The steel industry stands as the backbone of global infrastructure, yet it operates in one of the harshest high-temperature environments on Earth. From the intense heat of iron smelting to the precision of steel casting, critical equipment like converters, electric arc furnaces, and blast furnaces face unrelenting stress: they must endure continuous exposure to temperatures that often exceed 1,600°C, paired with aggressive erosion from molten slag and scalding steel. This extreme conditions place unparalleled demands on refractory materials—the protective layers that shield equipment from damage—and among all options, magnesium-chromium bricks emerge as the ultimate, reliable solution.

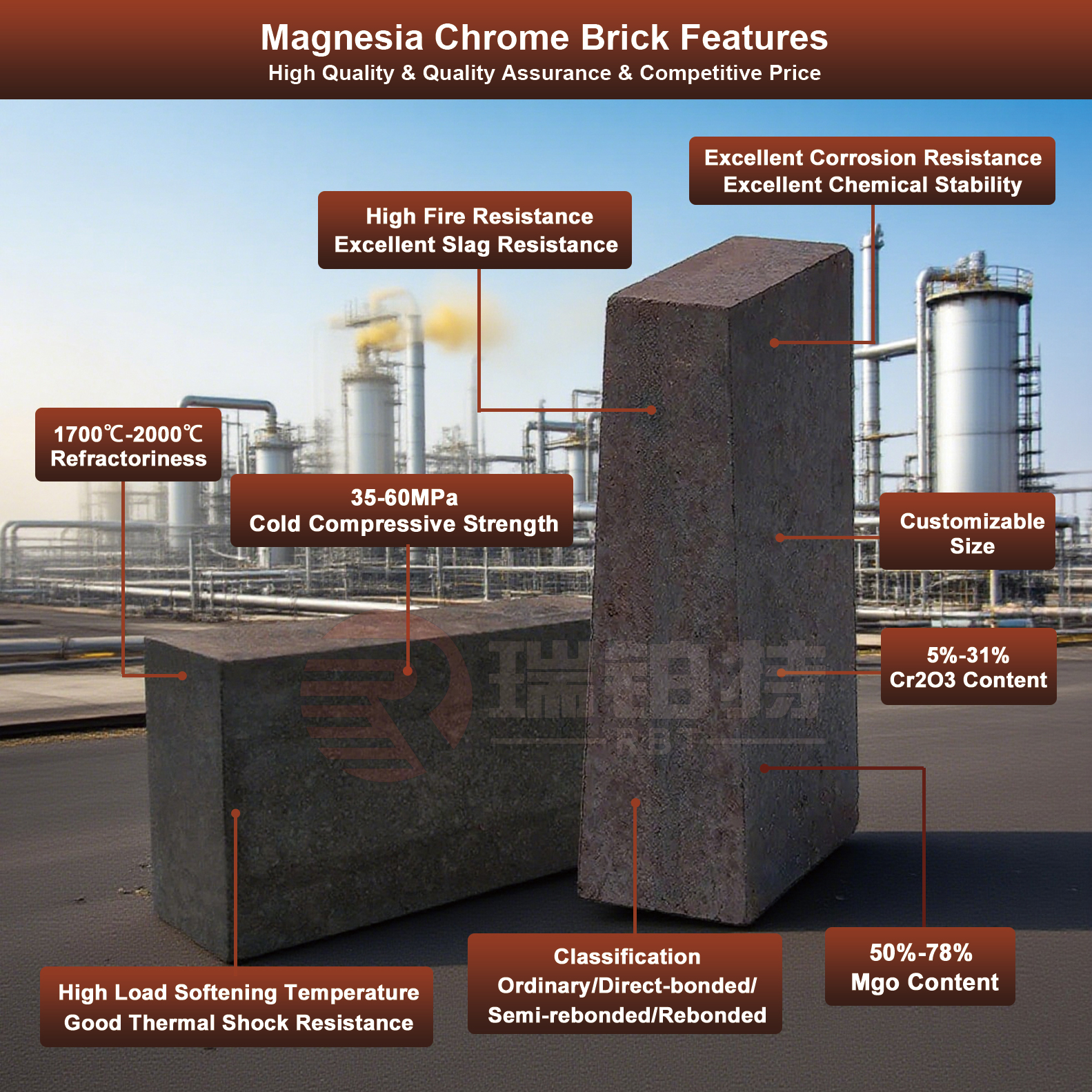

Magnesium-chromium bricks owe their unrivaled position in the steel industry to three core, unbeatable properties that address every major pain point of high-temperature steel production. First, their exceptional fire resistance is a game-changer for safety and efficiency: with a refractoriness rating well above 1,700°C, these bricks maintain their structural integrity even in the hottest cores of steelmaking furnaces. Unlike inferior refractory materials that may soften or melt under extreme heat, magnesium-chromium bricks eliminate the risk of sudden equipment failure, which could halt production lines and lead to costly delays. Second, their superior slag resistance directly tackles one of the steel industry’s biggest maintenance challenges. Composed of high-purity magnesium oxide and chromium oxide, the bricks form a dense, impermeable barrier that repels both alkaline and acidic slags—common byproducts of steel production that eat away at conventional linings. This resistance drastically extends furnace lining life by 30% or more compared to standard refractories, slashing frequent replacement costs and reducing unplanned downtime. Third, their excellent thermal shock stability ensures consistency during critical operational phases. When furnaces start up or shut down, temperatures can swing by hundreds of degrees in a short period—a stress that causes most bricks to crack or spall. Magnesium-chromium bricks, however, absorb these fluctuations effortlessly, keeping linings intact and production running smoothly without interruptions.

These standout properties make magnesium-chromium bricks indispensable across every key stage of steelmaking, from raw material processing to final casting. In converters and electric arc furnaces, where steel is melted and refined, the bricks line the inner walls, enduring direct scouring from churning molten steel and corrosive slag. This protection allows furnaces to operate at peak efficiency for longer stretches, boosting daily steel output. In ladles—the large vessels that transport molten steel from furnaces to casting machines— magnesium-chromium bricks act as a robust liner. They prevent heat loss that would compromise steel quality and block potential leakage, ensuring the molten metal reaches its next stage in perfect condition for downstream processing like rolling or forging. Even in blast furnaces, the heart of iron production, these bricks protect critical upper and lower zones from the combined attack of high-temperature gas (up to 2,000°C) and molten slag, sustaining long-term, stable operation that is vital for consistent iron supply.

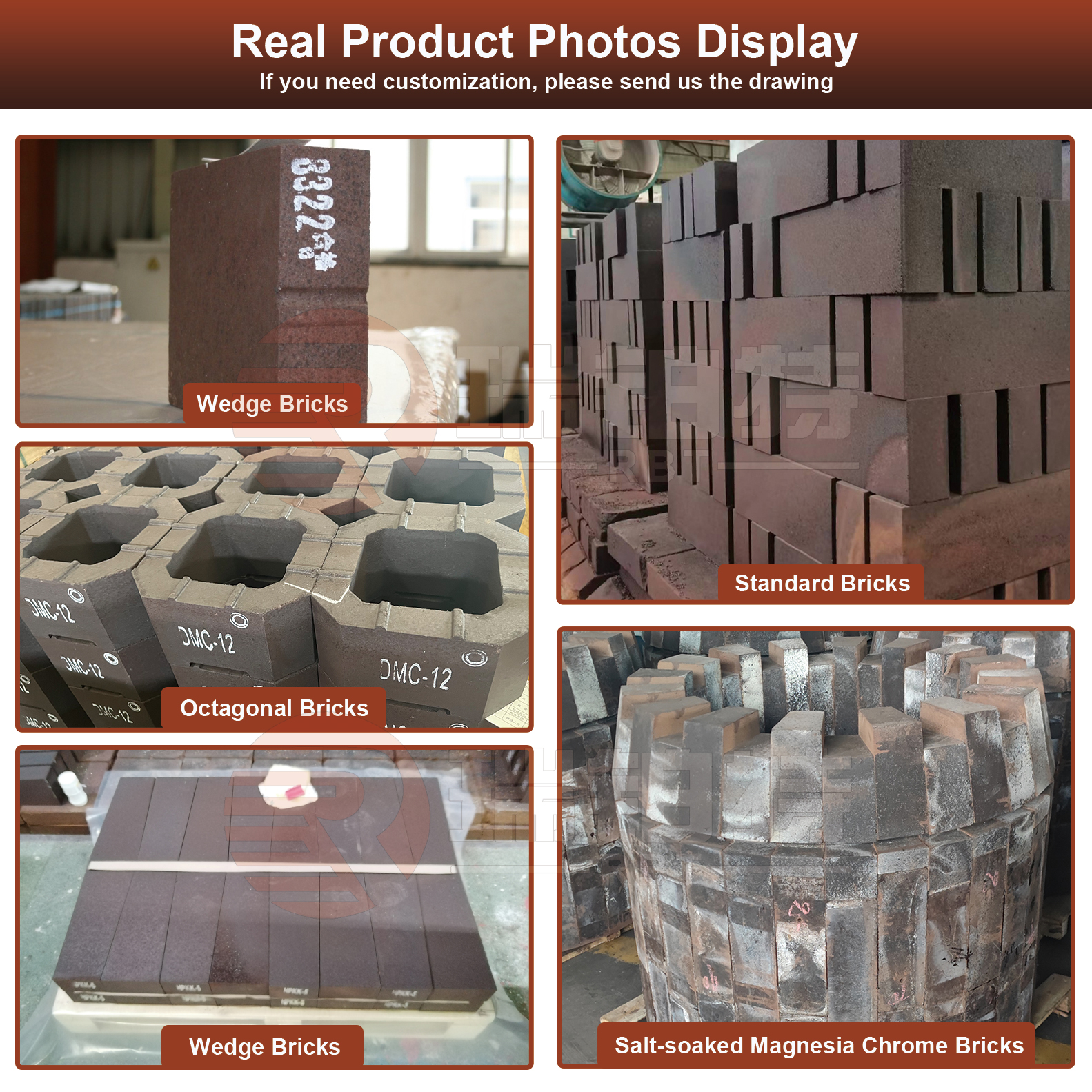

For steel manufacturers striving to boost productivity, cut operational costs, and maintain a competitive edge, choosing high-quality magnesium-chromium bricks is not just an option—it’s a necessity. Our magnesium-chromium bricks are engineered with strict quality controls, using premium raw materials that undergo rigorous testing to meet global industry standards. Trusted by leading steel plants across Asia, Europe, and North America, our products have a proven track record of delivering consistent performance, even in the most demanding production environments. Partner with us today, and let our industry-leading fire-resistant solution strengthen your steelmaking process, minimize downtime, and help you achieve sustainable, long-term growth.

Post time: Oct-22-2025