

1450℃*2h

|

|

-0.4~0.2

|

-0.4~0.2

|

-0.4~0.1

|

-0.4~0.1

|

-0.4~0.1

|

-0.4~0.1

|

-0.4~0.1

|

|

|

Mullite

|

||

|

Item

|

JM-70

|

JM-62

|

|

Al2O3(%) ≥

|

70

|

62

|

|

Fe2O3(%) ≤

|

1.8

|

1.5

|

|

Refractoriness(℃) ≥

|

1780

|

1760

|

|

Apparent Porosity(%) ≤

|

28

|

26

|

|

Cold Crushing Strength(MPa) ≥

|

25

|

25

|

|

Permanent Linear Change(1500℃*2h)(%)

|

-0.1~+0.4

|

-0.1~+0.4

|

Application

Flow steel bricks are primarily used in the bottom casting process, serving as a channel for molten steel to flow from the ladle to the ingot molds, ensuring smooth distribution of the molten steel to each ingot mold.

Core Function

Flow steel bricks, through their hollow interior, ensure directional flow of molten steel, preventing it from directly impacting the ingot molds and minimizing structural failure caused by localized overheating. Furthermore, their refractory properties allow them to withstand the physical impact and chemical reactions of high-temperature molten steel, preventing impurities from entering the steel and affecting its quality.

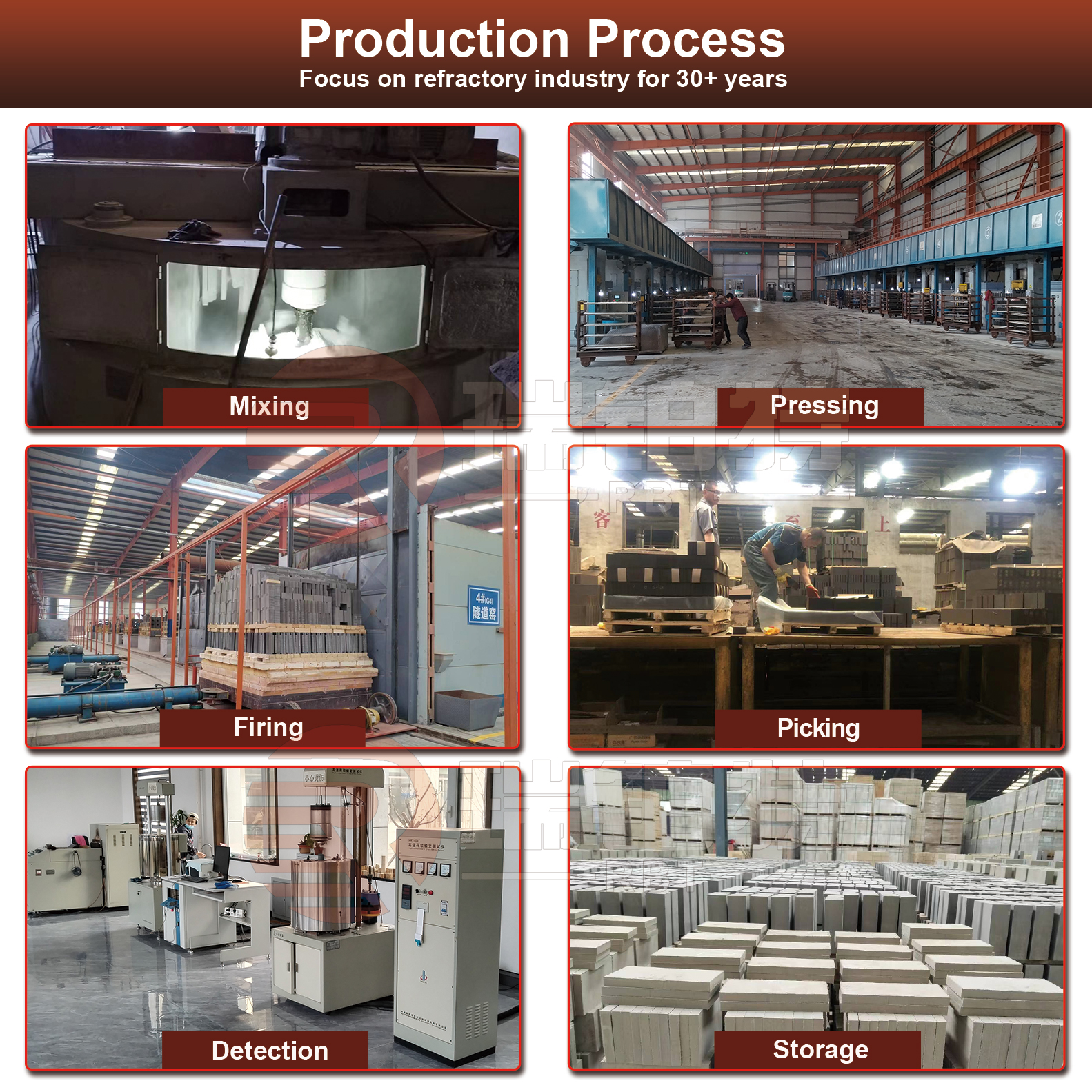

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.