Thermocouples are the backbone of temperature monitoring in countless industrial processes—from metal smelting to chemical synthesis. Yet, their performance and lifespan depend entirely on one critical component: the protection tube. In harsh industrial environments, traditional thermocouple protection tubes (made of metal, alumina, or pure silicon carbide) often fail to withstand extreme heat, corrosive media, or abrasive particles. This leads to frequent thermocouple replacements, inaccurate temperature data, and costly production downtime.

If you`re tired of compromising on thermocouple reliability, Silicon Nitride Bonded Silicon Carbide (NSiC) Thermocouple Protection Tubes are the game-changing solution you need. Engineered to protect thermocouples in the most demanding conditions, NSiC tubes ensure consistent, accurate temperature sensing while maximizing the service life of your critical measurement equipment.

Why Silicon Nitride Bonded Silicon Carbide Stands Out for Thermocouple Protection

Thermocouple protection tubes require a unique balance of properties: heat resistance, corrosion resistance, mechanical strength, and thermal conductivity. NSiC excels in all these areas, outperforming traditional materials in every key metric:

1. Extreme Temperature Resistance for Uninterrupted Sensing

Thermocouples in industries like glass manufacturing or metal casting operate in temperatures exceeding 1,500°C. NSiC thermocouple protection tubes handle this with ease—boasting a continuous operating temperature of up to 1,600°C (2,912°F) and short-term resistance to 1,700°C (3,092°F). Unlike metal tubes that oxidize or melt, or alumina tubes that crack under thermal shock, NSiC maintains structural integrity even during rapid temperature fluctuations. This means your thermocouple stays protected, and your temperature data remains accurate—no matter how intense the heat.

2. Superior Corrosion Resistance to Defend Against Aggressive Media

Industrial processes often expose thermocouples to molten metals (aluminum, zinc, copper), acidic/alkaline solutions, or corrosive gases (sulfur dioxide, chlorine). NSiC`s dense, nitride-bonded structure creates an impenetrable barrier against these substances. Unlike pure silicon carbide tubes, which are prone to oxidation in moist high-temperature environments, NSiC`s unique composition enhances oxidation resistance—ensuring your thermocouple stays shielded from corrosion for years. This is critical for applications like chemical processing, waste incineration, and battery material synthesis.

3. Exceptional Mechanical Strength to Withstand Wear & Impact

Thermocouples in cement plants, power stations, or mineral processing facilities face constant threats: abrasive dust, flying particles, and mechanical impact. NSiC thermocouple protection tubes are built to resist these challenges, with a flexural strength of over 300 MPa and a Vickers hardness (HV10) of ≥ 1,800. This makes them 3–5 times more durable than traditional tubes, reducing the need for frequent replacements. For your operations, this translates to less downtime, lower maintenance costs, and more reliable thermocouple performance.

4. Optimal Thermal Conductivity for Fast, Accurate Readings

A thermocouple`s value lies in its ability to respond quickly to temperature changes. NSiC`s thermal conductivity (60–80 W/(m·K)) is far higher than that of alumina or metal tubes, enabling rapid heat transfer from the process to the thermocouple junction. This ensures your thermocouple delivers real-time, accurate data—critical for maintaining process control and product quality. Additionally, NSiC`s low thermal expansion coefficient (3.5–4.5 × 10⁻⁶/°C) minimizes thermal stress, preventing cracks that could compromise measurement accuracy.

5. Cost-Effective Longevity for Lower Total Ownership Costs

While NSiC thermocouple protection tubes may have a higher initial investment than traditional options, their long service life (2–5 years in harsh conditions) and minimal maintenance needs deliver significant long-term savings. By reducing thermocouple replacement frequency and production downtime, NSiC lowers your total cost of ownership (TCO) and boosts your return on investment (ROI). For industrial plants looking to optimize efficiency, this is a smart, future-proof choice.

Key Applications: Where NSiC Thermocouple Protection Tubes Deliver Results

NSiC thermocouple protection tubes are tailored to industries where thermocouple reliability is non-negotiable. Here are the top applications where they excel:

1. Metal Smelting & Casting

Use Case: Protecting thermocouples in molten aluminum, zinc, copper, and steel furnaces.

Benefit: Resists corrosion from molten metals and thermal shock during casting, ensuring accurate temperature control for consistent metal quality.

2. Glass & Ceramic Manufacturing

Use Case: Shielding thermocouples in glass melting furnaces, ceramic kilns, and enamel firing processes.

Benefit: Withstands 1,600°C+ temperatures and corrosive glass melts, keeping thermocouples functional for years—no frequent replacements.

3. Power Generation (Coal, Gas, Biomass)

Use Case: Protecting thermocouples in boiler flues, incinerators, and gas turbines.

Benefit: Resists abrasion from fly ash and corrosion from flue gases (SO₂, NOₓ), ensuring reliable flue gas temperature monitoring and reducing power plant maintenance.

4. Chemical & Petrochemical Processing

Use Case: Safeguarding thermocouples in reactors, distillation columns, and acid/alkaline storage tanks.

Benefit: Impervious to corrosive chemicals and high pressure, protecting thermocouples and ensuring safe, precise process temperature control.

5. Cement & Mineral Processing

Use Case: Shielding thermocouples in cement kilns, rotary dryers, and mineral ore smelters.

Benefit: Withstands heavy abrasion from dust and particles, and high temperatures, extending thermocouple life and cutting replacement costs.

6. Battery & New Energy Materials

Use Case: Protecting thermocouples in lithium-ion battery material sintering (cathode/anode production) and fuel cell manufacturing.

Benefit: Resists corrosive atmospheres and high temperatures, ensuring consistent temperature control for high-quality energy materials.

Why Choose Our NSiC Thermocouple Protection Tubes?

At Shandong Robert, we specialize in manufacturing high-performance Silicon Nitride Bonded Silicon Carbide Thermocouple Protection Tubes designed to meet the unique needs of industrial temperature measurement. Our products offer:

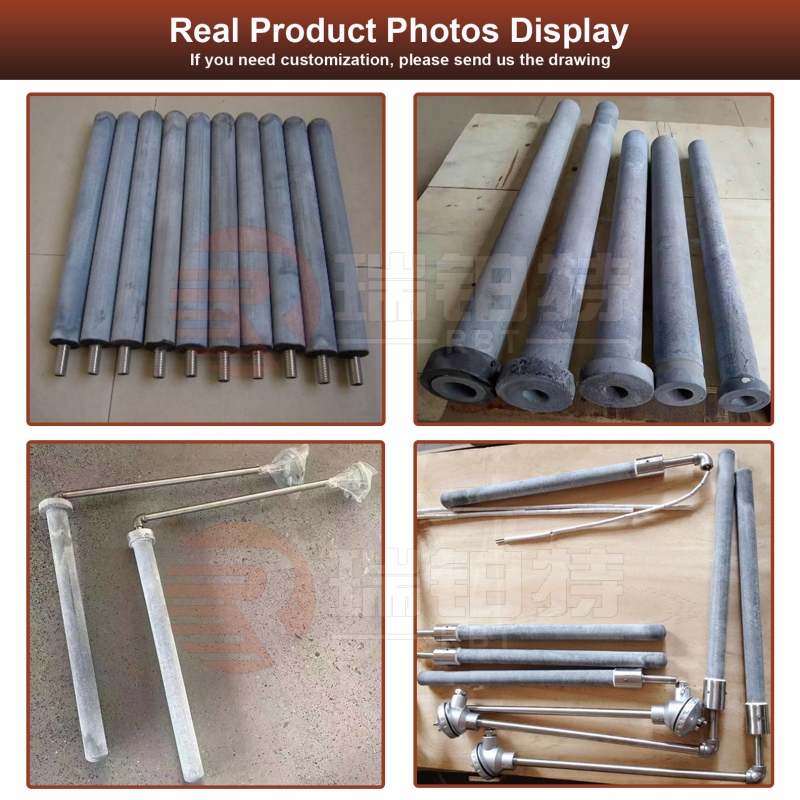

Perfect Thermocouple Compatibility: Available in sizes (OD 8–50 mm, length 100–1,800 mm) and configurations (straight, threaded, flanged) to fit all standard thermocouple types (K, J, R, S, B).

Precision Engineering: Each tube is manufactured with tight tolerances to ensure a secure fit, preventing media leakage and protecting your thermocouple.

Rigorous Quality Testing: Every tube undergoes strict testing for density, strength, corrosion resistance, and thermal performance.

Global Support: We offer fast delivery, technical consultation, and after-sales service to help you integrate our tubes seamlessly into your processes.

Ready to Protect Your Thermocouples & Optimize Your Processes?

Don`t let inferior protection tubes compromise your thermocouple performance or your bottom line. Upgrade to Silicon Nitride Bonded Silicon Carbide Thermocouple Protection Tubes and experience longer thermocouple life, more accurate temperature data, and lower maintenance costs.

Contact us today for a free sample, custom quote, or technical consultation. Let`s help you keep your industrial processes running smoothly—with the most reliable thermocouple protection on the market.

Post time: Sep-11-2025