In industries ranging from manufacturing to construction, and energy to agriculture, effective thermal insulation is not just a luxury—it`s a necessity. It cuts energy costs, protects critical equipment, and ensures safe, efficient operations. Clay insulation bricks stand out as a trusted, cost-effective solution worldwide, offering exceptional heat retention, long-lasting durability, and unmatched adaptability to diverse operational needs. Let`s explore their key applications and how they can add value to your projects.

1. Industrial Kilns & Furnaces: Secure High-Temperature Performance

Industrial kilns and furnaces (used in ceramic production, metal smelting, and glass manufacturing) operate at intense temperatures—making reliable insulation essential for maintaining stability and minimizing heat loss

Clay insulation bricks are engineered to excel in these harsh environments:

They line kiln/furnace walls and ceilings, creating a tight thermal barrier that traps heat inside. This reduces fuel usage by limiting heat escape, translating to significant long-term cost savings on energy.

Their strong thermal shock resistance prevents cracking or deterioration, even when kilns/furnaces undergo frequent heating and cooling cycles—a common challenge in industrial settings.

Designed to withstand temperatures from 800°C to 1,200°C, they align perfectly with the needs of most medium-temperature industrial heating equipment.

2. Building Construction: Boost Energy Efficiency & Indoor Comfort

For commercial buildings, residential properties, and public infrastructure, energy efficiency and occupant comfort are top priorities. Clay insulation bricks address both needs effectively:

Installed in exterior walls, roof insulation, or basement linings, they reduce heat transfer between indoor and outdoor spaces. This lowers reliance on heating systems in winter and air conditioning in summer, slashing energy bills for property owners.

Unlike synthetic insulation materials, clay insulation bricks are non-toxic, fire-resistant, and breathable. They regulate indoor humidity, reducing mold growth and creating a healthier living or working environment.

Suitable for new construction and retrofits (e.g., upgrading older buildings to meet modern energy codes), they integrate seamlessly with traditional and contemporary architectural designs.

3. Power & Energy Facilities: Protect Equipment & Ensure Reliability

Power plants (thermal, waste-to-energy, biomass) and energy storage systems depend on insulation to safeguard sensitive equipment and maintain consistent performance. Clay insulation bricks are a dependable choice here:

They insulate pipes, boilers, and heat exchangers in power plants, preventing heat loss from high-temperature fluids or gases. This keeps equipment operating at peak efficiency, reduces energy waste, and extends service life.

In thermal energy storage systems, they retain stored heat for extended periods, ensuring a steady energy supply when demand spikes.

Their resistance to corrosion and chemical exposure (common in industrial energy environments) makes them more durable than many alternatives, lowering maintenance costs over time.

4. Agricultural & Horticultural Settings: Create Controlled Environments

Agriculture and horticulture rely on stable temperatures to maximize crop yields and protect livestock. Clay insulation bricks support these goals reliably:

Used in greenhouse construction, they maintain consistent internal temperatures—keeping spaces warm in cold weather and cool in heat—creating optimal growing conditions for vegetables, flowers, and exotic plants.

For livestock shelters (poultry farms, dairy barns), they insulate walls and roofs to keep animals comfortable, reducing stress and improving productivity.

Their durability withstands moisture and temperature fluctuations in agricultural settings, ensuring long-term performance without degradation.

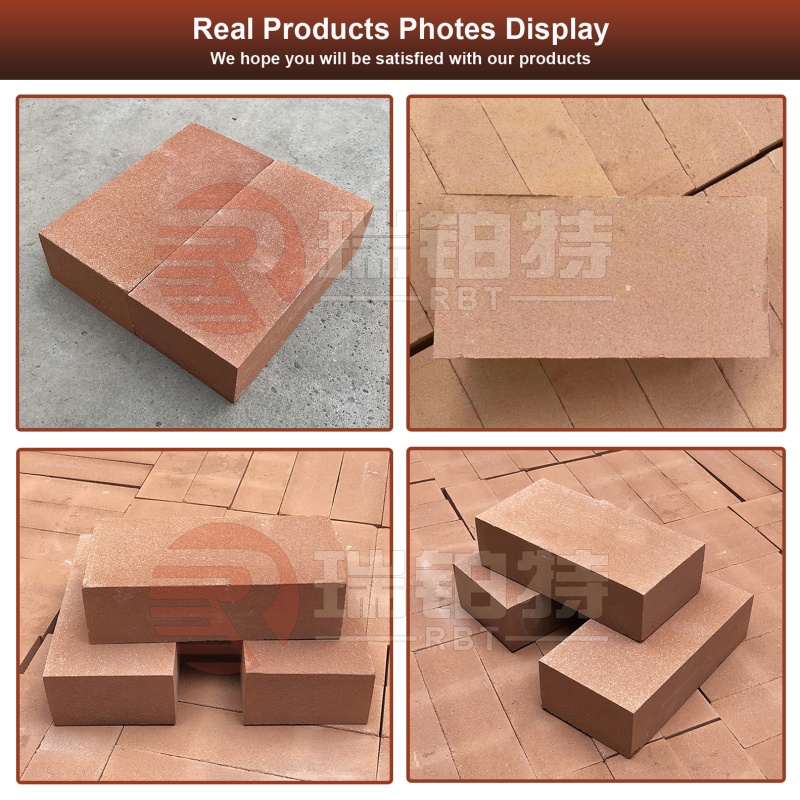

Why Choose Our Clay Insulation Bricks?

Our clay insulation bricks are crafted from high-quality natural clay and manufactured using advanced processes, guaranteeing consistent performance and reliability. We offer customizable sizes and specifications to fit your unique project requirements—whether you’re building a large industrial furnace, a residential complex, or an agricultural greenhouse. Additionally, our products meet global industry standards for safety and sustainability, helping you comply with regulations while reducing your carbon footprint.

Ready to upgrade your thermal insulation with clay insulation bricks? Contact us today to discuss your project, request a quote, or learn more about how our solutions can support your goals.

Post time: Sep-26-2025