Introduction

In high-temperature industries—from steelmaking to glass production—refractory materials are the backbone of safe and efficient operations. Among these, mullite bricks stand out for their exceptional thermal stability, corrosion resistance, and mechanical strength. Understanding their classification and applications is critical for businesses seeking to optimize equipment lifespan and reduce operational costs. This article breaks down the key types of mullite bricks and their real-world uses, helping you make informed decisions for your industrial needs.

Classification of Mullite Bricks

Mullite bricks are categorized based on manufacturing processes and added components, each tailored to specific industrial demands.

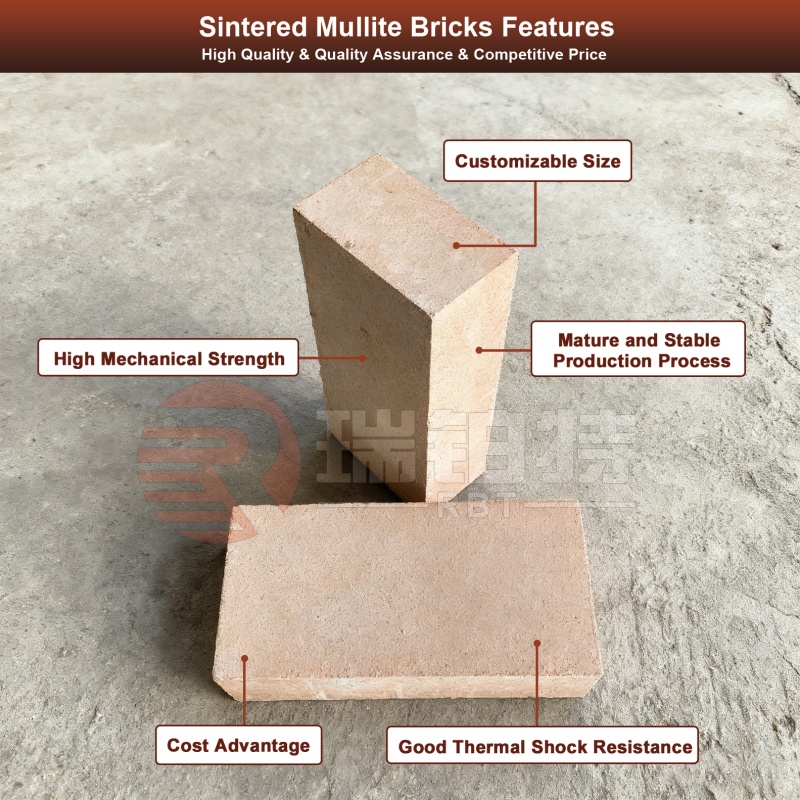

1. Sintered Mullite Bricks

Made by mixing high-purity alumina and silica, shaping the mixture, and sintering it at temperatures above 1600°C, sintered mullite bricks boast a dense structure and low porosity (typically below 15%). These traits give them excellent wear resistance and thermal shock resistance—ideal for environments with frequent temperature fluctuations. Common uses include linings for ceramic kilns, blast furnace hot blast stoves, and boiler combustion chambers.

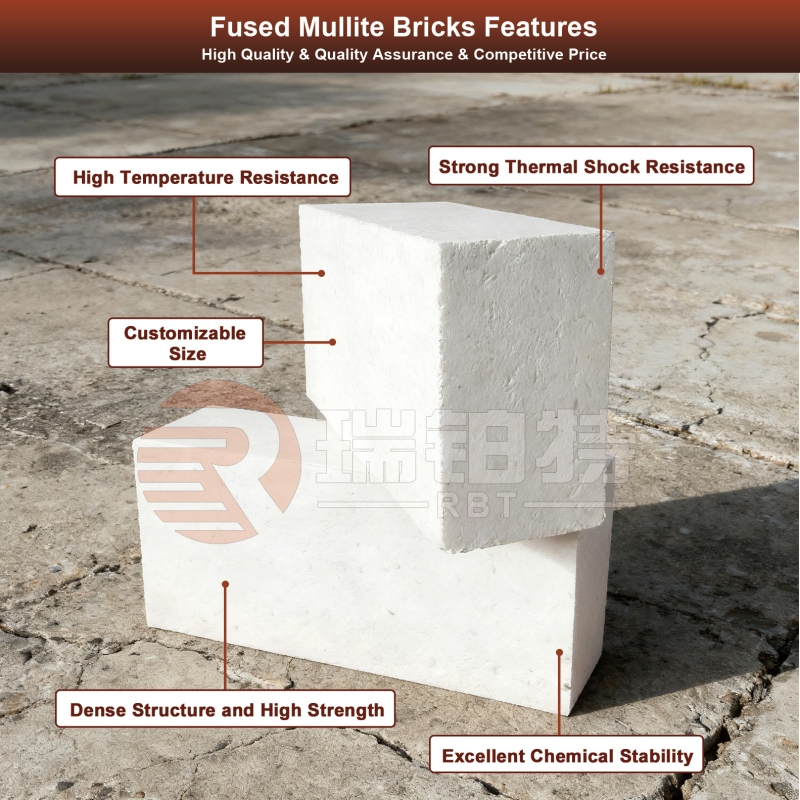

2. Fused-cast Mullite Bricks

Produced by melting raw materials (alumina, silica) in an electric arc furnace (over 2000°C) and casting the molten mixture into molds, fused-cast mullite bricks have ultra-low impurity levels and high crystalline purity. Their superior resistance to chemical erosion (e.g., from molten glass or slags) makes them a top choice for glass furnace regenerators, float glass tin baths, and other equipment exposed to aggressive molten media.

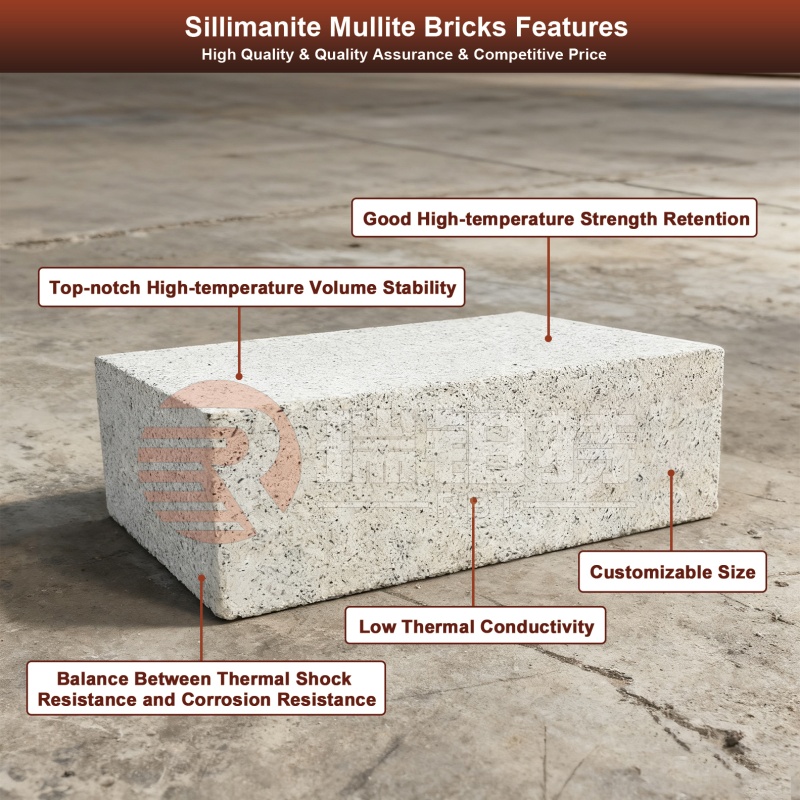

3. Lightweight Mullite Bricks

Created by adding pore-forming agents (e.g., sawdust, graphite) during production, lightweight mullite bricks have a porosity of 40–60% and a much lower density than sintered or fused-cast types. Their key advantage is low thermal conductivity (0.4–1.2 W/(m·K)), which reduces heat loss. They are widely used as insulation layers in kilns, furnaces, and heat treatment equipment, where weight and energy efficiency are priorities.

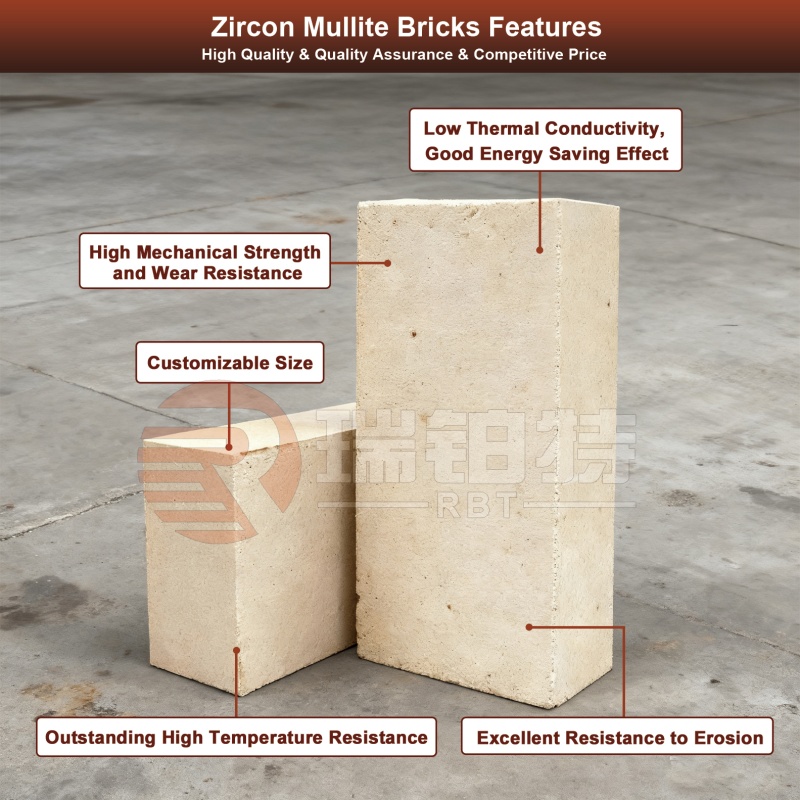

4. Zircon Mullite Bricks

By incorporating zircon (ZrSiO₄) into the raw material mix, zircon mullite bricks gain enhanced high-temperature performance—they can withstand temperatures up to 1750°C and resist erosion from acidic slags. This makes them suitable for harsh environments like non-ferrous metal smelting furnaces (e.g., aluminum reduction cells) and cement rotary kiln burning zones.

Applications of Mullite Bricks

Mullite bricks` versatility makes them indispensable across multiple high-temperature industries.

1. Steel Industry

Steel production involves extreme temperatures (up to 1800°C) and corrosive slags. Sintered mullite bricks line hot blast stoves, where their thermal shock resistance prevents cracking from rapid heating/cooling. Fused-cast variants protect ladles and tundishes, reducing slag erosion and extending equipment life by 20–30% compared to traditional refractories.

2. Cement Industry

Cement rotary kilns operate at 1450–1600°C, with alkaline slags posing a major erosion risk. Zircon mullite bricks line the kiln`s burning zone, resisting alkali attacks and maintaining structural integrity. Lightweight mullite bricks also act as insulation layers, cutting energy consumption by 10–15%.

3. Glass Industry

Molten glass (1500–1600°C) is highly corrosive, making fused-cast mullite bricks essential for glass furnace regenerators and tank linings. They prevent glass contamination and extend furnace runtime to 5–8 years, up from 3–5 years with other materials.

4. Other Industries

In non-ferrous metal smelting (aluminum, copper), zircon mullite bricks resist molten metal and slag erosion. In petrochemicals, sintered mullite bricks line cracking furnaces due to their thermal stability. In ceramics, lightweight mullite bricks insulate kilns, lowering energy use.

Conclusion

Mullite bricks` diverse types—sintered, fused-cast, lightweight, and zircon—meet the unique needs of high-temperature industries. From boosting steel furnace efficiency to extending glass furnace life, they deliver tangible benefits: longer equipment lifespan, lower energy costs, and reduced downtime. As industries pursue higher productivity and sustainability, mullite bricks will remain a key solution. Choose the right type for your application, and unlock their full potential.

Post time: Oct-31-2025