Anchor bricks are a special refractory material, mainly used for fixing and supporting the inner wall of the kiln to ensure the stability and durability of the kiln under high temperature and harsh working environment. Anchor bricks are fixed to the inner wall of the kiln by special anchors, which can resist high temperature, air flow scouring and material wear, thereby extending the service life of the kiln and maintaining the stability of the furnace environment.

Material and shape

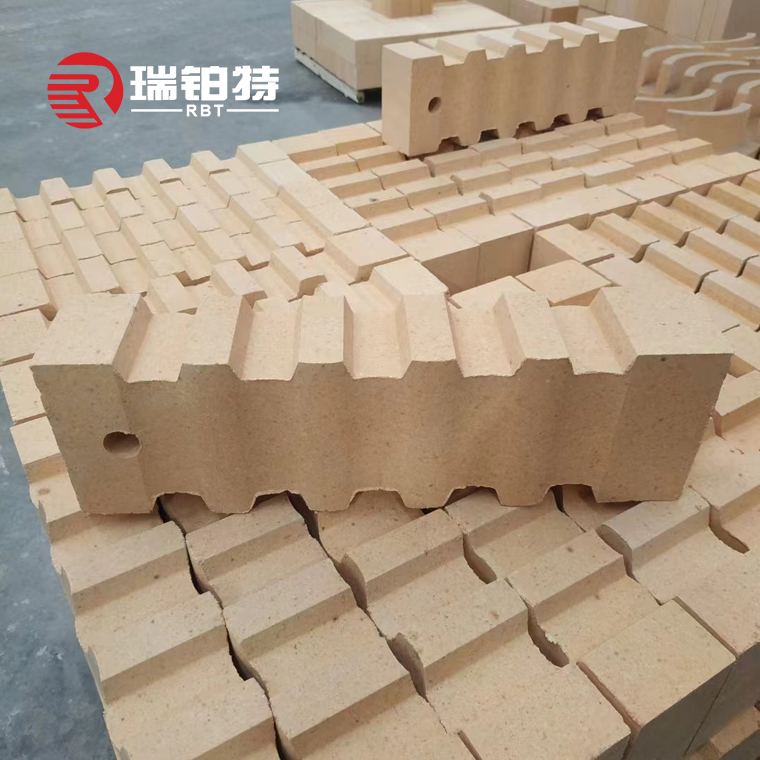

Anchor bricks are usually made of refractory raw materials such as high aluminum, magnesium, silicon or chromium, which have excellent stability and corrosion resistance at high temperatures. Its shape and size are customized according to the specific structure and process requirements of the kiln. Common shapes include rectangular, round and special shapes.

Application field

1. Casting industry: used for casting high-temperature alloys such as aluminum alloys, stainless steel, nickel-based alloys and titanium alloys.

2. Metallurgical industry: used for lining and fixing of high-temperature equipment such as continuous casting machine crystallizers, steelmaking arc furnaces, converters, hot blast furnaces, blast furnaces and desulfurization pools.

3. Cement industry: used for fixing and reinforcing equipment such as rotary kilns, coolers, preheaters, etc.

4. Petrochemical industry: used for fixing and reinforcing facilities such as pipelines and storage tanks in refineries.

5. Power industry: used for fixing and reinforcing equipment such as boilers in power plants, furnaces and tails of coal-fired and gas-fired thermal power stations.

Structural features

Anchor bricks are usually composed of hanging ends and anchor bodies, and have a column structure. The surface of the anchor body is provided with grooves and ribs distributed at intervals. The ribs play a role in reinforcement and pulling, improving the tensile and flexural strength and preventing fracture. In addition, anchor bricks also have the characteristics of high volume density, high compressive strength, strong spalling resistance, good thermal shock stability and strong impact resistance.

Post time: May-16-2025