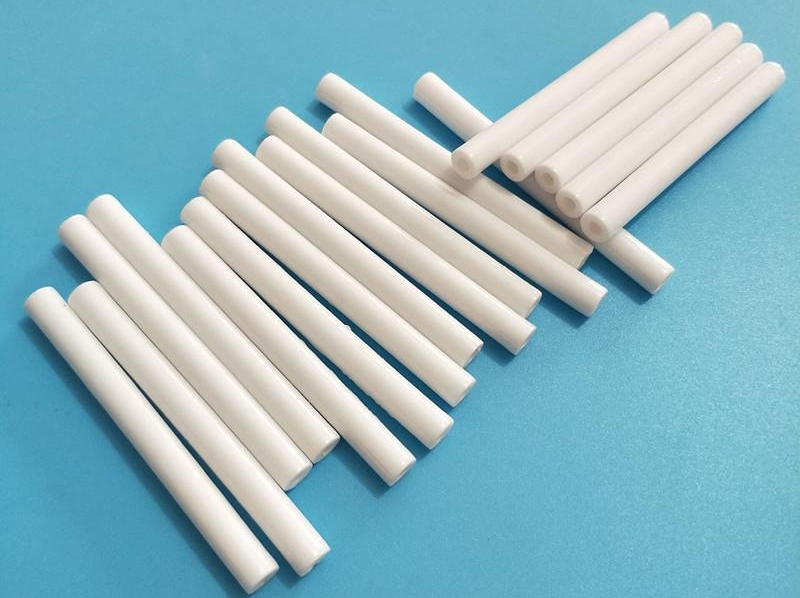

In the fast - paced evolution of modern industry, the demand for materials with superior performance has never been higher. Alumina ceramic tubes, with their unique physical and chemical properties, have emerged as the go - to choice for enhancing production efficiency and ensuring top - notch product quality across various sectors, driving a new wave of innovation in industrial applications.

I. Unparalleled Performance: The Industry Benchmark

1. Exceptional High - Temperature Resistance and Thermal Insulation

Alumina ceramic tubes can withstand extreme temperatures of over 1700°C. In high - temperature environments such as metallurgical furnaces and ceramic kilns, they maintain their structural and chemical integrity, resisting softening and deformation even under intense heat. Their excellent thermal insulation properties minimize heat loss, optimizing energy efficiency and safeguarding the safety of operators. For instance, in glass fiber production, these tubes ensure a stable temperature during the high - temperature transportation of glass melt, significantly enhancing product quality.

2. Outstanding Corrosion Resistance

With highly stable chemical properties, alumina ceramic tubes offer robust resistance against strong acids, alkalis, and corrosive chemical solutions. In the chemical and pharmaceutical industries, when transporting highly corrosive reagents like hydrochloric acid and sulfuric acid, or handling corrosive pharmaceutical raw materials, they remain chemically inert, eliminating leakage risks caused by corrosion and ensuring production safety and material purity. In pharmaceutical synthesis workshops, they reliably transport corrosive reaction solvents, maintaining integrity over long - term use and providing a solid guarantee for drug quality.

3. High Hardness and Minimal Wear

With a Mohs hardness of around 9, alumina ceramic tubes exhibit extremely low wear rates when exposed to high - hardness particles. In industries such as mining and cement, when conveying slurries laden with sand, ore, or cement particles, they effectively resist impact and abrasion, extending their service life significantly. Compared to ordinary metal pipes, the replacement cycle of alumina ceramic tubes can be multiplied, greatly reducing maintenance costs and downtime.

4. Superior Electrical Insulation

Alumina ceramic tubes are perfect electrical insulators with stable insulation performance. They can effectively block the flow of electric current in high - voltage and strong - electric - field environments. In the electronics and electrical manufacturing sectors, they are used to make packaging casings and insulating sleeves for electronic components, ensuring stable device operation, preventing malfunctions and safety hazards caused by electric leakage, and enabling electronics products to achieve higher performance and reliability.

II. Diverse Applications: Powering Industrial Upgrades

1. Chemical and Environmental Protection Sectors

In the chemical industry, alumina ceramic tubes are widely used in chemical raw material transportation and as linings for chemical reactors, ensuring efficient and safe production. In environmental protection, they play a vital role in treating industrial wastewater and exhaust gas. Their corrosion resistance and stability make them indispensable in processes such as acid - base neutralization and wastewater filtration, helping enterprises achieve green and sustainable development.

2. Energy and Power Industry

In the energy field, alumina ceramic tubes are suitable for new energy industries like solar photovoltaics and nuclear energy. For example, in solar thermal power generation systems, they serve as pipelines for high - temperature heat - transfer fluids; in nuclear power plants, they act as key components such as control rod sleeves, ensuring reactor safety. In the traditional power industry, they are used for high - temperature steam pipes and coal ash conveying pipes, improving power production stability and economic efficiency.

3. Electronics and Semiconductor Industry

During electronics and semiconductor manufacturing, alumina ceramic tubes, with their high purity, low impurity content, excellent electrical insulation, and thermal stability, are essential for critical processes like chip manufacturing and integrated circuit packaging. They are used to make wafer transfer tubes and gas - conveying pipelines, ensuring electronic components are produced in a clean and stable environment and boosting product yield.

4. Biomedical Field

Thanks to their excellent biocompatibility, non - toxicity, and lack of immune - triggering properties, alumina ceramic tubes are making waves in the biomedical field. They are used to fabricate artificial joints, dental restoration materials, and internal pipelines for medical devices, providing patients with safer and more durable medical solutions and advancing medical technology.

III. Choose Our Alumina Ceramic Tubes: Start Your Quality Journey

We specialize in the R & D and production of alumina ceramic tubes, equipped with advanced production processes and strict quality control systems. Every step, from raw material selection to product delivery, is rigorously inspected to ensure our products meet international leading standards. We offer customized services to meet diverse customer needs, covering pipe diameter, wall thickness, and special performance requirements. Choosing our alumina ceramic tubes means choosing efficiency, safety, and reliability, giving you a competitive edge in the market and starting your quality - upgrading journey.

Alumina ceramic tubes create value for enterprises in all industries with their outstanding performance. Contact us now to learn more about our products and get your exclusive solution!

Post time: Jun-12-2025