In the world of high - temperature industrial processes, the choice of kiln components can make or break the efficiency, quality, and longevity of your operations. Among these critical components, silicon carbide kiln plates stand out as a game - changing solution, offering a plethora of benefits that can revolutionize your kiln performance.

Exceptional Heat Resistance

Silicon carbide (SiC) is renowned for its remarkable heat - resistant properties. Kiln plates made from this advanced material can withstand extreme temperatures, often reaching up to 1600°C or even higher in some specialized applications. This high - temperature tolerance ensures that the plates maintain their structural integrity, even in the most demanding kiln environments. Whether you're firing ceramics, melting metals, or conducting other high - temperature processes, silicon carbide kiln plates provide a reliable and stable platform that won't warp, crack, or degrade under intense heat.

Superior Thermal Conductivity

One of the key advantages of silicon carbide kiln plates is their exceptional thermal conductivity. SiC has a much higher thermal conductivity compared to traditional kiln plate materials such as refractory clay or alumina. This means that heat is rapidly and evenly distributed across the plate surface, minimizing temperature gradients within the kiln. As a result, your products are subjected to a more uniform heat treatment, leading to improved quality, reduced firing times, and enhanced energy efficiency. With silicon carbide kiln plates, you can achieve more consistent results in your kiln operations, while also saving on energy costs in the long run.

Outstanding Mechanical Strength

In addition to their heat - resistant and thermal - conductive properties, silicon carbide kiln plates boast impressive mechanical strength. They are highly resistant to mechanical stress, including the weight of heavy loads and the impact of materials being placed or removed from the kiln. This strength ensures that the plates have a long service life, even in industrial settings where they may be subjected to frequent use and handling. The high mechanical strength of silicon carbide also makes it possible to design thinner and lighter kiln plates without sacrificing performance, which can be beneficial for optimizing kiln space and reducing overall equipment weight.

Excellent Chemical Resistance

Industrial kiln processes often involve exposure to various chemicals, gases, and corrosive substances. Silicon carbide kiln plates offer excellent chemical resistance, making them suitable for use in environments where traditional materials may corrode or degrade over time. Whether it's the acidic or alkaline atmospheres commonly found in certain firing processes or the presence of reactive gases in metal - melting applications, silicon carbide plates can withstand these chemical challenges without losing their integrity. This chemical resistance not only extends the lifespan of the kiln plates but also helps to maintain a clean and contaminant - free kiln environment, which is crucial for producing high - quality products.

Versatile Applications

The unique properties of silicon carbide kiln plates make them suitable for a wide range of applications across multiple industries. In the ceramics industry, they are widely used as support plates for firing delicate porcelain, pottery, and ceramic tiles. The high - temperature stability and uniform heat distribution provided by silicon carbide plates ensure that ceramic products are fired evenly, resulting in consistent colors, textures, and glaze finishes.

In the metallurgical industry, silicon carbide kiln plates play a vital role in processes such as metal melting, casting, and heat treatment. They can withstand the intense heat and corrosive nature of molten metals, providing a reliable surface for holding and processing metal materials. Additionally, in the electronics industry, silicon carbide kiln plates are used in the production of semiconductors and other electronic components, where precise temperature control and a clean firing environment are essential.

Choosing the Right Silicon Carbide Kiln Plates

When selecting silicon carbide kiln plates for your specific application, it's important to consider several factors. First, you need to determine the maximum temperature requirements of your kiln process. Different grades of silicon carbide are available, each with its own temperature tolerance range, so choosing the right grade is crucial for ensuring optimal performance.

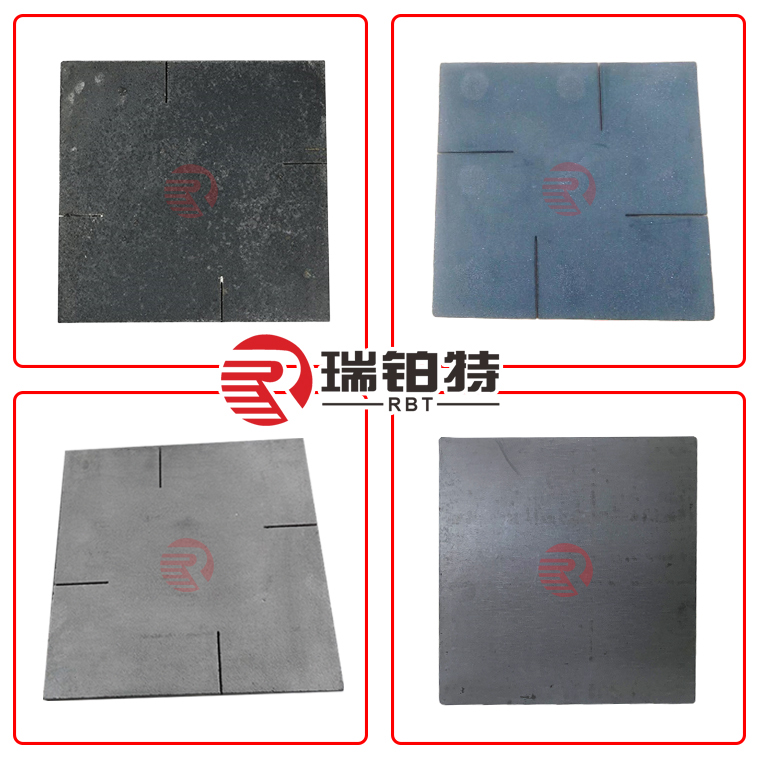

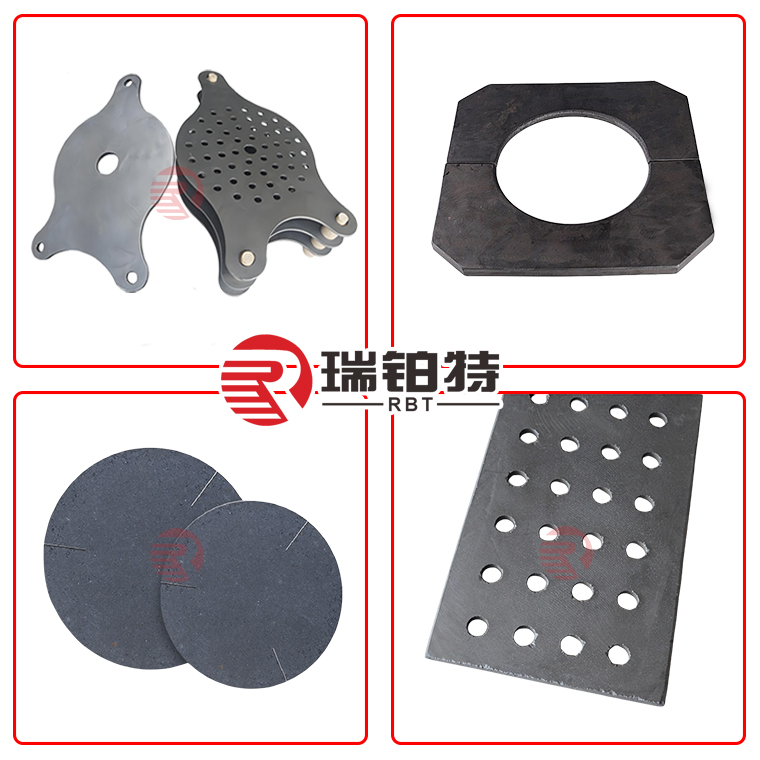

You should also consider the size and shape of the kiln plates. They need to fit your kiln dimensions precisely to ensure proper heat distribution and efficient operation. Additionally, factors such as the surface finish of the plates, their porosity, and their compatibility with the materials being processed in the kiln should be taken into account.

In conclusion, silicon carbide kiln plates offer a host of advantages that can significantly enhance the performance and productivity of your kiln operations. With their exceptional heat resistance, superior thermal conductivity, outstanding mechanical strength, and excellent chemical resistance, these plates are a reliable and versatile solution for a wide range of high - temperature industrial applications. By choosing the right silicon carbide kiln plates for your needs and working with a trusted supplier, you can unlock the full potential of your kiln and take your industrial processes to the next level.

Post time: Jul-07-2025