In the ever-evolving realm of industrial heating solutions, our silicon carbide (SiC) heating elements shine as a benchmark of innovation, reliability, and high performance. Crafted with cutting-edge technology and premium materials, they are redefining heating processes across diverse industries.

Exceptional High-Temperature Performance

Engineered to excel in the most extreme high-temperature settings, our silicon carbide heating elements operate seamlessly at temperatures up to 1625°C (2957°F). They maintain structural stability and heating efficiency even under such intense conditions, outperforming traditional heating elements by a significant margin. This remarkable heat resistance makes them the top choice for applications like high-temperature furnaces, where precise and stable heating is non-negotiable.

Unmatched Durability and Longevity

Built for endurance, our silicon carbide heating elements boast superior resistance to oxidation, corrosion, and thermal stress. The inherent properties of silicon carbide allow them to withstand continuous use in harsh industrial environments, greatly extending their service life. This durability reduces the need for frequent replacements, minimizes downtime, and ultimately boosts productivity while cutting operational costs.

Superior Energy Efficiency

In an age of growing environmental awareness and emphasis on energy conservation, our silicon carbide heating elements offer a sustainable heating solution. They convert electrical energy to heat with minimal loss, achieving high energy utilization rates. This not only lowers your energy consumption and operating expenses but also contributes to a greener, more sustainable future.

Precise and Uniform Heating

Precise, uniform temperature distribution is critical in many industrial processes. Our silicon carbide heating elements are designed to deliver stable, consistent heat output, eliminating hot spots and temperature fluctuations. This precision ensures your products are processed under optimal conditions, enhancing quality and reducing variability.

Wide-Ranging Industrial Applications

Our silicon carbide heating elements are widely used across various industries:

Steel Industry: In steel production, especially for billet heating and special steel heat treatment, our AS elements provide the required high thermal load while maintaining uniform temperatures. This improves rolled steel quality and reduces energy use and downtime.

Glass Industry: For glass manufacturing, our SG elements precisely control temperatures in glass feeders and melting stages. They resist corrosion from molten glass, ensuring stable, high-quality production.

Lithium-Ion Battery Industry: Precise temperature control is vital for cathode calcination and anode heat treatment in battery production. Our SD and AS elements provide the uniform high-temperature environment needed to optimize material consistency and energy density.

Ceramics and Semiconductor Industries: Whether for ceramic sintering or semiconductor manufacturing, our silicon carbide heating elements can be customized to meet specific industry needs, delivering the high-temperature stability and precision required for high-quality production.

Customized Solutions for Your Needs

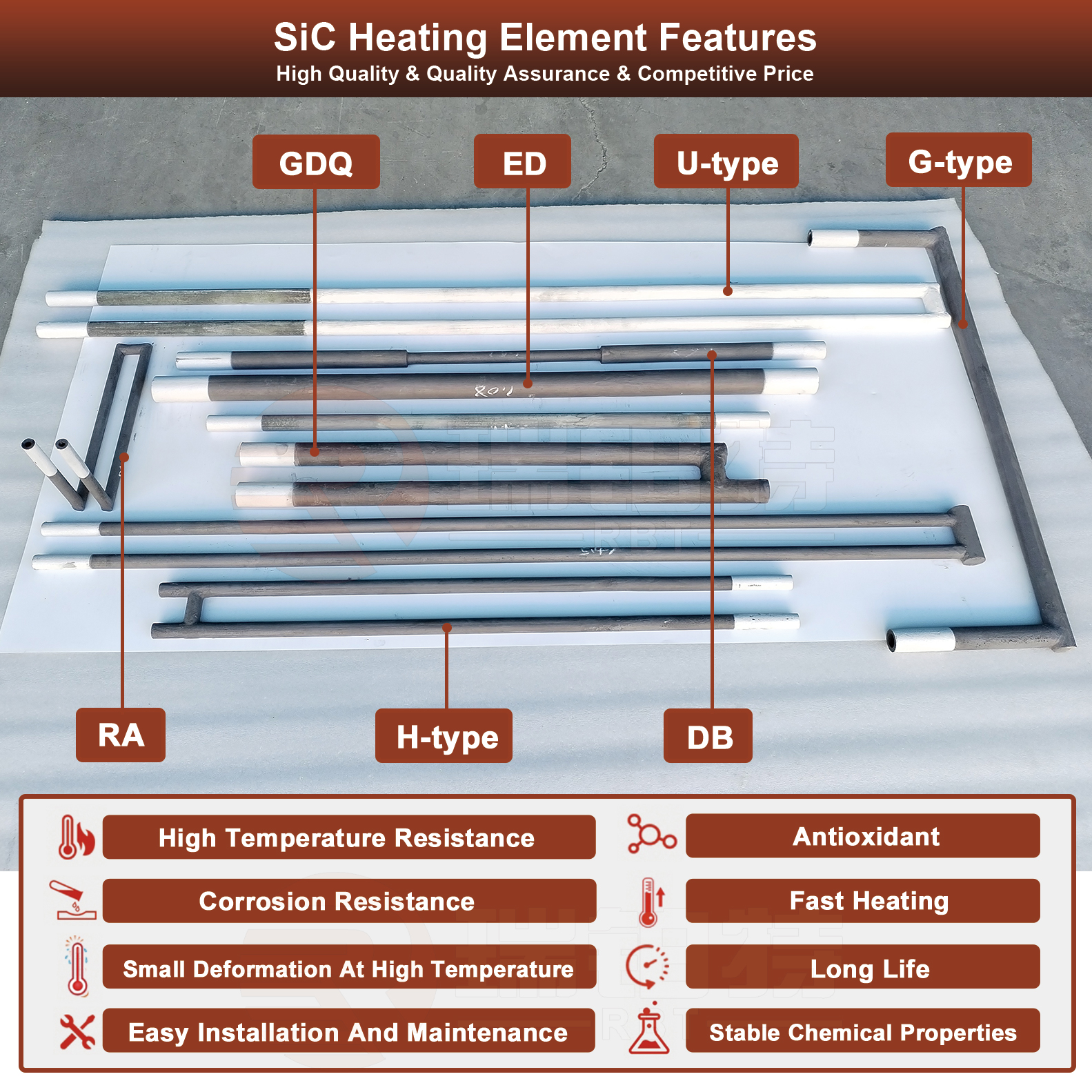

We recognize that every industrial process is unique. That’s why we offer a comprehensive range of heating elements, customizable to your specific application requirements. Our expert team will collaborate closely with you to understand your needs and develop tailored solutions that deliver optimal performance and efficiency.

Choosing our silicon carbide heating elements means more than investing in a heating solution—it means partnering with a team dedicated to helping you achieve production goals, enhance product quality, and increase profitability. Contact us today to discover how our silicon carbide heating elements can transform your industrial heating processes.

Post time: Jul-28-2025