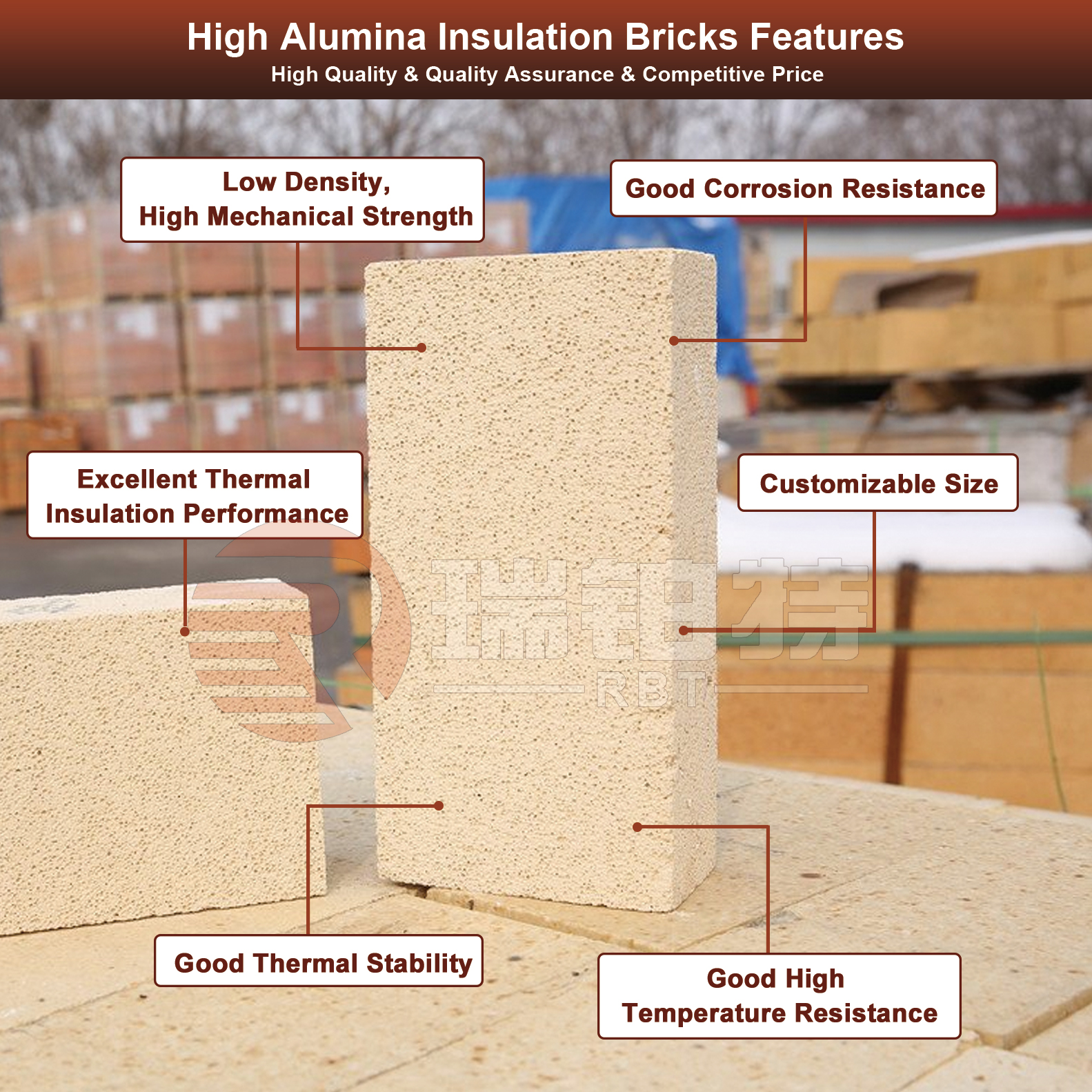

For high-temperature sectors like steel, cement, glass, and petrochemicals, reliable insulation isn’t just a cost saver—it’s a production lifeline. High Alumina Insulation Bricks (40%-75% Al₂O₃) stand out as the go-to solution, solving common pain points like heat loss, frequent replacements, and equipment damage that plague traditional materials. Their versatility across key industries makes them a top choice for 500+ global manufacturers.

Steel Industry: Boost Efficiency & Cut Costs

Steel production’s harshest environments—1500℃ blast furnaces, molten steel ladles, and precision heat treatment furnaces—demand tough insulation. These bricks line blast furnace shafts, slashing fuel use by 15%-20% (a South Korean mill saved $50k/year on coke). They protect ladles from thermal shock, ensuring safe molten steel transport and cutting maintenance by 50%. In tundishes, they reduce casting defects by 8%-12%, while in heat treatment furnaces, they maintain ≤5℃ temperature variation for consistent steel quality.

Cement & Glass: Stabilize High-Temp Processes

Cement rotary kilns cycle between cold starts and 1400℃ operation—stress that breaks weak insulation. High Alumina Bricks withstand these swings, stabilizing temperatures to lower energy use per ton of cement by 8%-12% (a German plant saved €28k/year on gas). For glass makers, they line 1450℃ melting furnaces, preventing bubbles or uneven thickness by keeping heat uniform. Their 5-8 year lifespan (5x longer than low-alumina bricks) means fewer shutdowns for replacements.

Petrochemical & Power: Resist Corrosion & Wear

Petrochemical plants face chemical vapor corrosion, while power facilities deal with fly ash abrasion—both ruin standard insulation. These bricks insulate catalytic crackers and high-temperature pipelines, resisting corrosion to extend equipment life. Their lightweight design (0.8-1.2 g/cm³) eases pipeline load, and their heat retention lowers surface temperatures for safer operations. A US petrochemical site cut pipeline insulation changes from 2x/year to 1x/6 years.

Why Choose Us?

We tailor bricks to your needs: adjust Al₂O₃ content (40% for mid-temp, 75% for ultra-high heat), size, and density. All meet ASTM/CE/JIS standards, ensuring global compliance. Get 2-3 free samples to test, and our engineers offer on-site assessments.

Email [info@sdrobert.cn] with your industry/equipment (e.g., “cement rotary kiln, 1400℃”) for a free proposal. Join manufacturers saving energy and reducing downtime—start today!

Post time: Oct-11-2025