1. High-aluminum castable: High-aluminum castable is mainly composed of alumina (Al2O3) and has high refractoriness, slag resistance and thermal shock resistance. It is widely used in high-temperature furnaces and hearths in the steel, non-ferrous metals, chemical and other industries.

2. Steel fiber reinforced castable: Steel fiber reinforced castable is based on ordinary castables and steel fibers are added to enhance its thermal shock resistance, wear resistance and slag resistance. It is mainly used in furnaces, furnace bottoms and other parts in the steel, metallurgy, petrochemical and other industries.

3. Mullite castable: Mullite castable is mainly composed of mullite (MgO·SiO2) and has good wear resistance, refractoriness and slag resistance. It is commonly used in key parts such as steelmaking furnaces and converters in the steel, metallurgy and other industries.

4. Silicon carbide castable: Silicon carbide castable is mainly composed of silicon carbide (SiC) and has excellent wear resistance, slag resistance and thermal shock resistance. Widely used in high-temperature furnaces, furnace beds and other parts of non-ferrous metals, chemicals, ceramics and other industries.

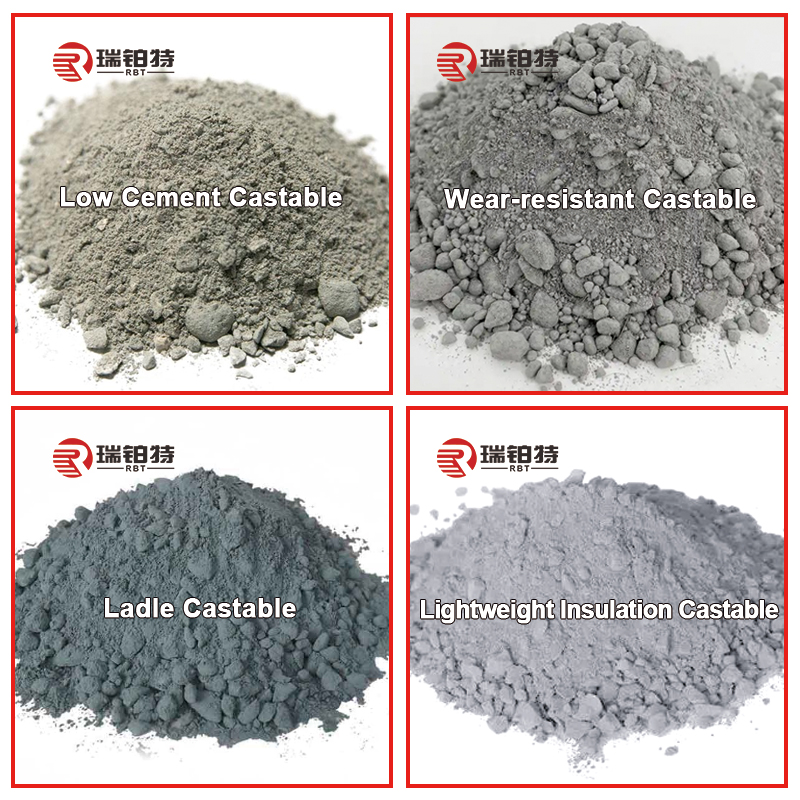

5. Low-cement castables: refers to castables with low cement content, which is generally about 5%, and some are even reduced to 1% to 2%. Low-cement castables use ultra-fine particles not exceeding 1μm, and their thermal shock resistance, slag resistance and erosion resistance are significantly improved. Low-cement castables are suitable for linings of various heat treatment furnaces, heating furnaces, vertical kilns, rotary kilns, electric furnace covers, blast furnace tapping holes, etc.; self-flowing low-cement castables are suitable for integral spray gun linings for spray metallurgy, high-temperature wear-resistant linings for petrochemical catalytic cracking reactors, and outer linings of heating furnace water cooling pipes.

6. Wear-resistant refractory castables: The main components of wear-resistant refractory castables include refractory aggregates, powders, additives and binders. Wear-resistant refractory castables are a type of amorphous refractory material widely used in metallurgy, petrochemicals, building materials, power and other industries. This material has the advantages of high temperature resistance, wear resistance, and erosion resistance. It is used to repair and protect the lining of high-temperature equipment such as furnaces and boilers to increase the service life of the equipment.

7. Ladle castable: Ladle castable is an amorphous refractory castable made of high-quality high-alumina bauxite clinker and silicon carbide as the main materials, with pure aluminate cement binder, dispersant, shrinkage-proof agent, coagulant, explosion-proof fiber and other additives. Because it has a good effect in the working layer of the ladle, it is also called aluminum silicon carbide castable.

8. Lightweight insulating refractory castable: Lightweight insulating refractory castable is a refractory castable with light weight, high strength and excellent thermal insulation performance. It is mainly composed of lightweight aggregates (such as perlite, vermiculite, etc.), high-temperature stable materials, binders and additives. It is widely used in various high-temperature industrial equipment, such as industrial furnaces, heat treatment furnaces, steel furnaces, glass melting furnaces, etc., to improve the energy utilization efficiency of equipment and reduce energy consumption.

9. Corundum castable: With its excellent performance, corundum castable has become an ideal choice for key parts of thermal kilns. The characteristics of corundum castable are high strength, high load softening temperature and good slag resistance, etc. The general use temperature is 1500-1800℃.

10. Magnesium castable: Mainly used in high-temperature thermal equipment, it has excellent resistance to alkaline slag corrosion, low oxygen potential index and no pollution to molten steel. Therefore, it has a wide range of application prospects in the metallurgical industry, especially in the production of clean steel and the building materials industry.

11. Clay castable: The main components are clay clinker and combined clay, with good thermal stability and certain refractoriness, and the price is relatively low. It is often used in the lining of general industrial kilns, such as heating furnaces, annealing furnaces, boilers, etc. It can withstand a certain temperature of heat load and play a role in heat insulation and protection of the furnace body.

12. Dry castables: Dry castables are mainly composed of refractory aggregates, powders, binders and water. Common ingredients include clay clinker, tertiary alumina clinker, ultrafine powder, CA-50 cement, dispersants and siliceous or feldspar impermeable agents.

Dry castables can be divided into many types according to their uses and ingredients. For example, dry impermeable castables are mainly used in aluminum electrolytic cells, which can effectively prevent the penetration of electrolytes and extend the service life of the cells. In addition, dry refractory castables are suitable for hardware, smelting, chemical industry, non-ferrous metals and other industries, especially in the steel industry, such as rotary kiln front kiln mouth, disintegration furnace, kiln head cover and other parts.

Post time: May-26-2025