In the dynamic landscape of industrial innovation, finding the right materials to enhance efficiency, reduce energy consumption, and ensure long - term performance is crucial. Ceramic fiber modules have emerged as a game - changing solution, revolutionizing the way we approach thermal insulation and refractory applications.

What are Ceramic Fiber Modules?

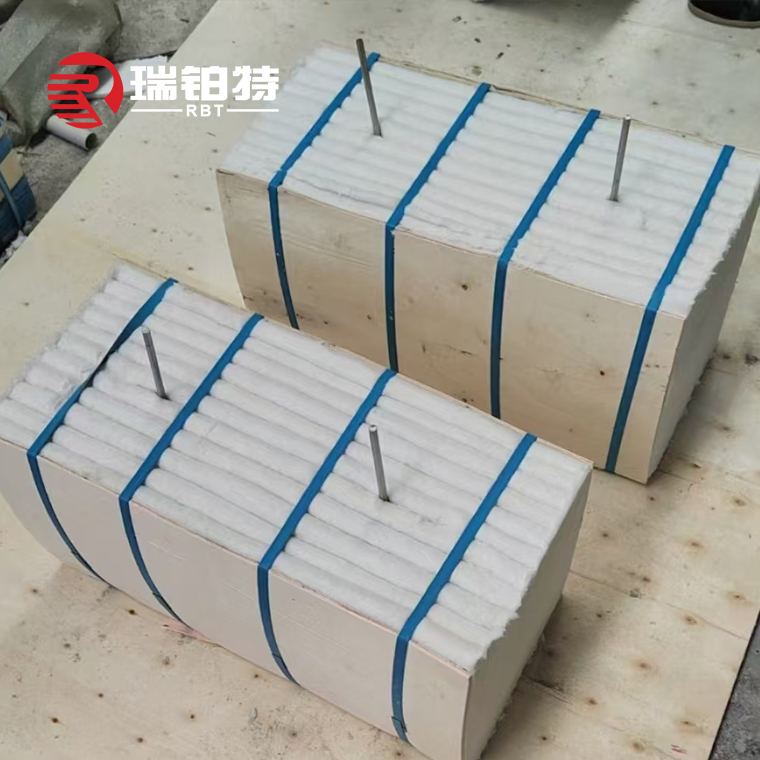

Ceramic fiber modules are advanced refractory products meticulously crafted from high - quality ceramic fiber blankets. These blankets are subjected to a specialized folding and compression process, followed by the pre - installation of anchorages. This results in a modular design that offers unparalleled convenience and performance. With the ability to be quickly and easily installed in a wide range of industrial furnaces and heating equipment, ceramic fiber modules are transforming the construction and operation of industrial kilns.

Unrivaled Advantages

1. Exceptional Thermal Insulation

Ceramic fiber modules are engineered to provide outstanding thermal insulation. Their low thermal conductivity effectively minimizes heat transfer, ensuring that your industrial processes operate at optimal temperatures. By reducing heat loss, these modules not only enhance energy efficiency but also contribute to significant cost savings over time. This makes them an ideal choice for industries where precise temperature control and energy conservation are of utmost importance.

2. High Temperature Resistance

With classification temperatures ranging from 1050℃ to 1600℃, ceramic fiber modules exhibit remarkable resistance to high temperatures. They can withstand extreme heat without compromising their structural integrity or insulating properties. This makes them suitable for use in some of the most demanding industrial environments, such as those found in the metallurgical, glass, and ceramics sectors. Whether it's a high - temperature furnace or a kiln operating at intense heat levels, ceramic fiber modules offer reliable performance and durability.

3. Quick and Easy Installation

The modular design of ceramic fiber modules is a game - changer when it comes to installation. Thanks to their pre - assembled structure, they can be directly assembled on - site, eliminating the need for complex and time - consuming traditional masonry work. This significantly reduces installation time, minimizing downtime for your industrial operations. In fact, compared to traditional refractory installation methods, ceramic fiber modules can boost installation efficiency by over 50%, allowing you to get your equipment up and running faster.

4. Excellent Sealing Performance

The unique folding structure of ceramic fiber modules results in a tight and seamless fit when installed. This not only reduces thermal bridging but also effectively prevents air leakage, enhancing the overall insulation performance of the furnace lining. The improved sealing also contributes to better energy efficiency and a more stable operating environment, ensuring that your industrial processes run smoothly and efficiently.

5. Customization Options

We understand that every industrial application is unique, which is why our ceramic fiber modules offer a high degree of customization. You can choose from a variety of sizes, densities, and anchoring methods to meet the specific requirements of your project. Whether you need a module for a small - scale furnace or a large - scale industrial kiln, we can provide a tailored solution that fits your needs perfectly.

6. Long Term Durability

Ceramic fiber modules are designed to withstand the test of time. Their resistance to mechanical stress, thermal shock, and chemical corrosion ensures a long service life. This means less frequent replacements and maintenance, reducing your overall operating costs. In addition, their ability to maintain their insulating properties over extended periods of use makes them a reliable choice for long - term industrial applications.

Versatile Applications

The versatility of ceramic fiber modules makes them suitable for a wide range of industrial applications:

Petrochemical Industry: They are extensively used in petrochemical furnace linings to provide efficient thermal insulation, ensuring the safe and smooth operation of petrochemical processes.

Metallurgical Industry: In the metallurgical sector, ceramic fiber modules play a crucial role in heat treatment furnaces, helping to achieve precise temperature control for high - quality metal processing.

Ceramics and Glass Industry: For kilns and furnaces in the ceramics and glass industries, these modules offer excellent heat retention, contributing to improved product quality and energy savings.

Heat Treatment Industry: Ceramic fiber modules are the go - to choice for heat treatment furnaces, providing the necessary thermal insulation for various heat treatment processes.

Other Industrial Furnaces: They are also widely used in other industrial furnaces, such as those in the power generation, automotive, and aerospace industries, to enhance energy efficiency and improve equipment performance.

Why Choose Our Ceramic Fiber Modules?

Quality Assurance: Our ceramic fiber modules are rigorously tested to ensure they meet the highest industry standards for performance and durability.

Technical Support: Our knowledgeable team is always on hand to offer technical advice and support, from product selection to installation and maintenance.

Competitive Pricing: We offer competitive pricing without compromising on quality, ensuring that you get the best value for your investment.

Don't miss out on the opportunity to enhance the performance of your industrial operations with our top - of - the - line ceramic fiber modules. Contact us today to learn more about our products and how they can benefit your business. Let us help you take your industrial processes to the next level!

Post time: Jun-27-2025