In the world of high - temperature industrial applications, SK32 and SK34 bricks stand out as reliable and high - performance refractory solutions. These bricks are part of the SK series of fireclay bricks, renowned for their exceptional heat resistance and durability.

1. Composition and Manufacturing

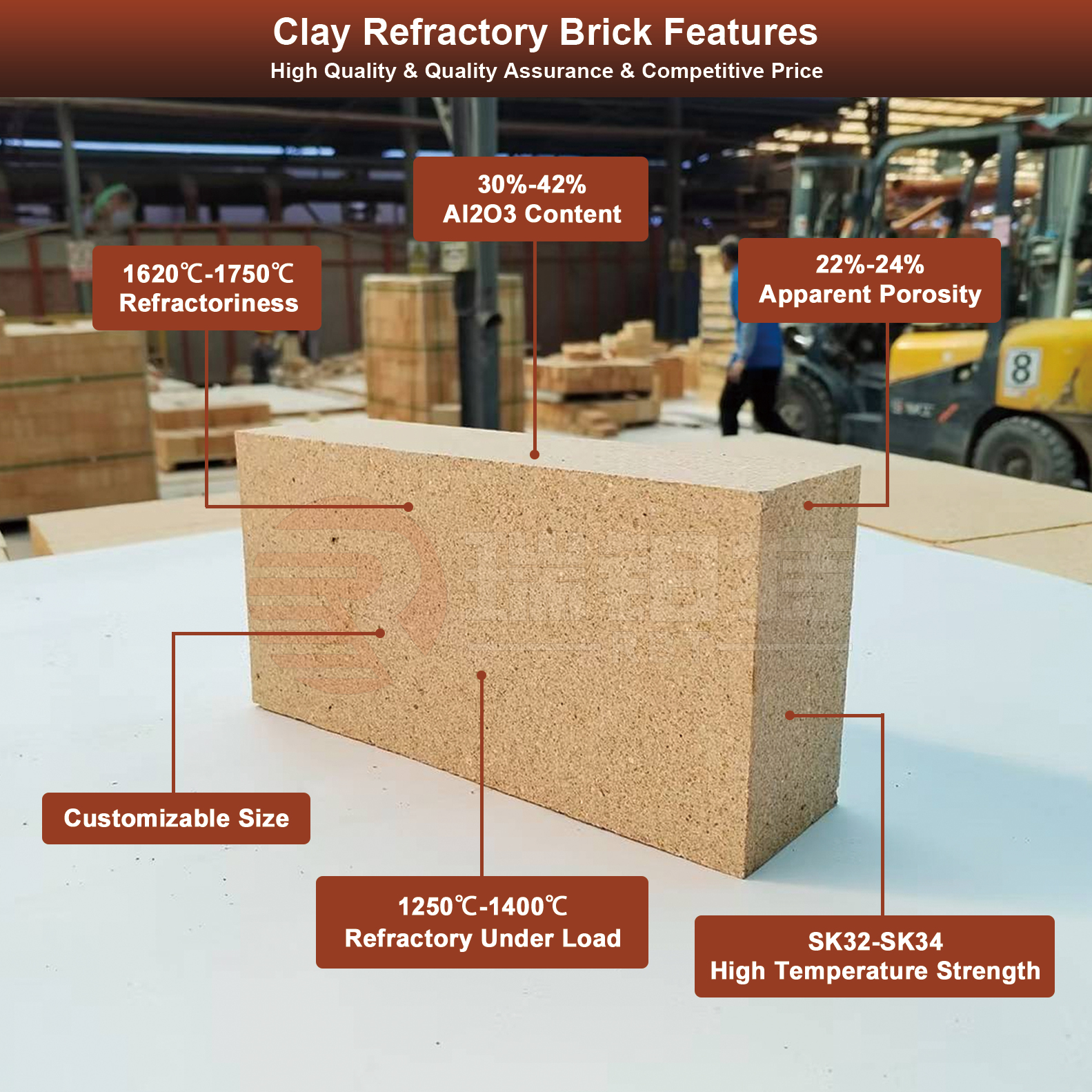

SK32 and SK34 fireclay bricks are crafted from the finest raw materials, including refractory clay, calcined chamotte, and mullite. The manufacturing process involves advanced techniques that ensure the bricks have a low porosity, high strength, and excellent resistance to thermal spalling, abrasion, and corrosion.

SK32 Brick

SK32 bricks typically contain 35 - 38% alumina. This composition gives them a refractoriness of ≥1690 °C and a refractoriness under load (0.2 MPa) of ≥1320 °C. They have an apparent porosity of 20 - 24% and a bulk density of 2.05 - 2.1 g/cm³.

SK34 Brick

SK34 bricks, on the other hand, have a higher alumina content, ranging from 38 - 42%. This results in a higher refractoriness of ≥1710 °C and a refractoriness under load (0.2 MPa) of ≥1340 °C. Their apparent porosity is 19 - 23%, and the bulk density is 2.1 - 2.15 g/cm³.

2. Applications

Due to their outstanding properties, SK32 and SK34 bricks find extensive use in a variety of high - temperature industries.

Steel Plants

In steel manufacturing, SK34 bricks are the go - to choice for furnace linings, ladles, and other high - temperature equipment. The extreme heat conditions in steel plants demand materials with maximum heat resistance, and SK34 bricks fit the bill perfectly. They can withstand the intense heat and protect the underlying structures from damage.

SK32 bricks, with their slightly lower heat resistance but still impressive performance, are often used in areas of the steel plant that are exposed to moderate heat, such as certain furnace linings where the temperature requirements are not as extreme.

Ceramics Industry

Both SK32 and SK34 bricks are commonly used in ceramic kilns. SK32 bricks are suitable for kilns that operate at moderately high temperatures, providing reliable insulation and heat resistance. SK34 bricks, with their higher heat - resistant capabilities, are used in kilns where even more extreme temperatures are involved, ensuring the quality of the ceramic products during firing.

Cement Plants

In cement rotary kilns, SK32 and SK34 bricks play a crucial role. The long - term exposure to high temperatures and abrasive materials in cement plants requires refractory bricks with excellent mechanical strength and wear resistance. SK32 bricks are used in sections of the kiln where the heat is not at the highest levels, while SK34 bricks are installed in the areas subjected to the most severe heat, such as the burning zone of the kiln.

Petrochemical and Chemical Plants

SK34 bricks are widely used in reactors and thermal equipment in petrochemical and chemical plants. These plants often deal with high - temperature chemical reactions, and SK34 bricks' ability to resist heat and chemical corrosion makes them an ideal choice. SK32 bricks may also be used in some applications within these plants where the temperature conditions are more moderate.

3. Advantages

SK32 and SK34 bricks offer several advantages that make them highly desirable in high - temperature applications.

Excellent Heat Resistance

As mentioned earlier, both types of bricks can withstand high temperatures. The high refractoriness and good performance under load ensure that they can maintain their structural integrity even in the most demanding heat - intensive environments.

Low Thermal Conductivity

They have low thermal conductivity, which means they minimize heat loss. This property is not only beneficial for maintaining the desired temperature within the industrial equipment but also helps in reducing energy consumption. By preventing heat from escaping, the plants can operate more efficiently and cost - effectively.

High Mechanical Strength

SK32 and SK34 bricks possess high mechanical strength. This allows them to endure the mechanical stress, abrasion, and impact that occur in industrial settings. Their structural integrity ensures a long service life, reducing the need for frequent replacements and thus saving on maintenance costs.

Good Resistance to Thermal Spalling and Corrosion

The bricks are highly resistant to thermal spalling, which is the cracking or peeling of the material due to rapid temperature changes. They also offer excellent resistance to corrosion, especially in chemical - rich environments. This makes them suitable for use in a wide range of industries where such challenges are common.

4. Choosing the Right Brick

When deciding between SK32 and SK34 bricks for a particular application, several factors need to be considered.

Temperature Requirements

The most crucial factor is the temperature that the brick will be exposed to. If the application involves extremely high temperatures, such as in steel - making furnaces or certain high - temperature kilns, SK34 bricks are the obvious choice. However, for applications with moderately high temperatures, SK32 bricks can provide a more cost - effective solution without sacrificing too much on performance.

Chemical Environment

The chemical composition of the environment where the brick will be used is also important. In environments with high levels of corrosive chemicals, SK34 bricks' better corrosion resistance may be necessary. But if the chemical exposure is minimal, SK32 bricks may be sufficient.

Cost Considerations

SK32 bricks are generally more cost - effective than SK34 bricks. If the temperature and chemical requirements of the application allow, using SK32 bricks can help in reducing the overall project costs. However, it is essential not to compromise on performance for the sake of cost savings.

In conclusion, SK32 and SK34 bricks are two of the most reliable refractory materials available for high - temperature industrial applications. Their unique properties, wide range of applications, and cost - effectiveness make them an ideal choice for various industries. Whether it's a steel plant, a ceramics factory, a cement plant, or a petrochemical facility, these bricks can provide the necessary heat resistance and durability to ensure smooth and efficient operations.

Post time: Aug-04-2025