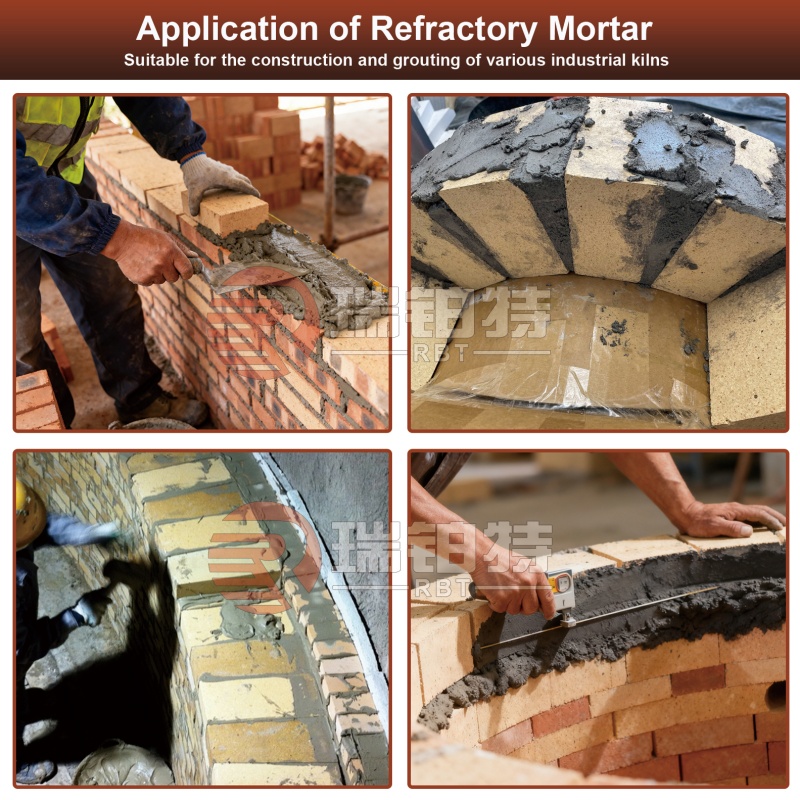

When it comes to high-temperature environments—from industrial furnaces to residential fireplaces—one material stands out as the backbone of structural integrity: clay refractory mortar. Designed to withstand extreme heat, chemical erosion, and thermal shock, this specialized mortar is far more than just a “glue” for refractory bricks. It`s a critical component that ensures safety, efficiency, and longevity in applications where ordinary mortars would crumble. Whether you`re in manufacturing, construction, or DIY home improvement, understanding the uses and benefits of clay refractory mortar can transform your high-temperature projects.

First and foremost, industrial furnaces and kilns are the primary playground for clay refractory mortar. In steel mills, glass factories, cement plants, and ceramic production facilities, furnaces operate at temperatures exceeding 1,000°C (1,832°F) for hours or even days on end. Ordinary Portland cement mortar melts or decomposes at such extremes, leading to structural failure, leaks, and costly downtime. Clay refractory mortar, however, is formulated with high-purity clay, silica, and other refractory aggregates that retain their bond strength and shape at these intense temperatures. It seals the gaps between refractory bricks, preventing heat loss that can reduce energy efficiency by up to 30%. For industrial operators, this translates to lower energy bills, fewer maintenance interruptions, and compliance with strict safety standards.

Beyond heavy industry, clay refractory mortar is a staple in commercial and residential heating systems. Fireplaces, wood-burning stoves, and chimney liners rely on it to create a secure, heat-resistant barrier. Imagine lighting a cozy fire in your living room only to have the mortar holding your fireplace bricks together crack and release toxic fumes—this is the risk of using non-refractory mortar. Clay refractory mortar not only withstands the repeated heating and cooling cycles of residential fireplaces but also resists the corrosive byproducts of burning wood or coal. It`s easy to mix and apply, making it a top choice for professional masons and DIY enthusiasts alike. Homeowners investing in a new fireplace or renovating an old one will find that using clay refractory mortar ensures their heating feature lasts for decades without compromising safety.

Another key application is petrochemical and metallurgical processes. Refineries, smelters, and foundries deal with not just high temperatures but also aggressive chemicals—acids, alkalis, and molten metals that would destroy conventional mortars. Clay refractory mortar`s chemical inertness makes it ideal for lining reaction vessels, crucibles, and exhaust systems. It forms a tight seal that prevents the leakage of hazardous materials, protecting workers and the environment. In aluminum smelting, for example, clay refractory mortar is used to line electrolytic cells, where it resists corrosion from molten aluminum and fluoride salts. This reliability is why it`s the preferred choice in industries where even the smallest failure can have catastrophic consequences.

Clay refractory mortar also plays a vital role in pizza ovens and commercial kitchens. Wood-fired pizza ovens operate at temperatures between 400°C and 500°C (752°F and 932°F), requiring a mortar that can handle intense heat without cracking or losing adhesion. Professional pizzerias and home chefs alike trust clay refractory mortar to build and repair these ovens, as it ensures consistent heat distribution and prevents smoke or heat from escaping. In commercial kitchens, it`s used to line grills, rotisseries, and other high-heat equipment, maintaining hygiene standards by preventing food particles from getting trapped in cracked mortar.

What sets clay refractory mortar apart from other refractory materials? Its versatility and cost-effectiveness. Unlike high-alumina or silica mortar, which are designed for ultra-high temperatures but come with a higher price tag, clay refractory mortar balances performance and affordability for most common high-temperature applications. It`s available in powder form, which can be mixed with water on-site to the desired consistency, reducing waste and transportation costs. Additionally, it has excellent workability—masons can easily shape and smooth it, ensuring a tight bond between bricks.

Choosing the right clay refractory mortar is crucial for your project`s success. Look for products that meet industry standards, such as ASTM C199, which specifies the requirements for refractory mortar. Consider the maximum temperature of your application, as some clay mortars are formulated for higher heat ranges than others. For industrial projects, opt for mortar with added additives that enhance thermal shock resistance and chemical stability. For residential use, a standard clay refractory mortar will suffice for most fireplaces and stoves.

In conclusion, clay refractory mortar is an indispensable material in any application that involves high temperatures. From industrial furnaces to home fireplaces, it provides the strength, heat resistance, and durability needed to keep structures safe and efficient. Its wide range of uses, cost-effectiveness, and ease of use make it a top choice for professionals and DIYers across industries. If you`re planning a high-temperature project, don`t settle for ordinary mortar—invest in clay refractory mortar and ensure your work stands the test of time.

Post time: Dec-01-2025