In the world of high-temperature industrial operations, finding reliable and durable refractory materials is crucial. Whether you`re running a glass manufacturing plant, a metallurgical facility, or a cement production line, the performance of your refractory products directly impacts productivity, safety, and cost-efficiency. This is where AZS Bricks stand out as a game-changer.

What Are AZS Bricks, and Why Do They Matter?

AZS Bricks, also known as Alumina-Zirconia-Silica Bricks, are a premium type of refractory brick engineered to withstand extreme temperatures (up to 1700°C or higher) and harsh chemical environments. Composed of high-purity alumina, zirconia, and silica, these bricks offer exceptional thermal stability, low thermal expansion, and superior resistance to corrosion, erosion, and thermal shock.

Unlike traditional refractory bricks that may crack, wear out, or fail prematurely under intense heat, AZS Bricks maintain their structural integrity even in the most demanding conditions. This durability translates to fewer replacements, less downtime, and lower long-term maintenance costs for your business.

Key Applications: Where AZS Bricks Shine

AZS Bricks are not a one-size-fits-all solution—they`re tailored to meet the unique needs of specific high-temperature industries. Here are their most critical uses:

1. Glass Manufacturing Industry

Glass production involves melting raw materials at temperatures exceeding 1500°C, and the refractory lining of glass furnaces is constantly exposed to molten glass, corrosive fluxes, and thermal cycling. AZS Bricks are the top choice for:

Furnace Crowns & Sidewalls: Their high zirconia content resists corrosion from molten glass and reduces the risk of contamination, ensuring consistent glass quality.

Regenerators & Checkers: They withstand rapid temperature changes (thermal shock) during the furnace`s heating and cooling cycles, extending the lifespan of these critical components.

Feeder Channels: AZS Bricks prevent erosion from flowing molten glass, minimizing blockages and ensuring a smooth production process.

For glass manufacturers, using AZS Bricks means fewer furnace shutdowns, better glass clarity, and reduced waste—directly boosting your bottom line.

2. Metallurgical & Steel Production

In steel mills and non-ferrous metal smelters, AZS Bricks play a vital role in lining equipment that handles molten metals (e.g., steel, aluminum, copper) and high-temperature gases. Key applications include:

Tundishes & Ladles: They resist corrosion from molten metal and slag, preventing metal contamination and ensuring clean, high-quality end products.

Electric Arc Furnace (EAF) Linings: Their thermal stability withstands the extreme heat of electric arc melting, reducing lining wear and extending furnace life.

Annealing Furnaces: AZS Bricks maintain uniform temperatures, critical for heat-treating metals to achieve desired strength and ductility.

By choosing AZS Bricks, metallurgical facilities can increase production efficiency, reduce metal loss, and comply with strict quality standards.

3. Cement & Lime Kilns

Cement and lime production require kilns that operate at temperatures up to 1450°C, with linings exposed to abrasive materials (e.g., limestone, clinker) and alkaline gases. AZS Bricks excel here because:

They resist abrasion from moving clinker, reducing lining thickness loss over time.

Their low thermal conductivity helps retain heat inside the kiln, improving energy efficiency and lowering fuel costs.

They withstand alkaline corrosion from cement kiln dust (CKD), preventing lining degradation and kiln shell damage.

For cement producers, AZS Bricks mean longer kiln runs, lower energy consumption, and consistent clinker quality.

4. Other High-Temperature Industries

AZS Bricks also find applications in:

Petrochemical Refineries: Lining cracking furnaces and reformers that process hydrocarbons at high temperatures.

Waste Incineration Plants: Withstanding the heat and corrosive byproducts of waste combustion.

Ceramic Kilns: Ensuring uniform heating for high-temperature ceramic firing.

Why Choose Our AZS Bricks Over Competitors?

Not all AZS Bricks are created equal. Our products stand out for three key reasons:

Premium Raw Materials: We use high-purity alumina, zirconia, and silica sourced from trusted suppliers, ensuring consistent quality and performance.

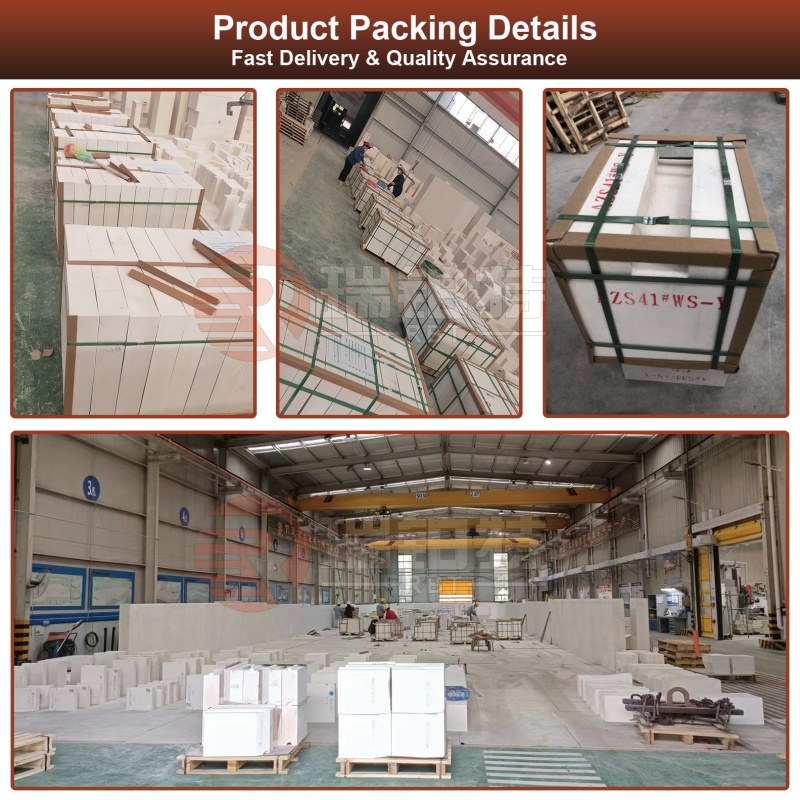

Advanced Manufacturing Process: Our bricks are formed using state-of-the-art pressing and sintering techniques, resulting in dense, uniform structures that resist wear and corrosion.

Customization: We offer AZS Bricks in various sizes, shapes, and compositions to fit your specific equipment and application needs—no more forcing a “standard” brick to work for your unique setup.

Plus, our team of refractory experts provides full technical support, from material selection to installation guidance, ensuring you get the most out of your AZS Bricks.

Ready to Upgrade Your Refractory Solution?

If you`re tired of frequent refractory replacements, costly downtime, or inconsistent product quality, it`s time to switch to AZS Bricks. Our products are trusted by leading manufacturers worldwide for their durability, performance, and value.

Contact us today for a free quote or to discuss how our AZS Bricks can solve your high-temperature challenges. Let`s build a more efficient, reliable, and profitable operation—together.

Post time: Oct-15-2025