In industrial operations where equipment faces relentless abrasion, corrosion, and impact, finding reliable protective solutions is critical to minimizing downtime and maximizing productivity. Alumina Ceramic Mosaic Tiles emerge as a game-changer, blending advanced material science with modular design to deliver unmatched durability and versatility. Engineered for extreme conditions, these tiles are redefining equipment protection across key industries worldwide.

Modular Precision: The Power of Mosaic Design

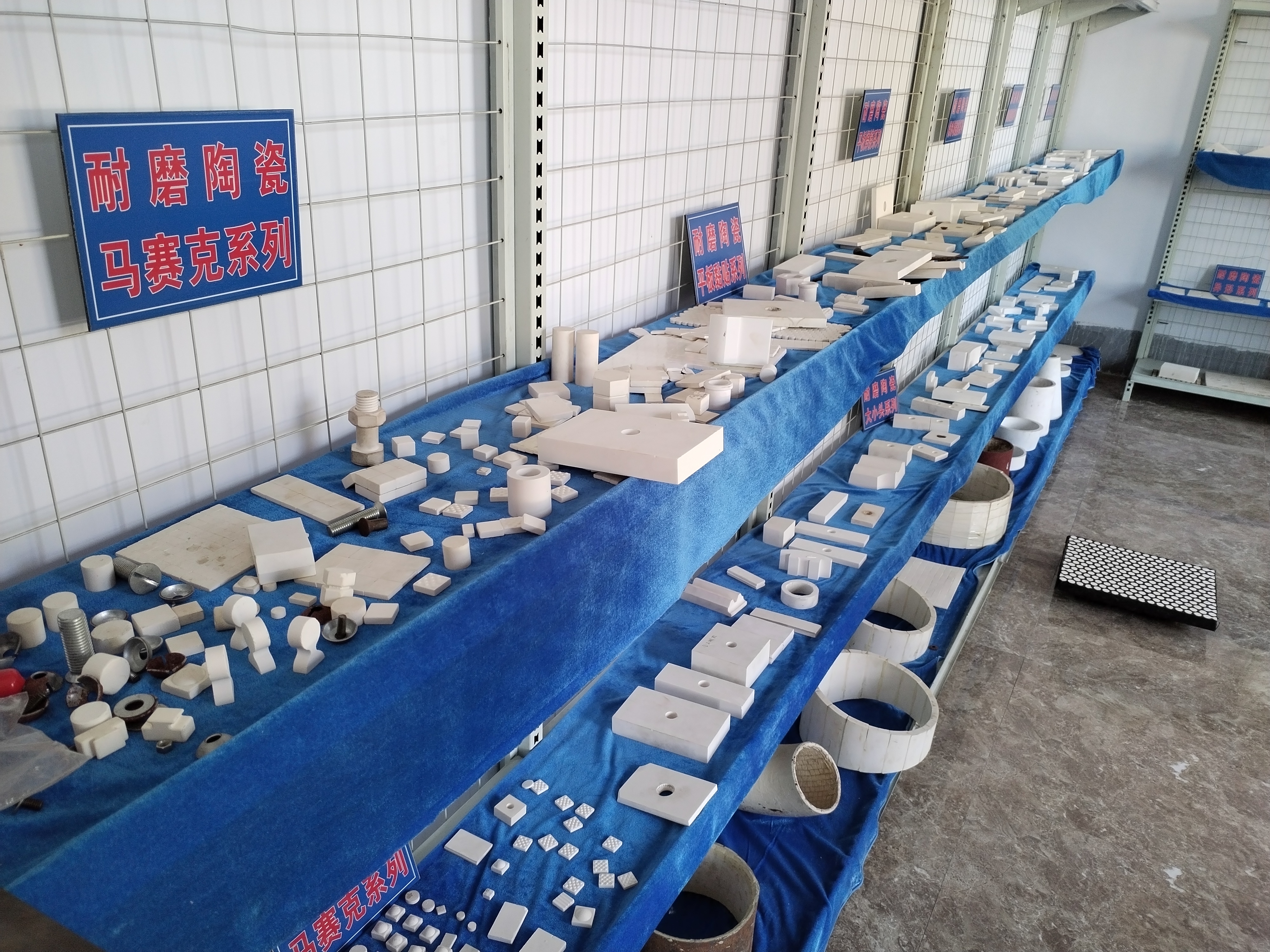

At the core of alumina ceramic mosaic tiles lies their innovative modular structure. Crafted as small, precision-engineered tiles (typically 10mm–50mm in size), they offer unparalleled flexibility in installation. Unlike rigid large-scale liners, these mosaic tiles can be customized to fit any equipment shape—from curved pipes and conical hoppers to irregularly shaped chutes and mill inner walls. Each tile is manufactured with tight dimensional tolerances, ensuring seamless bonding that creates a continuous, impenetrable protective layer.

This modularity also simplifies maintenance: if a single tile is damaged (a rare occurrence), it can be replaced individually without removing the entire liner system, reducing downtime and repair costs significantly. Whether retrofitting existing equipment or integrating into new machinery, alumina ceramic mosaic tiles adapt to your needs with unmatched precision.

Unrivaled Wear & Corrosion Resistance

Alumina ceramic mosaic tiles are forged from high-purity alumina (90%–99% Al₂O₃), granting them exceptional mechanical properties. With a Mohs hardness of 9—second only to diamond—they outperform traditional materials like steel, rubber, or polymer liners in resisting abrasion from rocks, minerals, and granular materials. In mining operations, for example, they withstand the constant impact of ore in crushers and conveyors, maintaining their integrity even after years of heavy use.

Beyond wear resistance, these tiles excel in harsh chemical environments. They are inert to most acids, alkalis, and solvents, making them ideal for chemical processing plants, where corrosive fluids and gases would degrade lesser materials. Combined with their ability to withstand temperatures up to 1600°C, they’re a reliable choice for high-heat applications like metallurgical furnaces and cement kilns.

Tailored for Key Industrial Sectors

The versatility of alumina ceramic mosaic tiles makes them indispensable across industries plagued by equipment wear. Here’s how they drive value in critical sectors:

Mining & Minerals: Protect crushers, ball mills, and transfer chutes from abrasive ore, reducing equipment replacement cycles by 3–5x.

Cement Production: Line raw material mills, clinker coolers, and dust collection ducts to resist the erosive force of cement particles, ensuring uninterrupted production.

Chemical Processing: Safeguard reactor walls, agitator blades, and storage tanks from corrosive media, preventing contamination and extending asset life.

Power Generation: Shield coal conveying systems, ash handling pipes, and boiler components from fly ash abrasion, lowering maintenance costs for power plants.

Waste Management: Line waste incinerator liners and recycling equipment to withstand abrasive and high-temperature waste materials.

No matter the application, these tiles are engineered to solve your most pressing wear challenges.

A Cost-Effective Investment in Long-Term Efficiency

While alumina ceramic mosaic tiles represent a premium upfront investment, their lifecycle cost savings are undeniable. By reducing equipment downtime (which can cost industrial operations thousands per hour), minimizing replacement parts, and extending machinery life, they deliver a rapid return on investment (ROI)—often within 6–12 months.

Compared to steel liners that require frequent welding and replacement, or rubber liners that degrade quickly in high temperatures, alumina mosaic tiles offer “fit-and-forget” performance. Their low maintenance needs and long service life (5–10 years in most applications) make them a smart choice for businesses focused on sustainable, cost-efficient operations.

Ready to Transform Your Equipment Protection?

If your operations are held back by frequent equipment wear, high maintenance bills, or unplanned downtime, alumina ceramic mosaic tiles are the solution you need. Their modular design, industrial-grade durability, and sector-specific performance make them the gold standard in wear protection.

Contact our team today to discuss your unique application requirements. We’ll provide customized tile specifications, installation guidance, and a free performance analysis to show how much you could save. Let alumina ceramic mosaic tiles turn your equipment from a liability into a long-term asset—because in industrial operations, durability isn’t an option—it`s a necessity.

Post time: Jul-23-2025