RBSiC Protection Tube

Product Information

Silicon carbide Protection tubes are special tubular components made of silicon carbide (SiC) ceramic material, primarily used to protect sensitive elements (such as thermocouples) or as core components in high-temperature fluid transport and heat exchange equipment.

Our products are mainly manufactured using three processes: Reaction sintering (RBSiC), Recrystallization (RSiC), Silicon nitride bonded silicon carbide (NSiC)

1. RBSiC protection tubes

Using SiC particles and graphite as raw materials, the material undergoes a silicon infiltration process. Liquid silicon permeates and fills the pores, reacting with the graphite to form a new SiC phase, ultimately creating a composite structure of "SiC framework + free silicon".

Key Characteristics:

High density and low porosity: Free silicon fills the pores, reducing porosity to below 1%, resulting in excellent airtightness and high-pressure resistance, suitable for high-pressure and high-temperature

sealing conditions (such as pressure sintering furnaces).

Good mechanical properties: Room temperature flexural strength 250–400MPa, high fracture toughness, and impact resistance superior to recrystallized silicon carbide.

Moderate high-temperature resistance: Long-term operating temperature is 1200℃. Above 1350℃, free silicon softens, leading to a decrease in strength and limiting high-temperature performance.

Good processability: The presence of free silicon reduces material brittleness, making it easy to machine into complex shapes, resulting in relatively low production costs.

Limitations:

High-temperature performance is limited by free silicon, making it unsuitable for long-term operation above 1350℃; free silicon readily reacts with strong alkalis, molten aluminum, etc., resulting in a narrow corrosion resistance range.

2. RSiC protection tubes

Using high-purity SiC micro powder as raw material, it is sintered at high temperatures (2000–2200℃). A dense structure is formed through the recrystallization and grain boundary fusion of the SiC particles themselves, with no additional bonding phase.

Core Characteristics:

Exceptional High-Temperature Resistance: Long-term operating temperature up to 1600℃, short-term resistance to 1800℃, making it the best in terms of high-temperature resistance among the three types, suitable for ultra-high-temperature kilns (such as ceramic sintering kilns and metallurgical blast furnaces).

Excellent Oxidation Resistance: At high temperatures, a dense SiO₂ protective film forms on the surface, preventing further oxidation of the internal SiC, exhibiting extremely high stability in oxidizing atmospheres.

Extremely Low Coefficient of Thermal Expansion: The coefficient of thermal expansion is only 4.5 × 10⁻⁶ /℃, providing good thermal shock resistance, although slightly lower than that of silicon nitride-bonded silicon carbide.

High hardness and high wear resistance: With a Mohs hardness close to 9, it exhibits outstanding resistance to material erosion and abrasion, making it suitable for high-temperature airflow and liquid flow conditions containing solid particles.

Strong chemical stability: Resistant to strong acids and alkalis, and does not react with most molten metals.

Limitations:

Extremely high sintering temperature, resulting in slightly higher porosity (approximately 5%–8%) and slightly weaker high-pressure resistance; relatively high room-temperature brittleness, and impact resistance is not as good as silicon nitride-bonded silicon carbide.

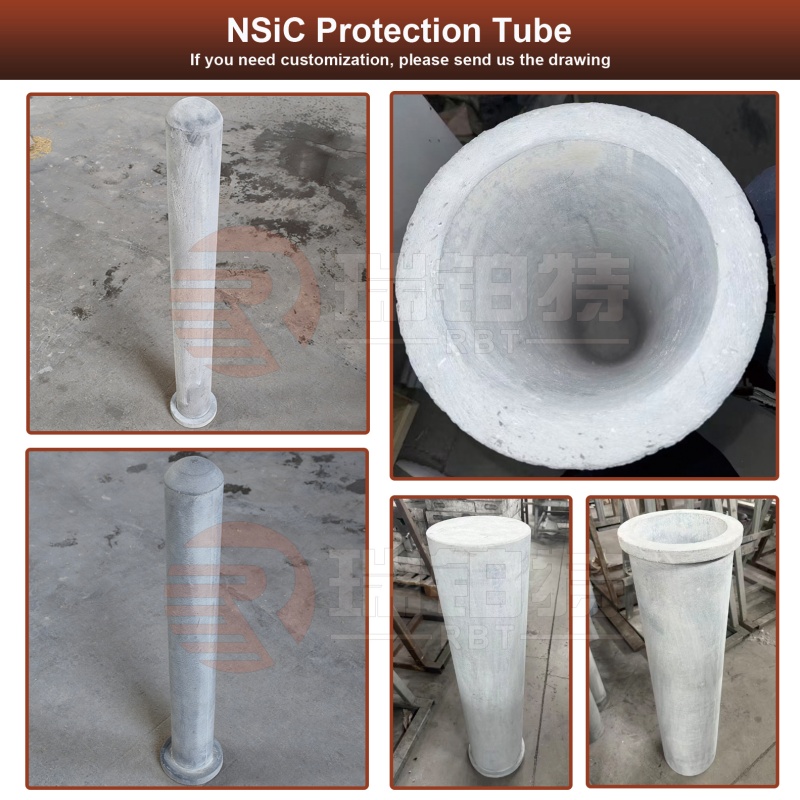

3. NSiC protection tube

It is a composite material formed by tightly connecting SiC particles in a silicon carbide matrix by generating Si₃N₄ as a binding phase through a nitriding reaction.

Key Features:

1. Ultra-high Thermal Shock Resistance: The low coefficient of thermal expansion and high toughness of the Si₃N₄ bonded phase allow the protective tube to withstand rapid heating and cooling above 1000℃ without cracking due to sudden temperature changes, making it suitable for operating conditions with frequent temperature fluctuations.

2. Excellent Corrosion Resistance: Extremely stable against strong acids, strong alkalis, molten metals (such as aluminum and copper), and molten salts, making it particularly suitable for corrosive environments in the chemical and metallurgical industries.

3. High Mechanical Strength: Room temperature flexural strength reaches 300–500 MPa, with better strength retention at high temperatures than pure SiC products, and strong impact resistance.

4. Operating Temperature: Long-term operating temperature 1350℃, short-term withstand capability up to 1500℃.

5. Good Insulation: Maintains good electrical insulation even at high temperatures, preventing thermocouple signal interference.

Limitations:

Oxidation resistance is slightly inferior to recrystallized silicon carbide; long-term use in strong oxidizing atmospheres may lead to surface oxide layer peeling.

Core Features Comparison Table

|

Characteristic

|

Si₃N₄-SiC

|

R-SiC

|

RB-SiC

|

|

Long-term Operating Temperature

|

1350℃

|

1600℃

|

1200℃

|

|

Thermal Shock Resistance

|

Optimal

|

Good

|

Medium

|

|

Antioxidant Properties

|

Good

|

Optimal

|

Medium

|

|

Corrosion Resistance

|

Strong (resistant to acids and alkalis /molten metal)

|

Strong (resistant to oxidation and corrosion)

|

Medium (Avoid strong alkalis/molten aluminum)

|

|

Porosity

|

3%–5%

|

5%–8%

|

<1%

|

|

Impact Resistance

|

Powerful

|

Weak

|

Medium

|

Typical Industries and Scenarios

1. NSiC thermocouple protection tube

Chemical Industry: Temperature measurement in acid-base reaction vessels, molten salt electrolytic cells, and corrosive medium storage tanks; withstands long-term corrosion from strong acids, alkalis, and molten salts; suitable for intermittent reaction conditions with frequent temperature fluctuations.

Metallurgical Industry: Temperature measurement of molten metal in aluminum die-casting molds, copper smelting furnaces, and non-ferrous metal smelting furnaces; resistant to molten metal erosion, and its high-temperature insulation avoids thermocouple signal interference.

Building Materials Industry: Temperature measurement in intermittent lime kilns and gypsum calcining furnaces; able to cope with rapid heating and cooling caused by kiln start-up and shutdown; resistant to corrosion from alkaline flue gas inside the kiln.

2. RSiC Thermocouple Protection Tubes

Building Materials Industry: Temperature measurement in cement rotary kiln firing zones, ceramic roller kilns, and refractory material tunnel kilns; withstands ultra-high temperatures of 1600℃ and strong erosion from high-temperature powders, suitable for continuous high-temperature production conditions.

Metallurgical Industry: Temperature measurement in blast furnace hot blast pipes, molten steel ladles, and molten iron pretreatment devices; can be used long-term in strong oxidizing atmospheres, resisting corrosion from high-temperature flue gas and iron slag.

Glass Industry: Temperature measurement in glass melting furnace regenerators and glass forming molds; withstands high-temperature corrosion and erosion from molten glass, meeting the continuous high-temperature requirements of glass production.

3. RBSiC Thermocouple Protection Tubes

Machinery Manufacturing Industry: Temperature measurement in heat treatment furnaces, gas-fired quenching furnaces, and carburizing furnaces; suitable for stable medium and low temperature conditions, and can withstand mild in-furnace particle erosion.

Power Industry: Temperature measurement for atmospheric pressure boilers, hot blast stoves, and waste heat recovery devices; suitable for neutral or weakly oxidizing atmospheres, meeting the sealed temperature measurement requirements from low to medium-high pressure.

Experimental Equipment: Temperature measurement for small high-pressure sintering furnaces and laboratory tubular furnaces; its low porosity and airtightness make it suitable for small-space, high-pressure sealed experimental environments.

Metallurgical

Chemical

Power

Aerospace

Electronic

Roller Kilns

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

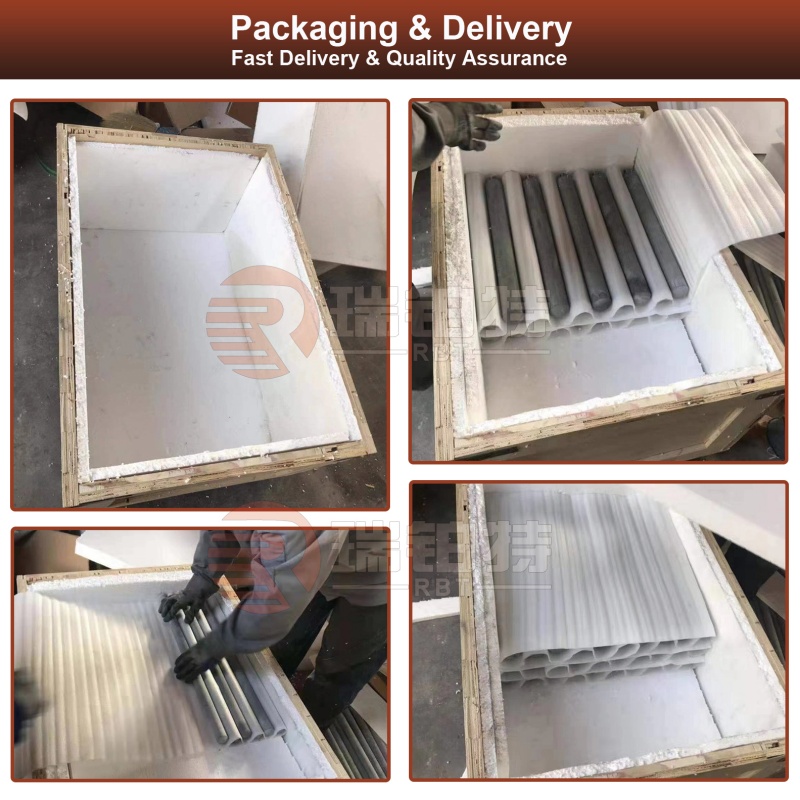

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.