In high-temperature scenarios such as industrial heat preservation and kiln heat insulation, the quality of ceramic fiber blankets directly determines the operational safety of equipment and energy consumption costs. However, the quality of products on the market varies greatly. How to quickly and accurately judge the quality of ceramic fiber blankets? Master the following 3 core dimensions to easily avoid misunderstandings in purchasing.

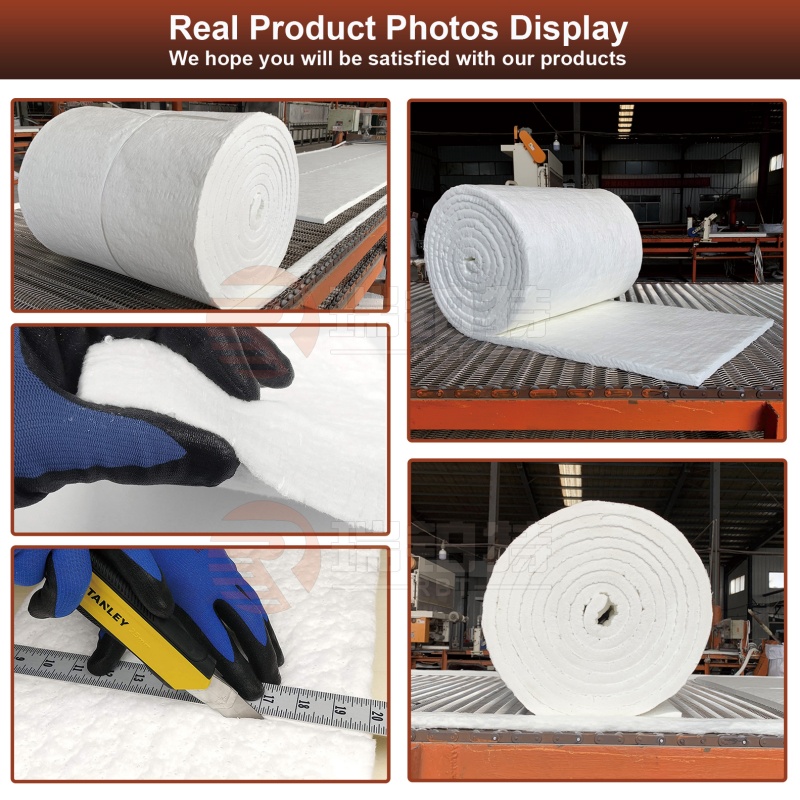

First, check the appearance and density—high-quality ceramic fiber blankets are "good products at first sight". A good product has a flat and uniform surface, with no obvious bulges, cracks or impurity spots, and the fiber distribution is fine without agglomeration. When touched by hand, it feels soft and elastic, and is not easy to shed residues or break. At the same time, you can compare the density through simple weighing—for products of the same thickness, those with a qualified density (usually 96-128kg/m³, depending on the application scenario) are more durable and have more stable thermal insulation performance. If the product feels too light, too thin or has loose fibers, it is likely to be a shoddy product with cut corners, which is prone to deformation and falling off after long-term use.

Second, test the key performance and verify the authenticity with "practical methods". High-temperature resistance is a core indicator. High-quality ceramic fiber blankets can withstand high temperatures of 1000-1400℃ (corresponding to the product model). When purchasing, you can ask the supplier to provide a sample and briefly bake the edge with a lighter. If there is no open flame, no pungent odor, and no obvious shrinkage or deformation after cooling, the high-temperature resistance is basically qualified. On the contrary, if there is smoke, melting or a plastic smell, it is an unqualified product. In addition, thermal insulation performance can be judged with the "hand temperature test" method: touch the blanket covering the surface of the heat source with your hand. If the outer temperature is low and there is no obvious heat penetration, it indicates good thermal insulation effect. At the same time, high-quality products dry easily after absorbing water, and their performance remains unchanged after drying, while shoddy products may suffer structural damage due to water absorption.

Finally, check the certifications and brands to avoid risks with "professional endorsements". Ceramic fiber blankets produced by regular manufacturers will have internationally recognized quality certifications, such as CE certification and ISO standard certification. Domestic products also need to have GB/T standard test reports. When purchasing, you can ask the supplier to show these certifications to avoid buying "three-no" (no manufacturer, no production date, no quality certificate) products. At the same time, prioritize brands with years of industry experience. Such enterprises not only have mature production processes, but also provide clear product parameters (such as composition, temperature resistance range, thermal conductivity) and after-sales service. If problems occur during subsequent use, they can be solved in a timely manner. However, products from small workshops often have vague parameters and no after-sales guarantee. Although they seem cheap, the later maintenance costs are actually higher.

Choosing high-quality ceramic fiber blankets can save more than 30% of energy consumption costs for industrial production and extend the service life of equipment. Master the methods of distinguishing quality from appearance, verifying performance, and ensuring reliability through certifications, so that every budget is spent on "key points" and a solid safety and heat insulation barrier is built for high-temperature scenarios.

Post time: Oct-27-2025