In the field of industrial pipeline insulation, choosing an insulation material with excellent performance, safety and reliability is crucial. It is not only related to the efficient use of energy, but also directly affects the safety and stability of the production environment. Calcium silicate pipe, with its excellent comprehensive performance, is becoming the preferred insulation material for more and more industrial projects, providing all-round insulation protection for various pipeline systems.

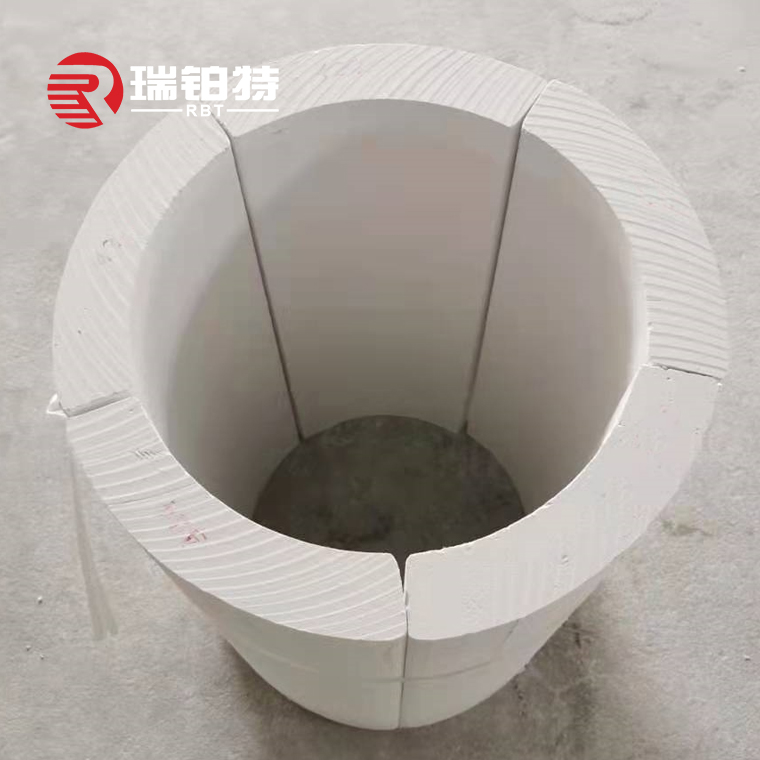

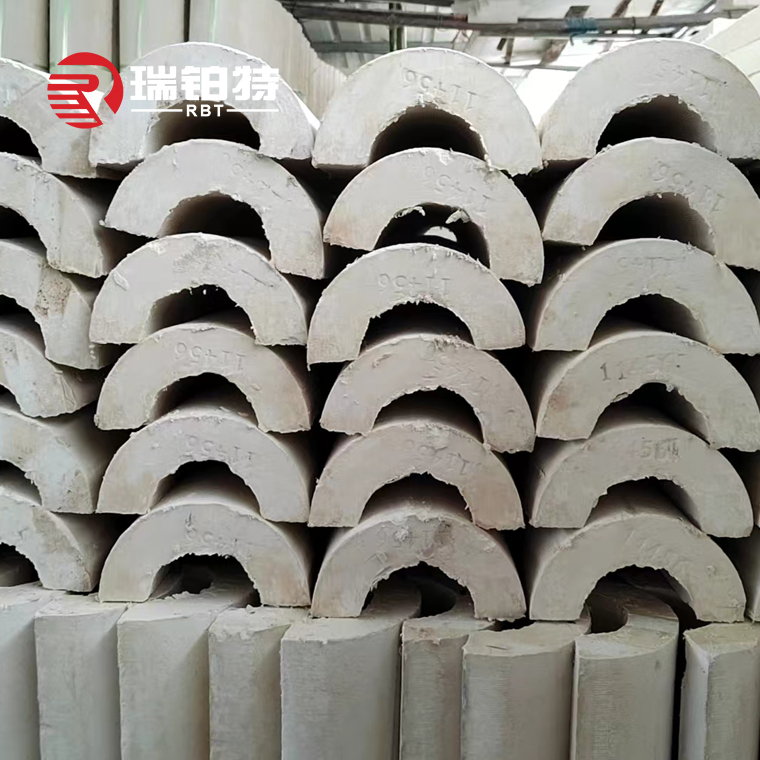

Calcium silicate pipe is mainly made of calcium silicate through advanced production processes and has excellent thermal insulation performance. Its unique porous structure can effectively prevent heat transfer. Whether it is heat loss from high-temperature pipelines or cold loss from low-temperature pipelines, it can be significantly controlled. In industrial production, this means that energy consumption can be greatly reduced, energy utilization efficiency can be improved, thereby saving a lot of operating costs for enterprises. In the long run, the energy-saving benefits brought by calcium silicate pipes are considerable, helping enterprises achieve green and sustainable development.

In addition to excellent insulation performance, fire and moisture resistance is another highlight of calcium silicate pipes. It is a non-combustible material. It will not burn in high-temperature environments nor release toxic and harmful gases, which can effectively delay the spread of fire and provide important safety guarantees for industrial production. At the same time, calcium silicate pipe has good moisture resistance. Even when used in humid environments, there will be no problems such as moisture deformation and reduced insulation performance, ensuring the long-term stable operation of the pipeline insulation system. This feature makes it widely used in humid and rainy areas, underground pipelines and industrial places with moisture-proof requirements.

Calcium silicate pipes also have the characteristics of high strength and wear resistance. It can withstand a certain degree of external impact and pipeline self-weight, is not easy to be damaged, and does not require frequent maintenance and replacement after installation, reducing downtime losses and maintenance costs caused by material damage. Moreover, its surface is flat and smooth, which is easy to cut, trim and splice during installation, and can meet the insulation needs of pipelines with different diameters and shapes, greatly improving construction efficiency and shortening the project cycle.

In terms of application scope, calcium silicate pipes cover almost many aspects of the industrial field. In the power industry, it can be used for insulation of power plant steam pipelines and thermal pipelines; in the chemical industry, it is suitable for insulation protection of various chemical medium transmission pipelines; in the metallurgical industry, it can provide effective insulation for high-temperature smelting pipelines; in addition, calcium silicate pipes also play an important role in pipeline insulation in building heating, air conditioning and refrigeration and other fields.

Choosing calcium silicate pipe means choosing an efficient, safe and durable pipeline insulation solution. It can not only bring significant economic benefits to your project, but also ensure the safety and stability of the production process. Whether you are planning a new industrial project or need to upgrade and transform the existing pipeline insulation system, calcium silicate pipe will be your ideal choice.

Contact us immediately to learn more about product information and application solutions of calcium silicate pipes, let calcium silicate pipes safeguard your industrial projects and create an efficient and energy-saving production environment together!

Post time: Jul-18-2025