Mullite Bricks&Sillimanite Bricks

Product Information

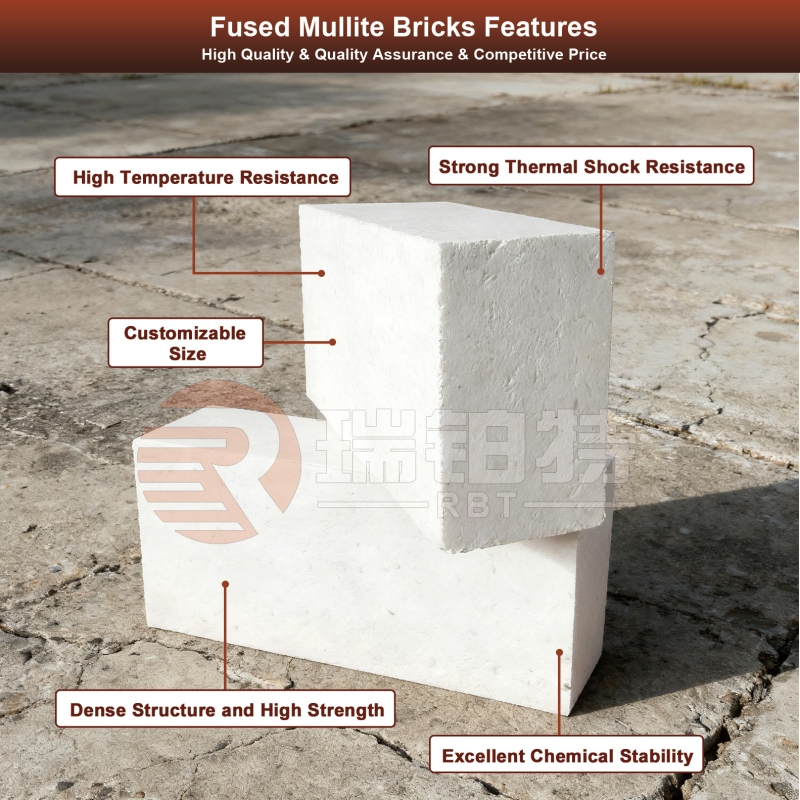

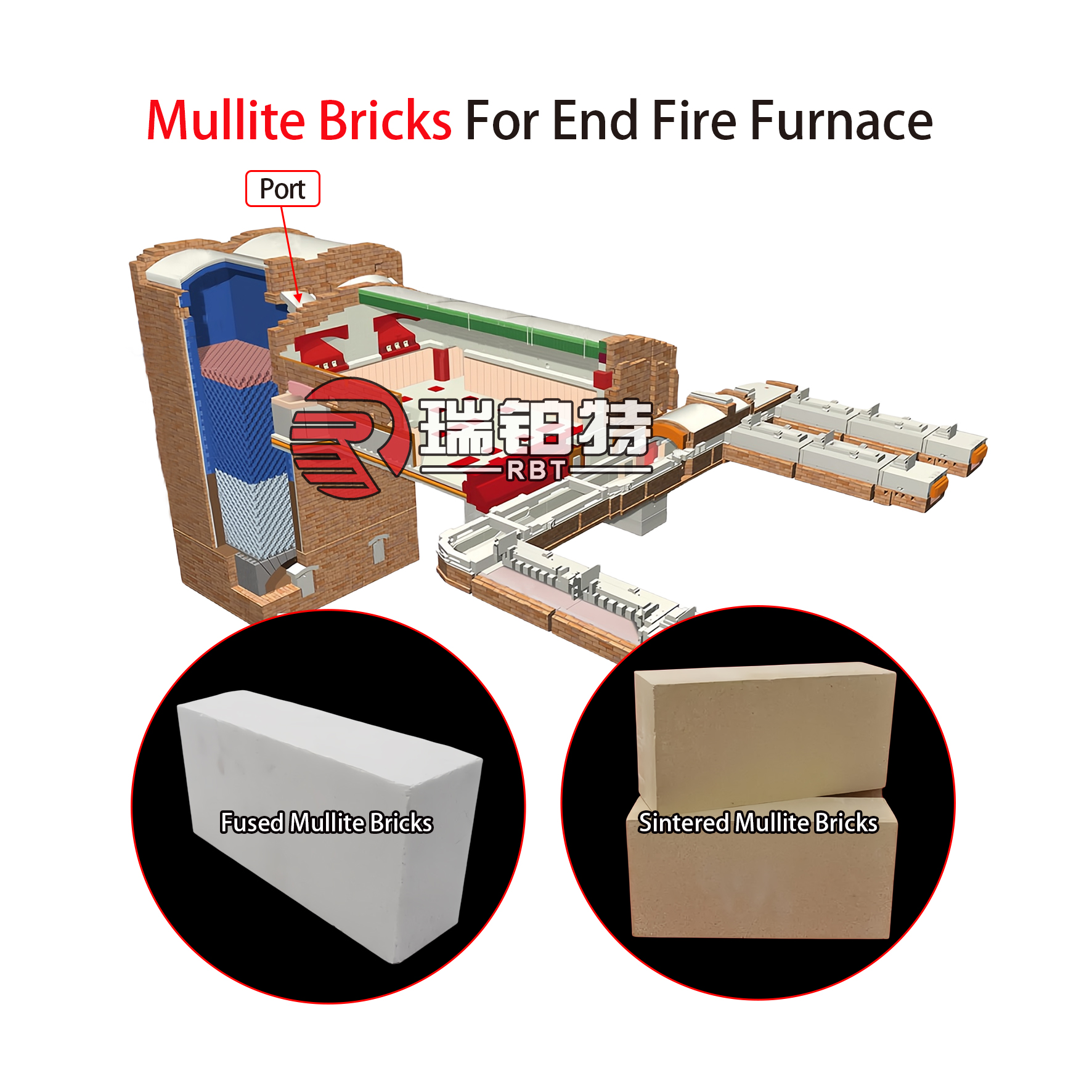

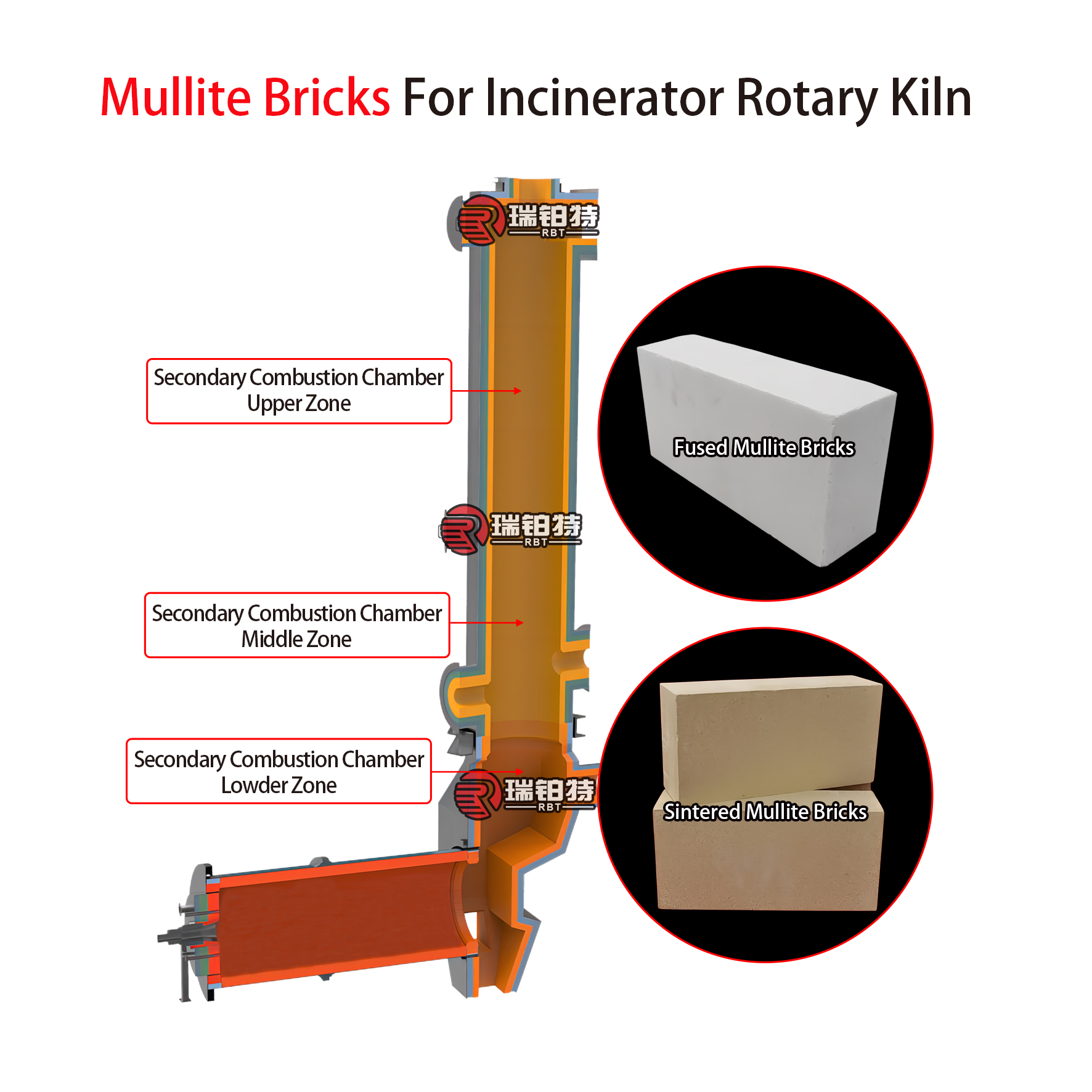

Mullite bricks are a high aluminum refractory with mullite as the main crystal phase. Generally, the content of alumina is between 65% and 75%. In addition to mullite, the minerals with lower alumina content also contain a small amount of vitreous phase and cristobalite. The higher alumina content also contains a small amount of corundum. It is mainly used for hot blast stove top, blast furnace body and bottom, glass furnace regenerator, ceramic kiln, dead corner lining of petroleum cracking system, etc.

Classification: Three Low Mullite/Sintered Mullite/Fused Mullite/Sillimanite Mullite

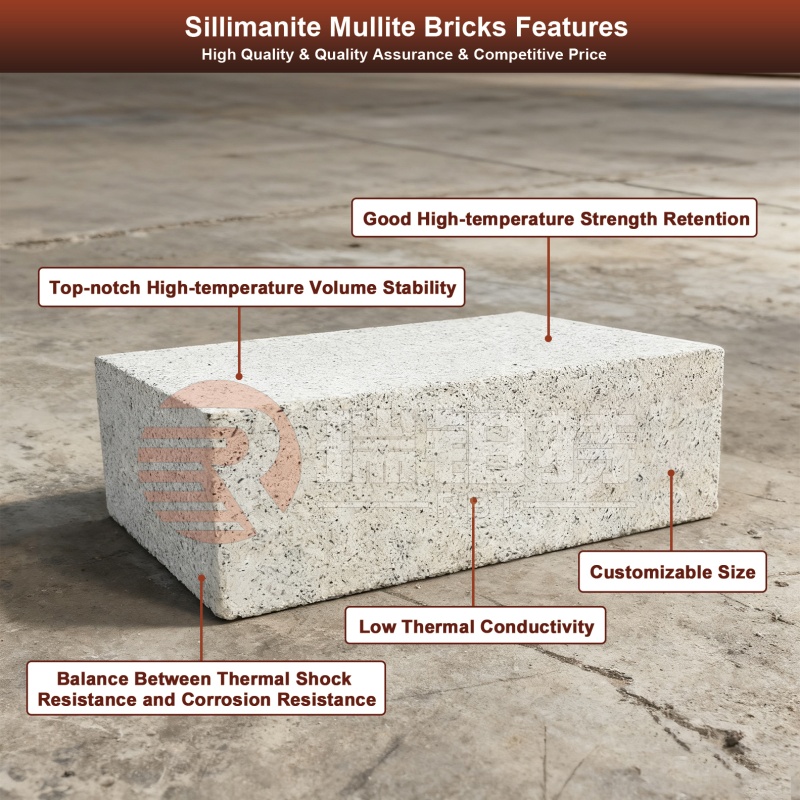

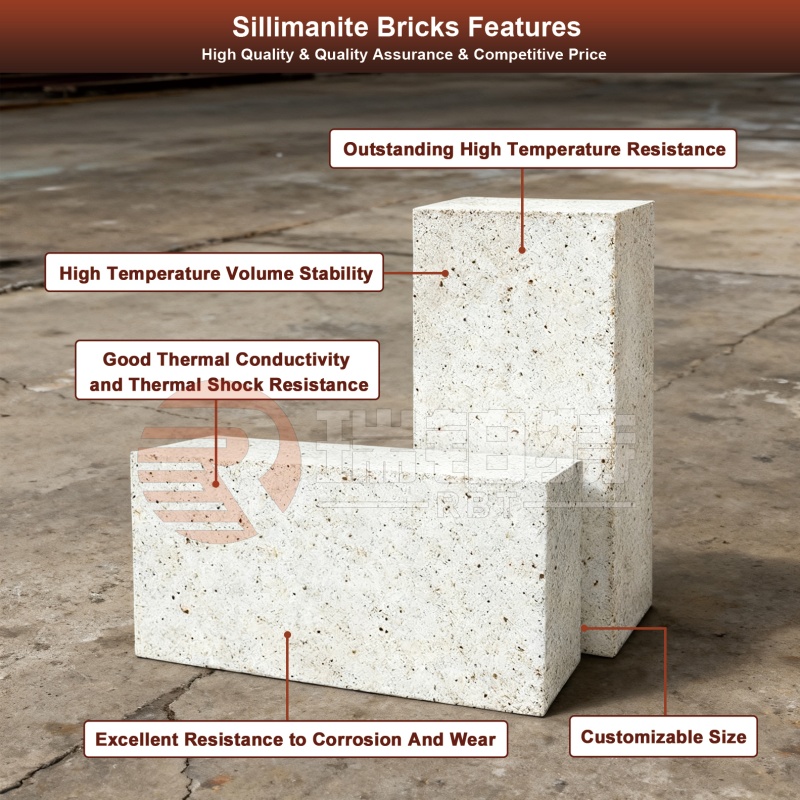

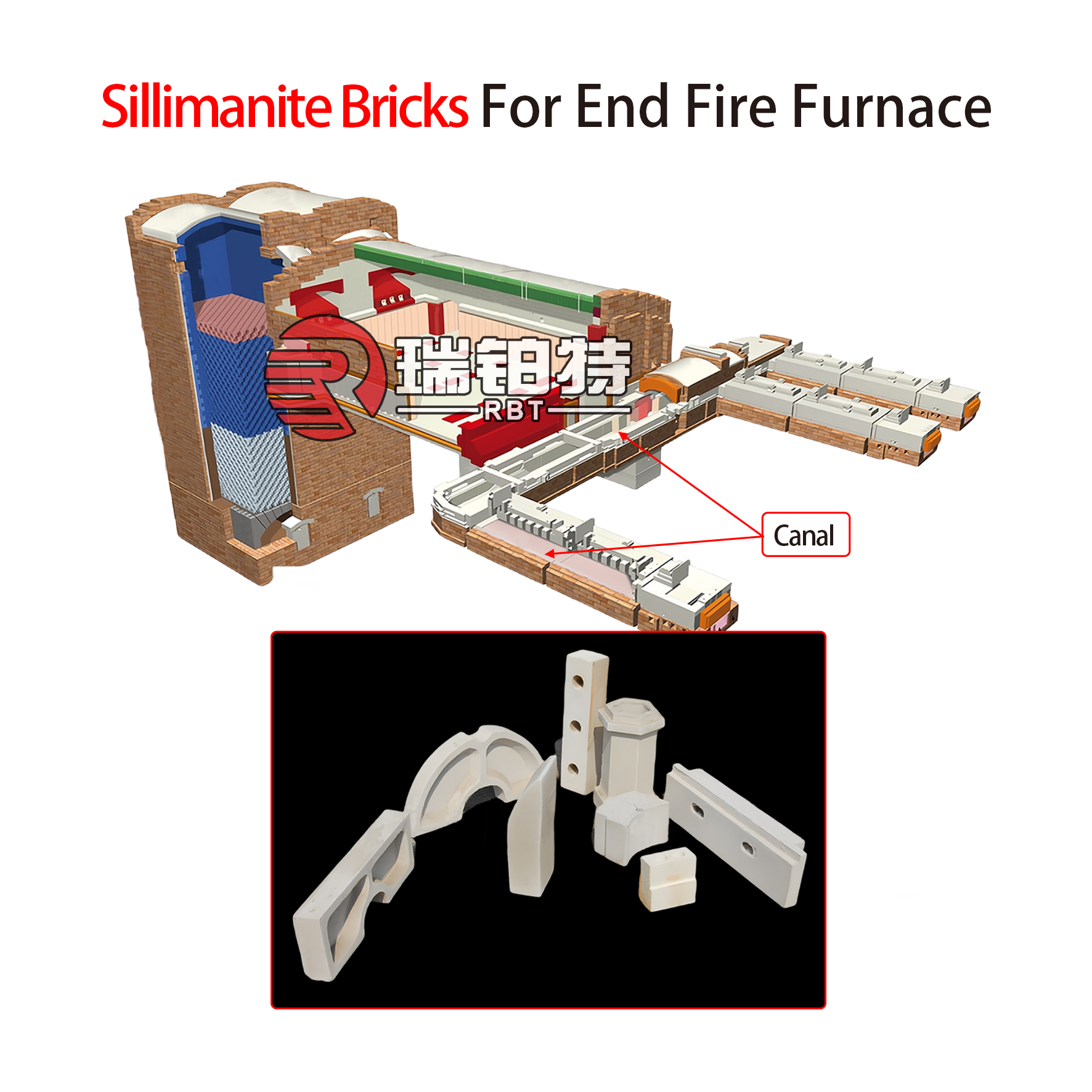

Sillimanite bricks are refractory bricks with good properties made from sillimanite minerals by high temperature sintering or slurry casting. Sillimanite is converted into mullite and free silica after high temperature calcination. It is generally produced by high temperature sintering and slurry casting.

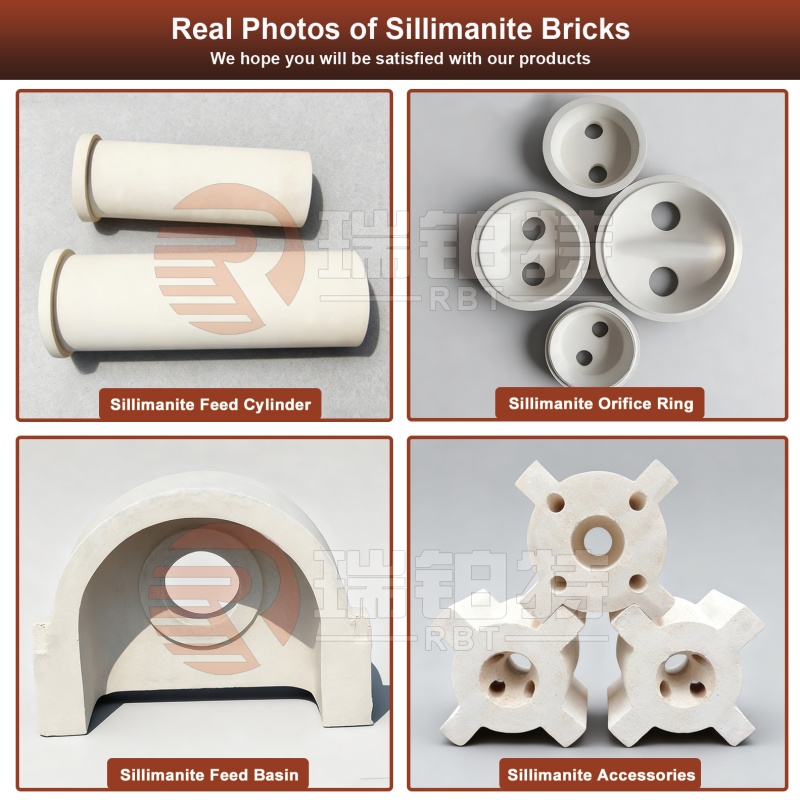

Features: Good thermal stability at high temperature, resistance to glass liquid erosion, small pollution to glass liquid, and are mostly suitable for feeding channel, feeding machine, tube pulling machine and other equipment in glass industry, which can significantly improve productivity.

Products: Channel brick, flow trough, rotary pipe, feed basin, orifice ring, stirring paddle, punch, feed cylinder, fire block slag brick, damper block, arch brick, feed basin cover, through-hole brick, burner brick, beam, cover brick and other varieties and specifications.

Product Index

|

Products

|

Three Low Mullite

|

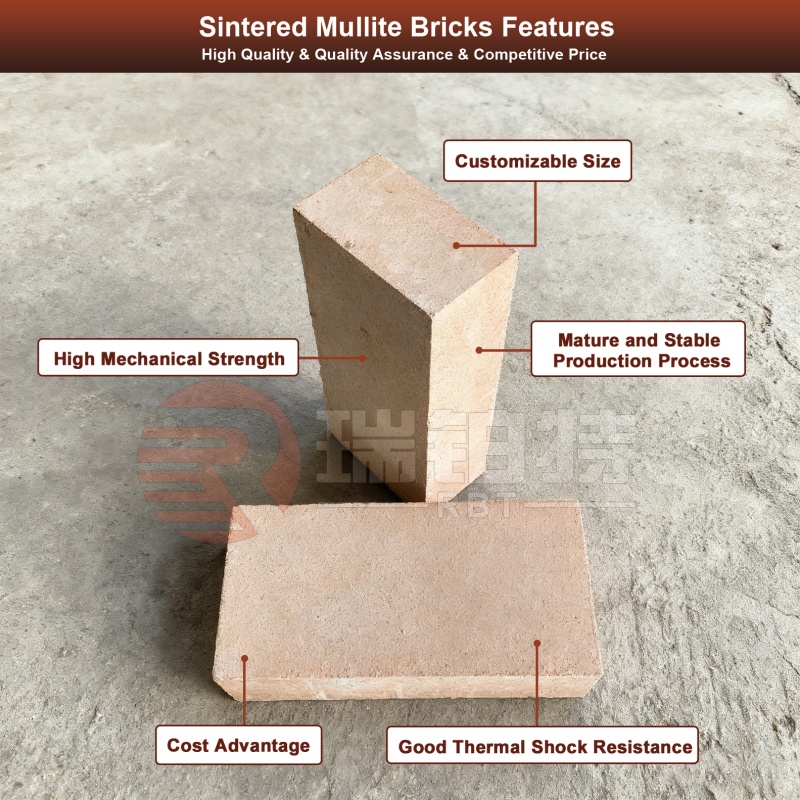

Sintered Mullite

|

Sillimanite Mullite

|

Fused Mullite

|

||||

|

Index

|

RBTM-47

|

RBTM-65

|

RBTM-70

|

RBTM-75

|

RBTA-60

|

RBTA-65

|

RBTFM-75

|

|

|

Refractoriness(℃) ≥

|

1790

|

1790

|

1790

|

1790

|

1790

|

1790

|

1810

|

|

|

Bulk Density(g/cm3) ≥

|

2.42

|

2.45

|

2.50

|

2.60

|

2.48

|

2.5

|

2.70

|

|

|

Apparent Porosity(%) ≤

|

12

|

18

|

18

|

17

|

18

|

18

|

16

|

|

|

Cold Crushing Strength(MPa)

|

60

|

60

|

70

|

80

|

70

|

70

|

90

|

|

|

Permanent Linear Change(%)

|

1400°×2h

|

+0.1

-0.1

|

|

|

|

|

|

|

|

1500°×2h

|

|

+0.1

-0.4

|

+0.1

-0.4

|

+0.1

-0.4

|

+1

-0.2

|

±0.2

|

±0.1

|

|

|

Refractoriness Under Load@0.2MPa(℃) ≥

|

1520

|

1580

|

1600

|

1600

|

1600

|

1620

|

1700

|

|

|

Creep Rate@0.2MPa

1200°×2h(%) ≤

|

0.1

|

―

|

―

|

―

|

―

|

―

|

―

|

|

|

Al2O3(%) ≥

|

47

|

64

|

68

|

72

|

60

|

65

|

75

|

|

|

Fe2O3(%) ≤

|

1.2

|

0.8

|

0.8

|

0.7

|

1.0

|

0.8

|

0.5

|

|

Application

Mullite Bricks:

Ceramic Industry: Used for kiln shelves, pushers, kiln walls, and burner bricks in ceramic kilns, withstanding temperatures above 1600℃ and frequent temperature changes, reducing kiln wear and ensuring product firing quality.

Metallurgical Industry: Suitable for lining hot blast stoves in steel plants and furnaces in non-ferrous metal smelting, resisting erosion from molten metal and slag, while possessing good high-temperature structural stability.

Glass Industry: Used as lining bricks for the side walls, bottom, and flow channels of glass kilns, withstanding the scouring of molten glass and high-temperature corrosion, extending the service life of the kiln, and ensuring continuous and stable glass production.

Other High-Temperature Applications: Used for lining waste incinerators, industrial boilers, and high-temperature testing equipment in the aerospace and electronics industries, adaptable to complex and harsh high-temperature environments.

Sillimanite Bricks:

Iron and Steel Industry: Used as checker bricks in blast furnace hot blast stoves and as linings for hot blast pipes, capable of withstanding temperatures above 1300℃ and airflow erosion, extending equipment lifespan.

Non-ferrous Metal Smelting: Suitable for sidewalls of aluminum electrolytic cells and linings of copper-nickel smelting furnaces, resisting erosion from molten metal and slag, ensuring stable smelting.

Ceramics and Glass Industry: Used as kiln roof plates, pusher plates, and burner lining bricks, resistant to frequent heating and cooling, reducing kiln wear.

Other High-Temperature Equipment: Used as linings for waste incinerators, industrial boilers, and high-temperature reactors in the chemical industry, adaptable to complex operating conditions.

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.