In various links of industrial production, casting steel bricks, as a key material with special properties, play an irreplaceable role. With their excellent high-temperature resistance, corrosion resistance and other characteristics, they have been widely used in multiple fields, providing an important guarantee for the smooth progress of industrial production.

A Key Role in Metallurgical Casting

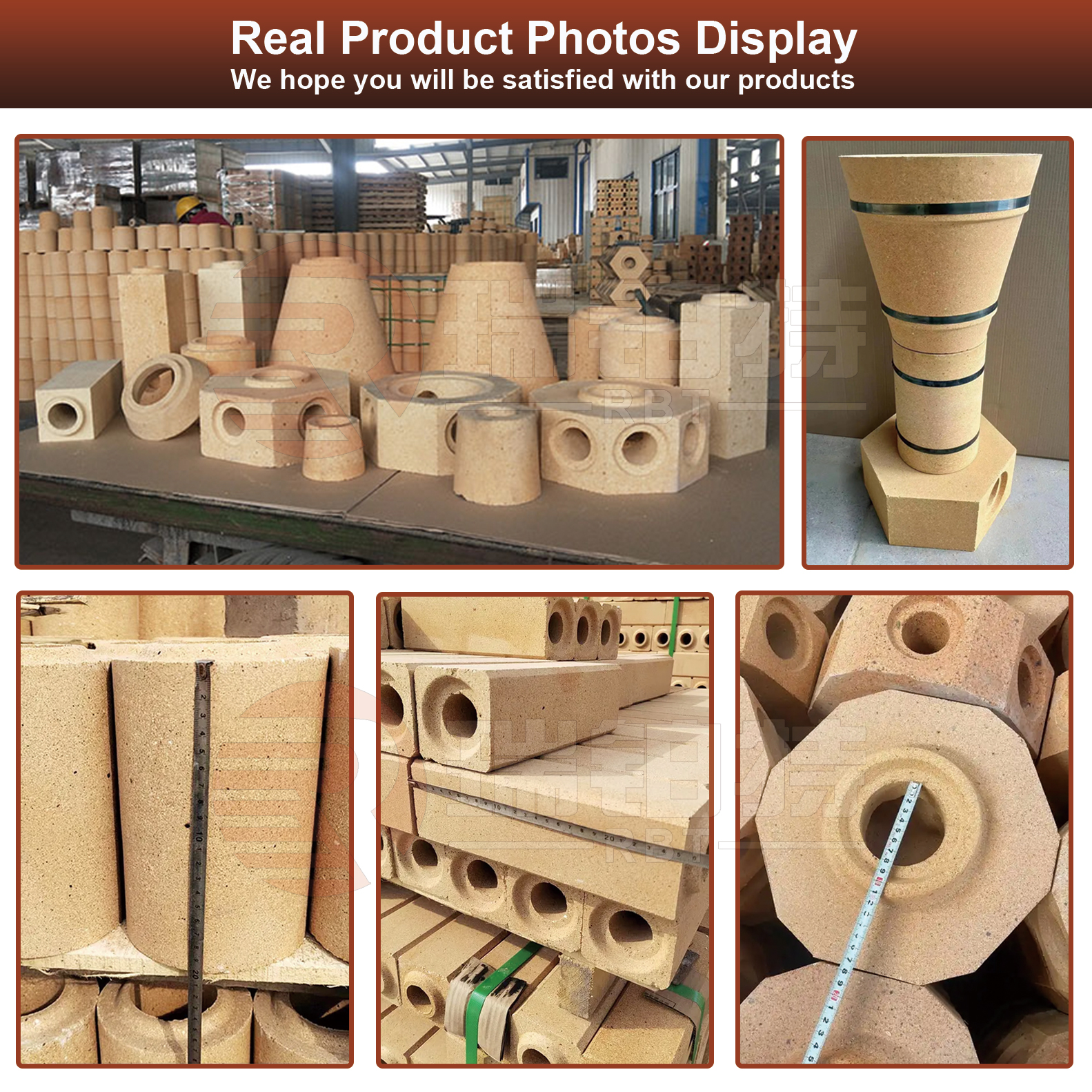

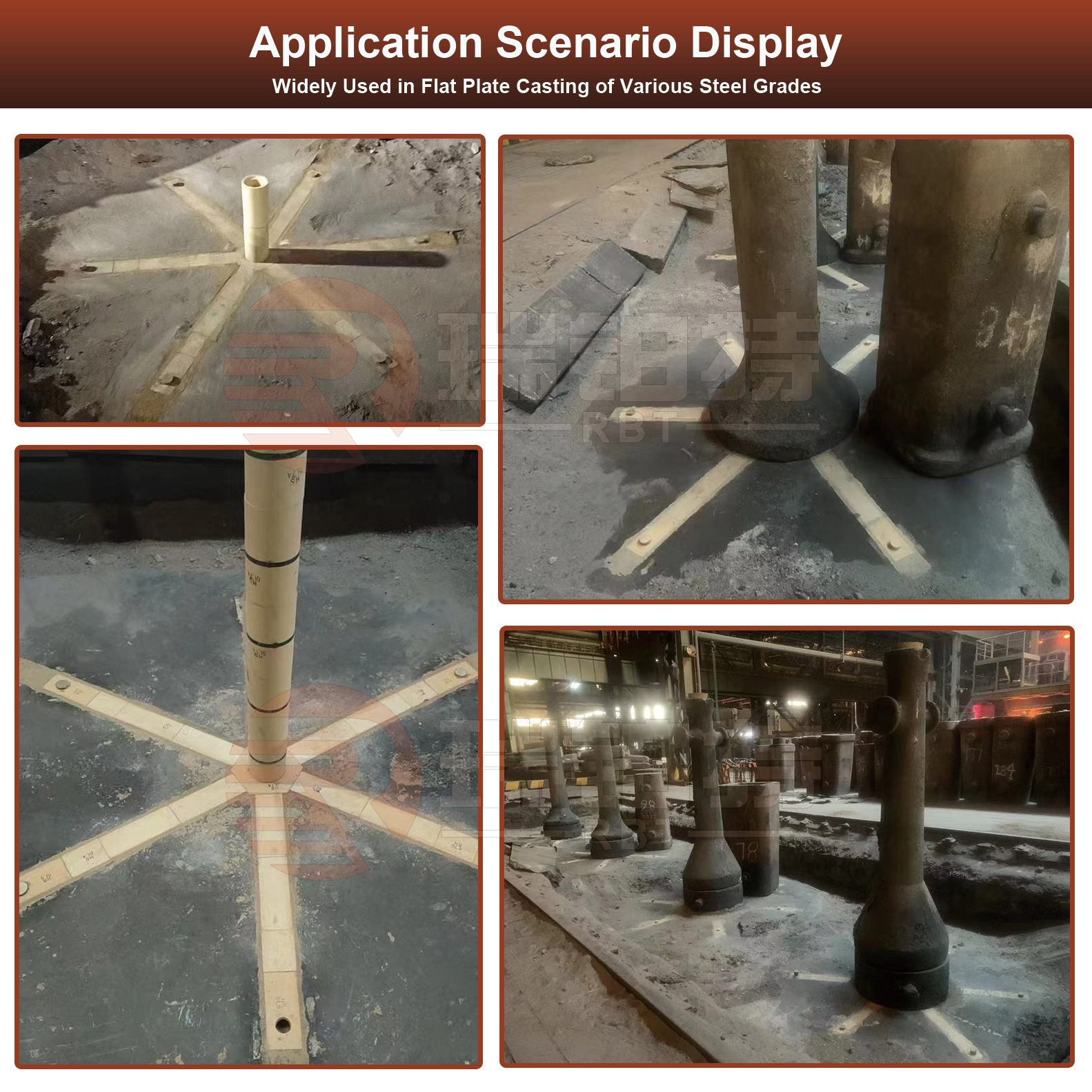

In the metallurgical casting industry, casting steel bricks are indispensable core materials. Their main purpose is to serve as a channel for molten steel to flow from the ladle to the ingot mold in the bottom casting process. Specifically, casting steel bricks are built into the grooves of the ingot casting base plate, with one end connected to the steel distribution brick and the other end connected to the ingot mold, forming a key path for the flow of molten steel. Therefore, they are often called "tundish bricks" by insiders.

During the molten steel pouring process, the temperature of high-temperature molten steel is extremely high, often reaching thousands of degrees Celsius, which puts extremely high requirements on the high-temperature resistance of casting steel bricks. At the same time, the molten steel will have a strong impact and scouring on the brick body during the flow process, and the molten steel itself will also have certain chemical reactions with the brick body. High-quality casting steel bricks can withstand these tests and ensure the smooth flow of molten steel. Its inner hole is smooth, which can effectively reduce the resistance when the molten steel flows, avoid turbulent flow during the flow of molten steel, thereby reducing the generation of defects such as bubbles and inclusions in the ingot, and improving the quality of the ingot. Whether it is the flat casting of stainless steel, alloy steel or ordinary carbon steel, casting steel bricks can be well adapted to provide stable support for the casting of different steel types.

An Important Lining Material for Industrial Furnaces

Industrial furnaces are core equipment in many industrial production processes, such as blast furnaces and hot blast stoves in the iron and steel industry, and reaction furnaces in the chemical industry. These furnaces usually need to operate in high-temperature environments, and the internal environment is extremely harsh. Casting steel bricks, with their excellent high-temperature resistance and corrosion resistance, have become an ideal choice for the lining of industrial furnaces.

Using casting steel bricks as the lining of industrial furnaces can effectively resist the high-temperature baking in the furnace and the erosion of various corrosive gases and liquids. It can protect the shell structure of the furnace, avoid deformation and damage of the furnace body due to high temperature, and prolong the service life of the furnace. At the same time, casting steel bricks have good thermal insulation performance, which can reduce the loss of heat in the furnace, improve energy utilization efficiency, and reduce production energy consumption. In some furnaces that need precise temperature control, the stable performance of casting steel bricks can also help maintain the uniformity of the temperature in the furnace, ensure the stability of the production process, and thus improve product quality.

Protective Application in Special Pipeline Systems

In some industrial productions, there are special pipeline systems for transporting high-temperature and high-pressure media (such as high-temperature steam, molten metal, etc.). These pipelines are in harsh working conditions for a long time and are prone to scouring, corrosion and high-temperature damage by the media, which affects the safety and service life of the pipelines.

Casting steel bricks can be used for the protection of key parts of these special pipeline systems. By building casting steel bricks in specific positions inside or outside the pipeline, a solid protective barrier can be formed to resist the direct impact and erosion of the medium on the pipeline. Especially at the turning points and interfaces of the pipeline, which are prone to wear and corrosion, the protective effect of casting steel bricks is more obvious. It can effectively reduce the wear rate of the pipeline, reduce the risk of pipeline leakage, ensure the safe and stable operation of the pipeline system, reduce production interruptions caused by pipeline maintenance, and improve production efficiency.

Casting steel bricks, with their unique properties, have important applications in metallurgical casting, industrial furnaces, special pipeline systems and other fields. With the continuous development of industrial production technology, the requirements for the performance of casting steel bricks are constantly increasing. In the future, their application range is expected to further expand, providing reliable material support for more industrial fields. If you are looking for suitable high-temperature resistant and corrosion-resistant materials for related industrial projects, casting steel bricks are undoubtedly a high-quality choice worth considering.

Post time: Aug-01-2025