In the high-temperature industrial sector, the performance of kiln lining materials directly impacts production efficiency and product quality. As a representative of high-performance refractory materials, magnesia-alumina spinel bricks, with their excellent comprehensive properties, have become the ideal choice for industries such as steel, glass, and cement to resist high-temperature erosion and extend equipment lifespan, providing reliable support for high-temperature industrial production.

Leading the Industry with Exceptional Performance

Magnesia-alumina spinel bricks are synthesized from magnesia and aluminum oxide through special processes. Their unique crystal structure endows them with powerful performance advantages. These bricks exhibit outstanding high-temperature resistance, capable of withstanding extreme temperatures of up to 1800°C. Even in prolonged high-temperature environments, they maintain stable physical and chemical properties, effectively preventing damage to kiln linings caused by high temperatures.

Thermal shock resistance is a remarkable feature of magnesia-alumina spinel bricks. During the frequent heating and cooling cycles of kilns, ordinary refractory materials are prone to cracking and spalling due to thermal stress. However, with their low coefficient of thermal expansion and good toughness, magnesia-alumina spinel bricks can effectively mitigate thermal stress impacts, significantly reducing the risk of thermal shock damage, extending service life, and minimizing kiln downtime for maintenance.

Magnesia-alumina spinel bricks also perform exceptionally well in chemical erosion protection. They have excellent resistance to alkaline and acidic slag, as well as high-temperature gases, effectively preventing the penetration of harmful substances and safeguarding the structural safety of kilns. Whether in the highly alkaline environment of steel smelting or the high-temperature acidic atmosphere of glass production, they can stably fulfill their protective functions.

In-Depth Applications Across Multiple Industries

In the steel industry, magnesia-alumina spinel bricks are widely used in key areas of converters, ladles, and tundishes. During converter steelmaking, they can withstand the scouring and erosion of high-temperature molten steel and slag, ensuring the integrity of the converter lining. When used in ladles and tundishes, they can effectively reduce the reaction between molten steel and lining materials, improve the purity of molten steel, and enhance steel quality. After a large steel enterprise adopted magnesia-alumina spinel bricks, the service life of its ladles increased from an average of 60 heats to 120 heats, significantly reducing production costs.

In the glass manufacturing industry, magnesia-alumina spinel bricks are the preferred materials for key parts of glass kilns. In the hot spots and regenerators of glass melting furnaces, they can withstand the erosion of high-temperature glass melt and the scouring of high-temperature gases, maintaining the structural stability of the kiln, reducing kiln maintenance frequency, and improving the continuity and stability of glass production. After using magnesia-alumina spinel bricks, the overhaul cycle of glass kilns can be extended by 2 - 3 years, effectively enhancing the economic benefits of enterprises.

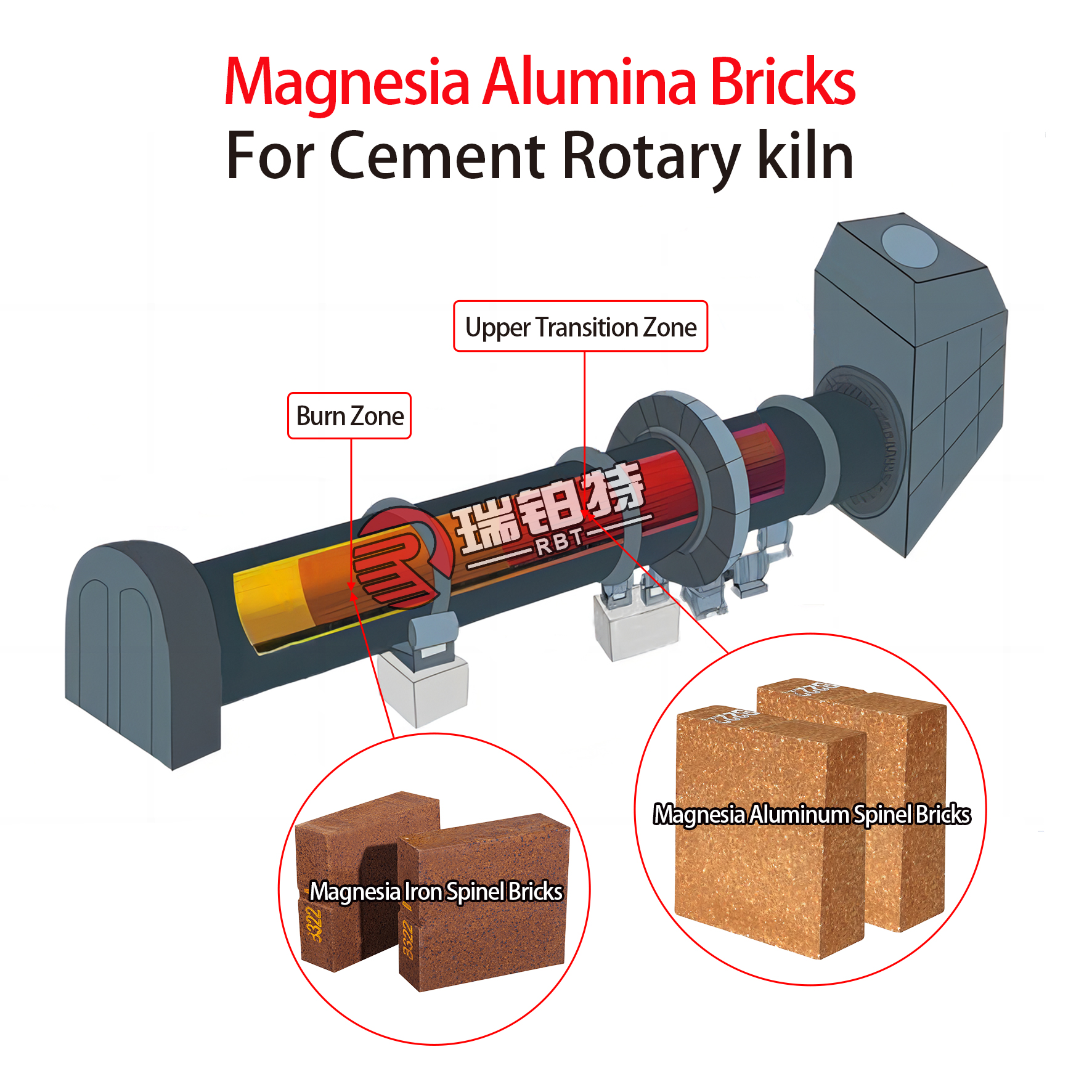

During cement production, the high-temperature environment of rotary kilns places strict requirements on refractory materials. With their high-temperature resistance, abrasion resistance, and good chemical stability, magnesia-alumina spinel bricks play a crucial role in the transition zone and burning zone of rotary kilns, ensuring the stable operation of the kiln body under high-temperature and high-load conditions and contributing to increased cement production and improved quality.

Professional Purchase Guide

When selecting magnesia-alumina spinel bricks, the following key points should be emphasized: First, pay attention to the chemical composition and mineral composition of the materials. High-purity magnesia and aluminum oxide raw materials can ensure the stable performance of the bricks. Second, focus on the physical performance indicators of the products, such as bulk density, apparent porosity, and cold crushing strength at room temperature. These indicators directly reflect the quality and durability of the bricks. Third, assess the production process and quality control system of suppliers. Choose suppliers with advanced production equipment, complete inspection processes, and rich industry experience to ensure reliable product quality. In addition, according to specific operating conditions, the dimensional accuracy and shape adaptability of the bricks also need to be considered to ensure smooth construction and installation.

With their outstanding performance and extensive applications, magnesia-alumina spinel bricks have become indispensable high-performance refractory materials in high-temperature industries. Whether it's improving production efficiency, reducing costs, or ensuring product quality, they can provide reliable solutions for enterprises. Contact us now to obtain professional product information and customized services, and let us safeguard your high-temperature industrial production!

Post time: Jun-23-2025