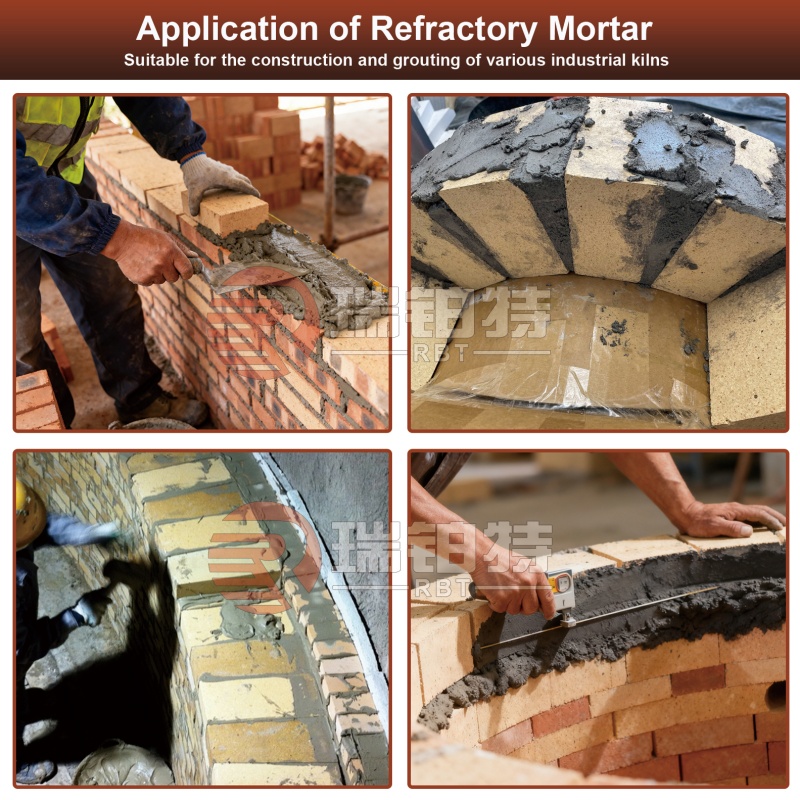

In industries where extreme heat is a constant challenge, the choice of refractory materials can make or break operational efficiency, safety, and cost-effectiveness. High alumina refractory mortar stands out as a cornerstone material, engineered to withstand relentless high temperatures, chemical erosion, and mechanical wear. Whether you`re in metallurgy, ceramics, glass manufacturing, or any sector requiring heat-resistant bonding, this specialized mortar delivers unparalleled performance that generic alternatives simply can`t match. Let`s explore why high alumina refractory mortar is the top choice for critical high-temperature applications worldwide.

First and foremost, high alumina refractory mortar excels in metallurgical applications, a sector where temperatures often soar above 1500°C. In steel mills, it is widely used for bonding refractory bricks in blast furnaces, ladles, tundishes, and electric arc furnaces. The high alumina content (typically 70% to 90%) grants it exceptional refractoriness, preventing melting or deformation even under the intense heat of molten steel. Additionally, it resists corrosion from molten slag, metal oxides, and other aggressive substances common in steel production. This durability reduces downtime caused by refractory failures, ensuring continuous operation and lowering maintenance costs for steel manufacturers.

The ceramics and glass industries also rely heavily on high alumina refractory mortar. Ceramic kilns, used for firing pottery, tiles, and advanced ceramics, operate at temperatures between 1200°C and 1800°C. High alumina mortar provides a strong, heat-stable bond for refractory linings in these kilns, maintaining structural integrity even during repeated heating and cooling cycles. For glass melting furnaces, where temperatures exceed 1600°C, the mortar`s resistance to thermal shock is crucial. It prevents cracks and spalling caused by rapid temperature fluctuations, extending the lifespan of furnace linings and ensuring consistent glass quality. Unlike low-alumina mortars, it doesn`t react with glass melts, avoiding contamination that could ruin batches of glass products.

Another key application lies in petrochemical and thermal power plants. In boilers, incinerators, and reformers, high alumina refractory mortar bonds refractory components that face high temperatures, flue gases, and chemical attack from fuels and by-products. In coal-fired power plants, it withstands the abrasive nature of fly ash and the corrosive effects of sulfur oxides. In petrochemical crackers and reformers, it resists degradation from hydrocarbons and high-temperature steam, ensuring safe and efficient energy production. Its excellent adhesion properties also make it ideal for repairing damaged refractory linings, minimizing downtime and extending the service life of critical equipment.

Beyond these core industries, high alumina refractory mortar finds use in waste incineration plants, where it handles the high temperatures and corrosive gases produced by burning municipal and industrial waste. It is also essential in foundries for lining molds and crucibles used in casting metals. Its versatility, combined with its superior heat resistance and durability, makes it a universal solution for any application requiring reliable bonding in extreme thermal environments.

When selecting high alumina refractory mortar, it`s important to choose a high-quality product that meets industry standards. Look for mortar with consistent particle size distribution, strong adhesion, and excellent thermal shock resistance. Our high alumina refractory mortar is manufactured using premium raw materials and advanced processing techniques, ensuring it delivers exceptional performance in the most demanding applications. Whether you need to line a large steel furnace, repair a ceramic kiln, or maintain a power plant boiler, our mortar provides the reliability and longevity you need to keep your operations running smoothly.

Don`t compromise on performance when it comes to high-temperature applications. Choose high alumina refractory mortar for superior heat resistance, corrosion resistance, and durability. Contact us today to learn more about our products and how they can enhance your operational efficiency and reduce maintenance costs.

Post time: Dec-03-2025