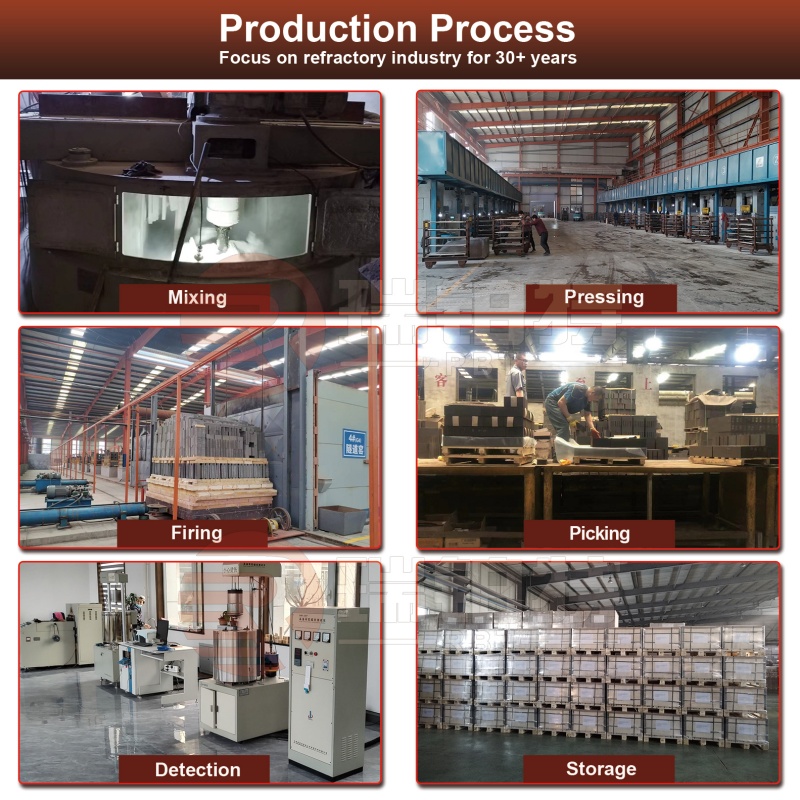

In the realm of high-temperature industrial furnaces (such as steelmaking converters, ladles, and blast furnaces), magnesium carbon bricks stand out as core refractory materials, thanks to their excellent resistance to corrosion, high-temperature stability, and thermal shock resistance. The production process of these bricks is a strict combination of technology and precision—each step directly determines the final product quality. Below, we take you through the complete manufacturing workflow of magnesium carbon bricks, revealing how we ensure every brick meets industrial-grade standards.

1. Raw Material Selection: The Foundation of High-Quality Magnesium Carbon Bricks

The quality of raw materials is the first line of defense for magnesium carbon brick performance. We adhere to strict selection criteria to ensure each component meets high standards:

High-Purity Magnesia Aggregate: We use fused magnesia or sintered magnesia with a MgO content of over 96%. This raw material provides the brick with strong high-temperature resistance and corrosion resistance, effectively withstanding the erosion of molten steel and slag in furnaces.

High-Grade Carbon Source: Natural flake graphite with a carbon content of 90%+ is selected. Its layered structure enhances the brick`s thermal shock resistance, reducing the risk of cracking due to rapid temperature changes during furnace operation.

Premium Binder: Phenolic resin (modified for high-temperature resistance) is used as the binder. It ensures strong bonding between magnesia and graphite, while avoiding volatilization or decomposition at high temperatures, which would affect the brick’s integrity.

Trace Additives: A small amount of antioxidants (such as aluminum powder, silicon powder) and sintering aids are added to prevent graphite oxidation and improve the brick`s density. All raw materials undergo 3 rounds of purity testing to eliminate impurities that could weaken performance.

2. Crushing and Granulating: Precise Particle Size Control for Uniform Structure

Uniform particle size distribution is key to ensuring the density and strength of magnesium carbon bricks. This stage follows strict technical parameters:

Crushing Process: First, large magnesia blocks and graphite are crushed into small particles using jaw crushers and impact crushers. The crushing speed is controlled at 20-30 rpm to avoid overheating and damage to the raw material structure.

Screening and Classification: Crushed materials are screened through multi-layer vibrating screens (with mesh sizes of 5mm, 2mm, and 0.074mm) to separate them into coarse aggregates (3-5mm), medium aggregates (1-2mm), fine aggregates (0.074-1mm), and ultrafine powders (<0.074mm). The particle size error is controlled within ±0.1mm.

Granule Homogenization: Different particle sizes are mixed in a high-speed mixer for 10-15 minutes at a speed of 800 rpm. This ensures that each batch of granules has consistent composition, laying the groundwork for uniform brick density.

3. Mixing and Kneading: Achieving Strong Bonding Between Components

The mixing and kneading stage determines the bonding strength between raw materials. We use advanced double-helix mixers and strictly control the process conditions:

Pre-Mixing of Dry Materials: Coarse, medium, and fine aggregates are first mixed dry for 5 minutes to ensure even distribution of each component. This step avoids local concentration of carbon or magnesia, which could cause performance differences.

Adding Binder and Kneading: Modified phenolic resin (heated to 40-50℃ for better fluidity) is added to the dry mixture, followed by 20-25 minutes of kneading. The mixer`s temperature is maintained at 55-65℃, and the pressure is controlled at 0.3-0.5 MPa—this ensures the binder fully wraps each particle, forming a stable "magnesia-graphite-binder" structure.

Consistency Testing: After kneading, the mixture`s consistency is tested every 10 minutes. The ideal consistency is 30-40 (measured by a standard consistency meter); if it is too dry or too wet, the binder dosage or kneading time is adjusted in real time.

4. Press Forming: High-Pressure Shaping for Density and Strength

Press forming is the step that gives magnesium carbon bricks their final shape and ensures high density. We use automatic hydraulic presses with precise pressure control:

Mold Preparation: Customized steel molds (according to customer requirements for brick size, such as 230×114×65mm or special-shaped sizes) are cleaned and coated with a release agent to prevent the mixture from sticking to the mold.

High-Pressure Pressing: The kneaded mixture is poured into the mold, and the hydraulic press applies a pressure of 30-50 MPa. The pressing speed is set to 5-8 mm/s (slow pressing to eliminate air bubbles) and held for 3-5 seconds. This process ensures the brick`s bulk density reaches 2.8-3.0 g/cm³, with a porosity of less than 8%.

Demolding and Inspection: After pressing, the bricks are demolded automatically and inspected for surface defects (such as cracks, uneven edges). Bricks with defects are immediately rejected to avoid entering the next process.

5. Heat Treatment (Curing): Enhancing Binder Bonding and Stability

Heat treatment (curing) strengthens the binder`s bonding effect and removes volatile substances from the bricks. We use tunnel kilns with precise temperature control:

Stepwise Heating: Bricks are placed in the tunnel kiln, and the temperature is raised stepwise:

20-80℃ (2 hours): Evaporate surface moisture;

80-150℃ (4 hours): Promote resin preliminary curing;

150-200℃ (6 hours): Complete resin cross-linking and curing;

200-220℃ (3 hours): Stabilize the brick structure.

The heating rate is controlled at 10-15℃/hour to prevent cracking due to thermal stress.

Volatile Substance Removal: During curing, volatile components (such as small-molecule resins) are discharged through the kiln`s exhaust system, ensuring the brick`s internal structure is dense and free of voids.

Cooling Process: After curing, the bricks are cooled to room temperature at a rate of 20℃/hour. Rapid cooling is avoided to prevent thermal shock damage.

6. Post-Processing and Quality Inspection: Ensuring Every Brick Meets Standards

The final stage of production focuses on precision processing and strict quality testing to ensure each magnesium carbon brick meets industrial application requirements:

Grinding and Trimming: Bricks with uneven edges are ground using CNC grinding machines, ensuring the dimensional error is within ±0.5mm. Special-shaped bricks (such as arc-shaped bricks for converters) are processed using 5-axis machining centers to match the furnace`s inner wall curve.

Comprehensive Quality Testing: Each batch of bricks undergoes 5 key tests:

Density and Porosity Test: Using the Archimedes method, ensure bulk density ≥2.8 g/cm³ and porosity ≤8%.

Compressive Strength Test: Test the brick`s compressive strength (≥25 MPa) using a universal testing machine.

Thermal Shock Resistance Test: After 10 cycles of heating (1100℃) and cooling (room temperature), check for cracks (no visible cracks allowed).

Corrosion Resistance Test: Simulate furnace conditions to test the brick`s resistance to molten slag erosion (erosion rate ≤0.5mm/h).

Chemical Composition Analysis: Use X-ray fluorescence spectrometry to verify MgO content (≥96%) and carbon content (8-12%).

Packaging and Storage: Qualified bricks are packaged in moisture-proof cartons or wooden pallets, with moisture-proof film wrapped around them to avoid moisture absorption during transportation. Each package is labeled with the batch number, production date, and quality inspection certificate for traceability.

Why Choose Our Magnesium Carbon Bricks?

Our strict production process (from raw material selection to post-processing) ensures that our magnesium carbon bricks have excellent performance in high-temperature industrial furnaces. Whether for steelmaking converters, ladles, or other high-temperature equipment, our products can:

Withstand temperatures up to 1800℃ without softening or deformation.

Resist molten steel and slag erosion, extending the furnace’s service life by 30%+.

Reduce maintenance frequency and production costs for customers.

We provide customized solutions according to your furnace type, size, and operating conditions. Contact us today to learn more about our magnesium carbon brick production process or to get a free quote!

Post time: Oct-29-2025