In the realm of high-temperature industrial operations, the demand for durable, heat-resistant materials is non-negotiable. Silicon Carbide (SiC) Bricks have emerged as a game-changer, offering unparalleled performance in extreme environments. Let’s explore their diverse applications and why they are the top choice for industries worldwide.

1. Metallurgical Industry

Silicon Carbide Bricks are widely used in metallurgical furnaces, including blast furnaces, electric arc furnaces, and ladle linings. Their exceptional thermal shock resistance and high melting point (over 2700°C) make them ideal for withstanding rapid temperature fluctuations during metal smelting and refining. They also reduce heat loss, improving energy efficiency and lowering operational costs.

2. Ceramic and Glass Manufacturing

In ceramic kilns and glass melting furnaces, SiC Bricks excel due to their superior wear resistance and chemical stability. They withstand the abrasive action of raw materials and corrosive gases, ensuring longer furnace life and consistent product quality. Whether firing pottery or melting glass, these bricks maintain structural integrity at extreme temperatures.

3. Chemical Processing

Chemical reactors and incinerators often handle aggressive substances and high heat. Silicon Carbide Bricks resist corrosion from acids, alkalis, and molten salts, making them indispensable for processes like sulfuric acid production and waste incineration. Their low porosity prevents chemical penetration, ensuring safety and durability.

4. Energy Sector

Power plants, especially those using coal or biomass, rely on SiC Bricks for boiler linings and heat exchangers. Their ability to withstand high pressures and thermal cycling ensures reliable operation, reducing downtime and maintenance needs. Additionally, they are used in nuclear reactors for their radiation resistance.

5. Aerospace and Defense

In aerospace applications, such as rocket nozzles and jet engine components, Silicon Carbide Bricks provide exceptional heat resistance and structural strength. They are also used in defense for armor plating and high-temperature weapon systems, thanks to their hardness and impact resistance.

Why Choose Silicon Carbide Bricks?

Thermal Shock Resistance: Withstands rapid temperature changes without cracking.

High Strength: Maintains structural integrity at extreme temperatures.

Wear Resistance: Resists abrasion from raw materials and mechanical stress.

Chemical Stability: Unaffected by corrosive substances and gases.

Energy Efficiency: Reduces heat loss, lowering fuel consumption.

Conclusion

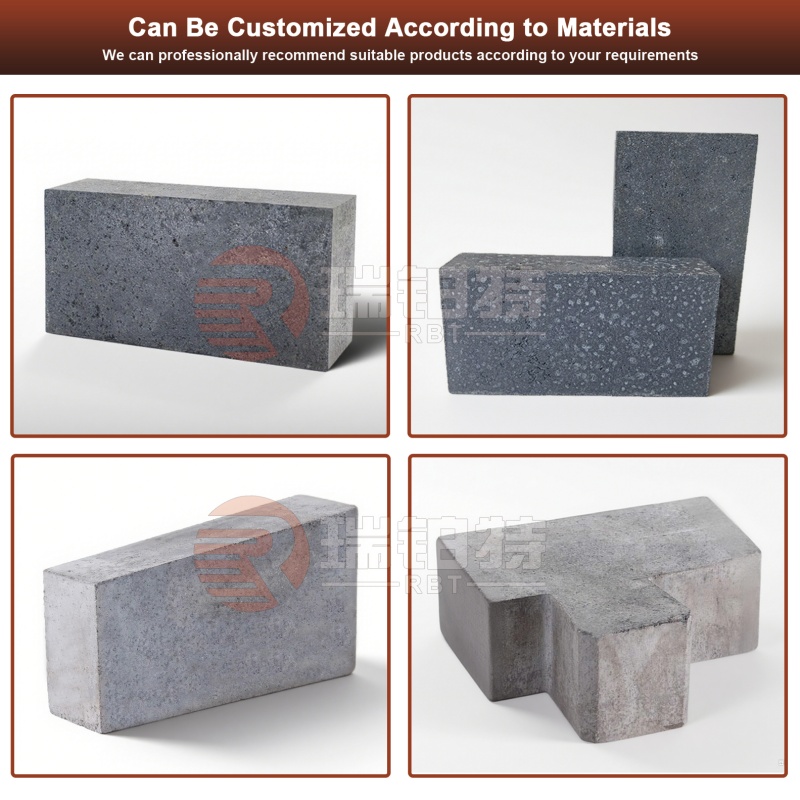

Silicon Carbide Bricks are a versatile and reliable material, driving innovation across industries. From metallurgy to aerospace, their unique properties ensure optimal performance in the most demanding environments. If you’re looking to enhance furnace efficiency, reduce maintenance costs, and improve product quality, Silicon Carbide Bricks are the solution. Contact us today to learn more about our custom SiC Brick solutions tailored to your industry needs.

Post time: Sep-09-2025