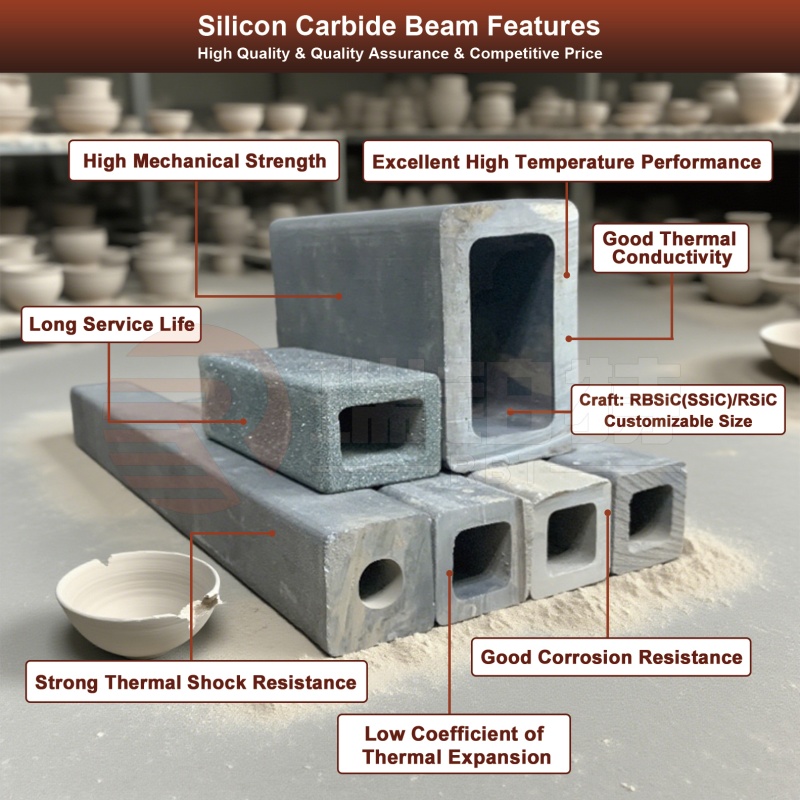

In the field of high-temperature industrial applications, Silicon Carbide (SiC) beams have emerged as a groundbreaking solution. Professionally engineered, these beams boast unique comprehensive properties, offering significant advantages over traditional materials.

Exceptional High-Temperature Resistance

Silicon Carbide beams are renowned for their outstanding high-temperature tolerance. In certain scenarios, they can operate at temperatures up to 1380°C or even higher while maintaining stable technical parameters. This high-temperature stability ensures that the beams do not bend or deform during long-term use, providing a reliable and durable solution for industrial kilns. Whether it is a tunnel kiln, shuttle kiln, or roller kiln, Silicon Carbide beams are the ideal choice for load-bearing structural systems.

Superior Strength and Hardness

With high strength and hardness, Silicon Carbide beams can withstand heavy loads. Their load-bearing capacity at high temperatures is particularly prominent, which is crucial for application scenarios that require supporting large quantities of materials during the firing process. Additionally, the high hardness endows the beams with excellent wear resistance, making them suitable for environments where abrasion is a concern. This durability ensures a long service life for the beams, reducing the need for frequent replacements and thereby lowering maintenance costs.

Comprehensive Corrosion Resistance, Oxidation Resistance, and More

Silicon Carbide beams exhibit excellent resistance to various external factors. They possess strong corrosion resistance, making them highly suitable for industrial scenarios involving frequent contact with corrosive substances. Oxidation resistance is another key advantage, effectively preventing the beams from aging and damage due to oxygen exposure in high-temperature environments. Furthermore, Silicon Carbide beams also have good heat resistance and thermal shock resistance. They can quickly adapt to sudden temperature changes without cracking or breaking, ensuring stable operation in kilns with frequent temperature fluctuations.

Significant Energy-Saving Advantages

Leveraging their excellent thermal conductivity, Silicon Carbide beams enable efficient heat transfer. This feature not only helps improve the uniformity of heat distribution inside the kiln but also achieves energy-saving effects. By enhancing the thermal efficiency of the kiln, enterprises can reduce energy consumption without increasing the weight of kiln cars, resulting in substantial cost savings in the long run.

Wide Range of Applications

The versatility of Silicon Carbide beams allows them to be widely used across multiple industries. In the ceramic industry, they are the preferred material for firing electrical porcelain, tableware, and sanitary ware. In the building materials industry, they can be used for producing high-quality refractory materials. In the magnetic materials industry, they are also applied in high-temperature firing processes. In fact, any industry that requires reliable, high-performance load-bearing structures in high-temperature environments can benefit from the application of Silicon Carbide beams.

Customizable to Your Requirements

We fully understand that different industrial application scenarios have unique needs. Therefore, we offer customized production services, manufacturing Silicon Carbide beams according to your specific requirements. Whether it comes to size, shape, or other technical parameters, we can create beam products that fully meet your needs by leveraging advanced production processes such as slip casting and extrusion molding.

Choose Silicon Carbide beams for your next high-temperature project and experience their outstanding performance in terms of functionality, durability, and energy efficiency. Contact us now to gain a deeper understanding of how Silicon Carbide beams can transform your industrial production.

Post time: Aug-25-2025