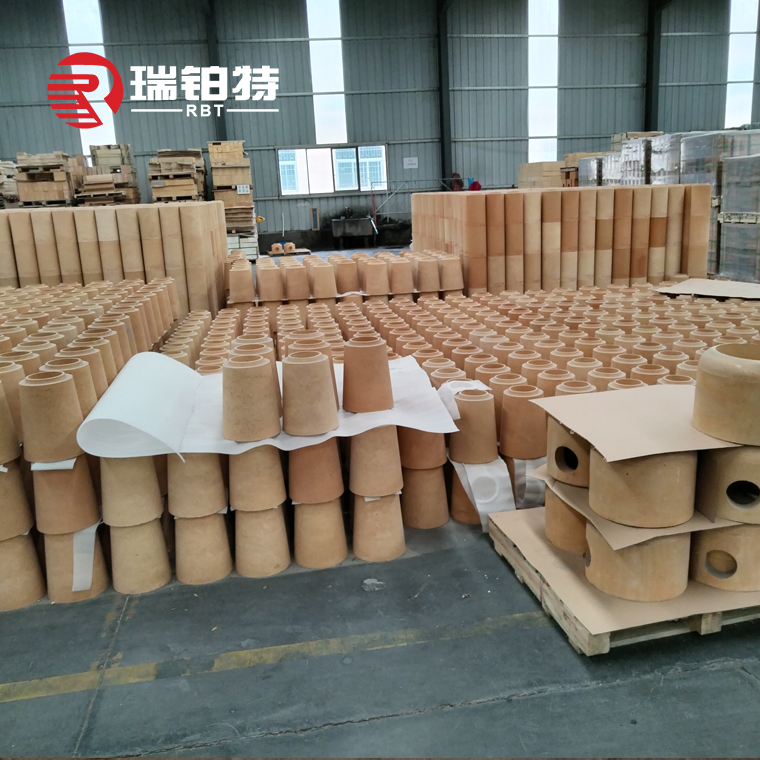

In the high-temperature furnace and precision continuous casting process of steel production, every detail is related to the quality and production efficiency of the final product. As the core refractory material to ensure the stable transmission of molten steel, the performance of flow steel bricks plays a decisive role. Choosing our flow steel bricks means choosing the efficiency and stability of steel production!

Excellent performance to cope with harsh production environment

Our flow steel bricks are made of advanced technology and high-quality raw materials, with three core advantages, which can perfectly cope with the harsh challenges in steel production.

Super strong thermal shock resistance: During the steel production process, the temperature of molten steel is as high as 1600℃ and the temperature changes frequently. Our flow steel bricks have been specially processed, with a tight internal structure and a low thermal expansion coefficient. They can withstand rapid temperature changes without cracking. After multiple thermal cycles, they still maintain an intact structure, building a reliable defense line for molten steel transmission.

Ultra-high wear resistance: Molten steel has a strong scouring force during transmission, and ordinary refractory materials are difficult to resist long-term erosion. Our flow steel bricks have high hardness, high density, smooth surface and thick wear-resistant layer, which can effectively reduce the erosion and wear of molten steel and slag. The service life is more than 30% higher than that of ordinary flow steel bricks, which greatly reduces the replacement frequency and reduces downtime.

Excellent corrosion resistance: The chemical substances in the steelmaking process are complex and seriously corrode refractory materials. Our flow steel bricks are made of high-purity raw materials and have excellent chemical stability. Whether it is acidic or alkaline slag, it can effectively resist corrosion, ensure that the purity of molten steel is not affected, and improve the quality of steel products.

Widely used to meet diversified production needs

Our flow steel bricks are suitable for multiple key links in steel production and provide reliable support for steel companies of different sizes.

Continuous casting machine tundish: During the continuous casting process, the molten steel in the tundish needs to be stably transferred to the crystallizer. Our flow steel bricks can accurately control the flow and direction of molten steel to ensure the continuous and stable continuous casting process and improve the quality and output of continuous casting billets.

Ladle sliding nozzle: As the key connection between the ladle and the tundish, the sliding nozzle has extremely high requirements for the sealing and durability of refractory materials. Our flow steel bricks have good sealing and wear resistance, which can effectively prevent molten steel leakage and ensure production safety.

Steel outlets of various steelmaking furnaces: Whether it is a converter, electric furnace or open furnace, the flow steel bricks at the steel outlet are subjected to huge high temperatures and pressures. With excellent performance, our flow steel bricks can withstand the impact of frequent steel tapping and extend the service life of the steel outlet.

Reasons for choosing us

Quality assurance: The products have passed ISO 9001 quality management system certification, and each flow steel brick has undergone strict quality inspection to ensure that the performance meets the standards.

Rich experience: With 15 years of experience in flow steel brick production, serving 500+ steel companies around the world, we have accumulated rich industry cases and practical experience.

Fast delivery: Modern production bases and efficient logistics systems ensure that orders are produced and shipped within 15 working days to meet your urgent production needs.

Click the [Get a Quote] button below and fill in your demand information. Our professional team will contact you within 6 hour to provide you with detailed product quotes and solutions. Let us work together to empower your steel production with high-quality flow steel bricks and create higher value!

Post time: Jun-09-2025