In the field of high-temperature industries, the performance of materials directly determines the stability and efficiency of production. High alumina refractory bricks, as high-quality refractory materials mainly made from high-alumina bauxite, have become the ideal choice for numerous high-temperature industries with their outstanding performance, safeguarding the development of global metallurgy, building materials, chemical and other industries.

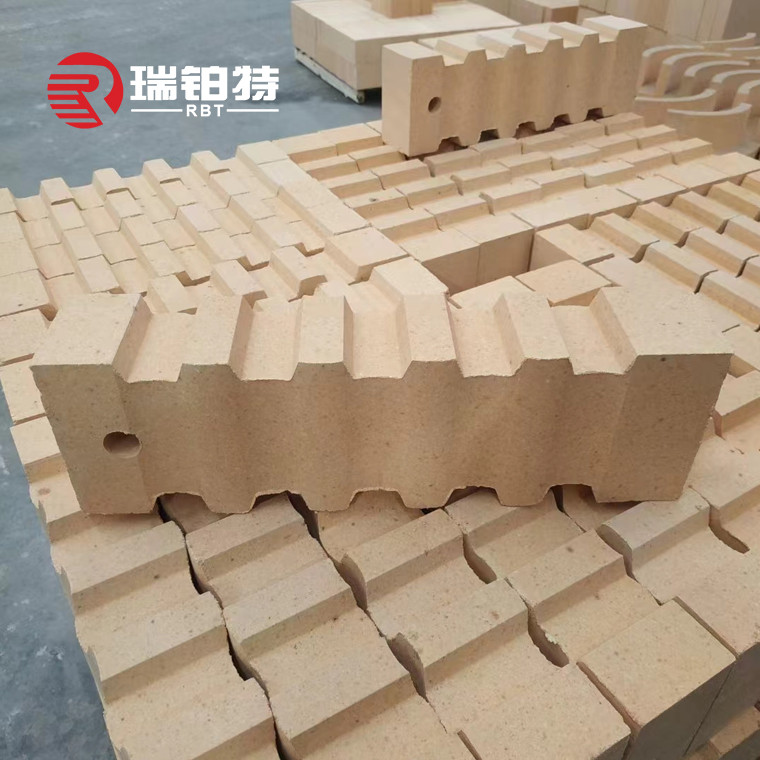

The core advantages of high alumina refractory bricks stem from their unique composition and manufacturing process. These bricks are made from high-alumina bauxite clinker with an alumina content of not less than 48% as the aggregate, combined with binders in different proportions, and then formed, dried, and fired at high temperatures. High alumina refractory bricks have excellent refractoriness, capable of withstanding high temperatures ranging from 1770°C to 1790°C. Even in extreme high-temperature environments, they can maintain structural integrity, effectively resisting the erosion of high temperatures on equipment. Their good load softening temperature ensures that they are not prone to deformation and collapse under certain pressure and high temperatures, providing reliable guarantees for the stable operation of high-temperature equipment. In addition, high alumina refractory bricks have excellent thermal shock resistance, which allows them to maintain stable performance during frequent temperature changes, reducing cracking and spalling caused by thermal stress and extending their service life. They also have strong resistance to various chemical substances. Whether it is the slag in the metallurgical process or the corrosive gases in chemical production, it is difficult to cause serious damage to them.

High alumina refractory bricks have a wide range of applications. In the metallurgical industry, they are key materials for the linings of steelmaking furnaces, ironmaking furnaces, and reheating furnaces. They can effectively resist the erosion of high-temperature molten steel and slag, ensuring the smooth progress of the smelting process and improving the service life of equipment and production efficiency. In the building materials industry, high alumina refractory bricks are commonly used in equipment such as cement rotary kilns and glass melting furnaces. In environments with high temperatures, high-speed airflow scouring, and material abrasion, they can still maintain good performance, supporting the stable operation of building materials production. In the chemical industry, high alumina refractory bricks play an important role in high-temperature reaction furnaces and gasifiers. With their excellent chemical corrosion resistance, they ensure the safety and efficiency of the chemical production process.

We are equipped with advanced production equipment and a strict quality control system. Every link, from raw material procurement to finished product delivery, is carefully monitored. By adopting internationally leading production processes, we ensure that the quality of high alumina refractory bricks meets international standards. At the same time, we also provide professional technical support and comprehensive after-sales services. According to the different needs of customers, we offer personalized solutions to ensure that high alumina refractory bricks can perform optimally in practical applications.

Choosing our high alumina refractory bricks means choosing quality and reliability. Whether you need large-scale procurement or professional refractory material solutions, we can meet your requirements. We warmly welcome customers from all over the world to contact us and work together to create a bright future for the high-temperature industry!

Post time: Jul-02-2025