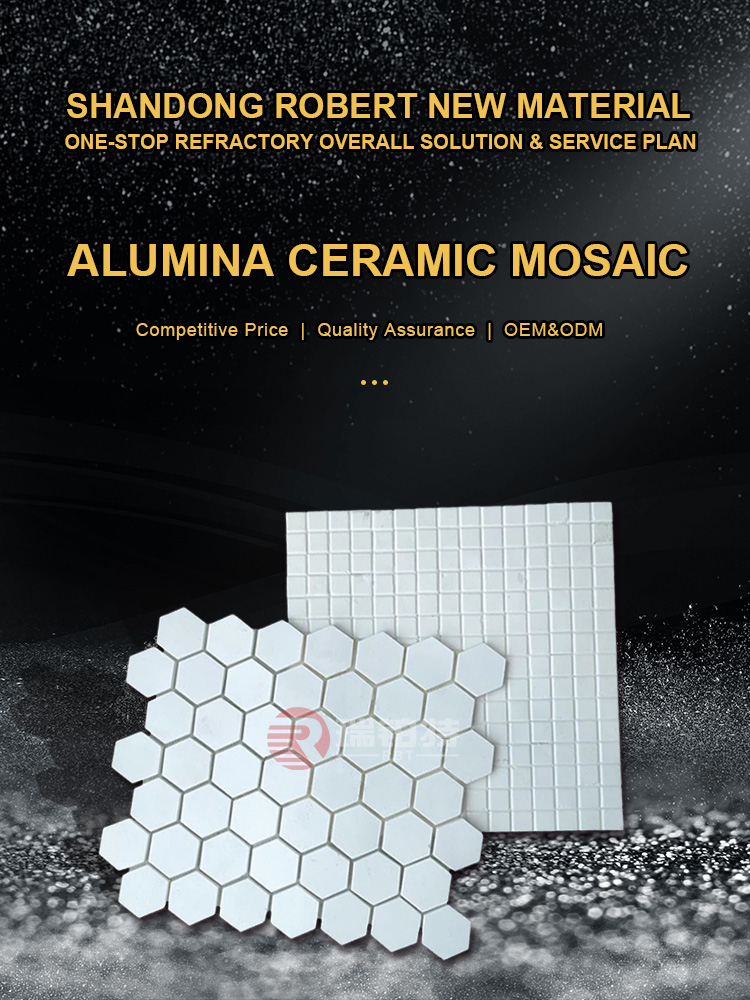

Alumina Ceramic Mosaic Tiles

Product Description

Alumina ceramic mosaic is a wear-resistant ceramic material made of alumina as the main raw material, through high-pressure molding and high-temperature sintering. Its main component is alumina, and rare metal oxides are added as flux, and it is sintered at a high temperature of 1,700 degrees.

Features:

High hardness: The Rockwell hardness of alumina ceramic mosaic reaches HRA80-90, second only to diamond, far exceeding the wear resistance of wear-resistant steel and stainless steel.

Strong wear resistance: Its wear resistance is equivalent to 266 times that of manganese steel and 171.5 times that of high-chromium cast iron, and it can perform well in high-frequency use occasions.

Corrosion resistance: It can effectively resist the erosion of highly corrosive media such as acids, alkalis, and salts, and maintain structural integrity and stable performance.

High temperature resistance: It can remain stable in high temperature environments without deformation or melting.

Light weight: The density is 3.6g/cm³, which is only half of that of steel, which can reduce the load on equipment.

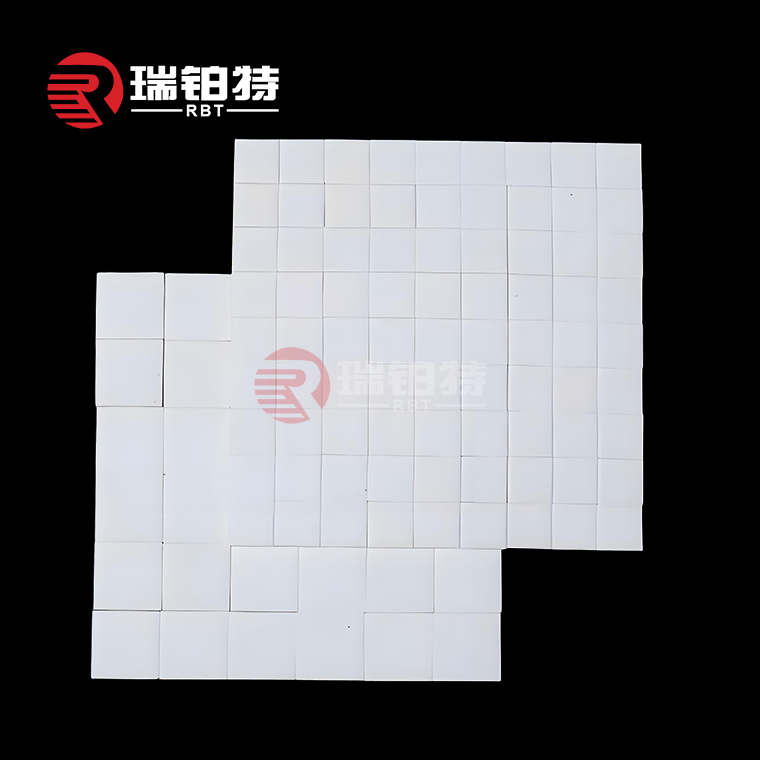

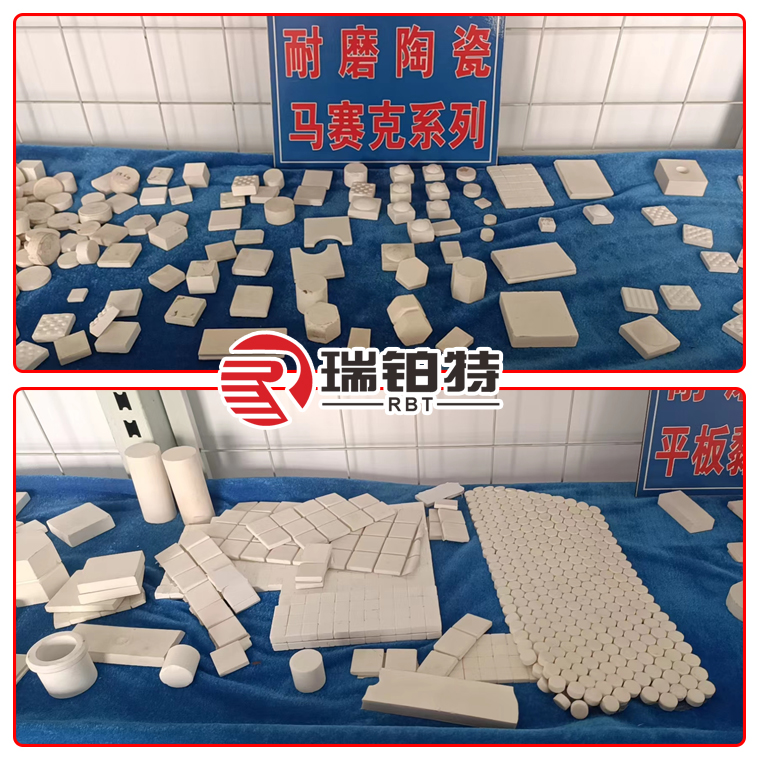

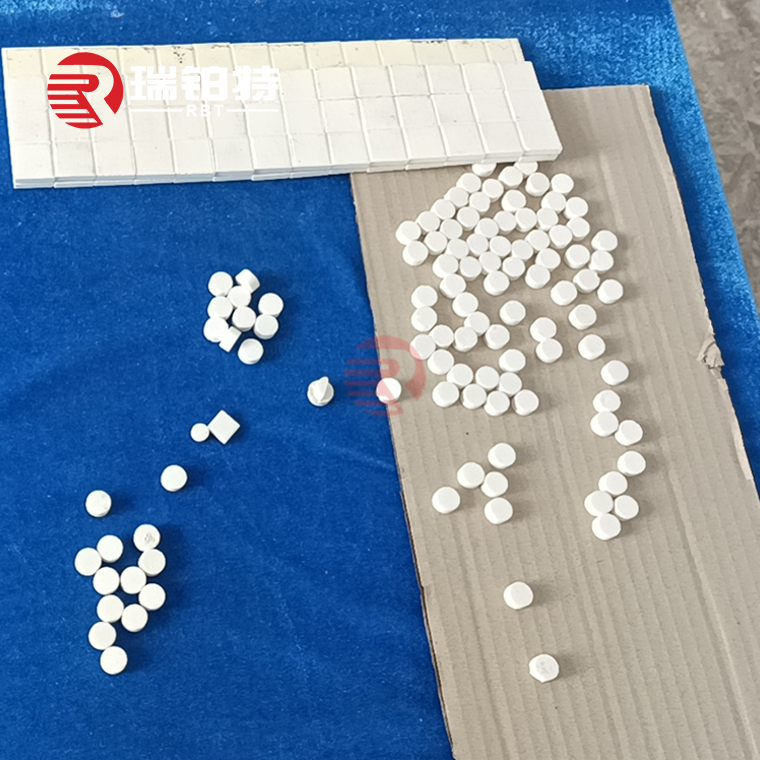

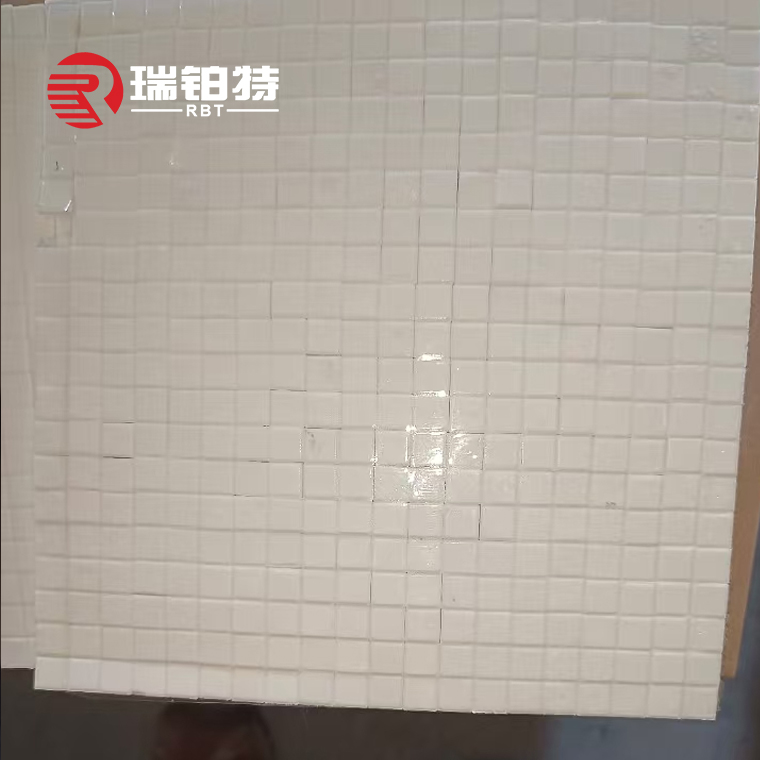

Details Images

The shapes of alumina ceramic mosaics mainly include square, circle and hexagon. The design of these shapes enables mosaic wear-resistant ceramics to better meet the needs of various special-shaped structural equipment. Through the design concept of straight instead of curved, it can better fit with the inner shell of the equipment, achieve gapless fitting, and meet the requirements of wear resistance in industrial production.

Product Index

|

Item

|

Al2O3 >92%

|

>95%

|

>99%

|

>99.5%

|

>99.7%

|

|

Color

|

White

|

White

|

White

|

Cream Color

|

Cream Color

|

|

Theoretical Density(g/cm3)

|

3.45

|

3.50

|

3.75

|

3.90

|

3.92

|

|

Bending Strength(Mpa)

|

340

|

300

|

330

|

390

|

390

|

|

Compressive Strength(Mpa)

|

3600

|

3400

|

2800

|

3900

|

3900

|

|

Elastic Modulus(Gpa)

|

350

|

350

|

370

|

390

|

390

|

|

Impact Resistance(Mpam1/2)

|

4.2

|

4

|

4.4

|

5.2

|

5.5

|

|

Weibull Coefficient(m)

|

11

|

10

|

10

|

12

|

12

|

|

Vickers Hardness(HV 0.5)

|

1700

|

1800

|

1800

|

2000

|

2000

|

|

Thermal Expansion Coefficient

|

5.0-8.3

|

5.0-8.3

|

5.1-8.3

|

5.5-8.4

|

5.5-8.5

|

|

Thermal Conductivity(W/mk)

|

18

|

24

|

25

|

28

|

30

|

|

Thermal Shock Stability

|

220

|

250

|

250

|

280

|

280

|

|

Maximum Operating Temperature℃

|

1500

|

1600

|

1600

|

1700

|

1700

|

|

20℃ Volume Resistance

|

>10^14

|

>10^14

|

>10^14

|

>10^15

|

>10^15

|

|

Dielectric Strength(kv/mm)

|

20

|

20

|

20

|

30

|

30

|

|

Dielectric Constant

|

10

|

10

|

10

|

10

|

10

|

Common Sizes

|

10*10*1.5

|

12*12*3

|

17.5*17.5*3

|

20*20*3

|

25*25*3

|

|

10*10*3

|

12*12*4

|

17.5*17.5*4

|

20*20*4

|

25*25*5

|

|

10*10*4

|

12*12*5

|

17.5*17.5*5

|

20*20*5

|

25*25*8

|

|

10*10*5

|

12*12*6

|

17.5*17.5*6

|

20*20*6

|

25*25*10

|

|

10*10*8

|

12*12*8

|

17.5*17.5*8

|

20*20*8

|

25*25*12

|

|

10*10*10

|

12*12*10

|

17.5*17.5*10

|

20*20*10

|

25*25*15

|

The above specifications are commonly used by our company. If you need other specifications, please consult customer service. The company can provide customization.

Applications

Industrial application: Widely used in coal transportation, material conveying systems, powder making systems, ash removal, dust removal systems, etc. in thermal power, steel, smelting, machinery, coal, mining, chemical, cement, port terminals and other enterprises.

Petrochemical: Used for lining and wear-resistant parts of equipment such as reactors, pipelines, pump bodies, etc., significantly extending the life of equipment and improving safety.

Mining and metallurgy: Used in wear parts of equipment such as ball mills, coal mills, and pulping machines to improve wear resistance and production efficiency. Power industry: Used in wear-resistant parts of coal-fired power generation and gas-fired power generation equipment, such as burners, coal mills, and dust collectors, to improve equipment life and operating efficiency.

Machinery manufacturing: Used to manufacture high-precision, high-wear-resistant parts such as bearings, gears, and guide rails to improve the performance and reliability of mechanical products.

Installation And Maintenance

Installation method: Usually fixed with professional adhesives. Before installation, ensure that the base layer is flat and dry to improve the bonding effect.

Maintenance method: For daily cleaning, use neutral detergent and soft cloth to wipe, avoid using acidic or alkaline detergents to avoid damaging the surface of the patch.

Coal and Material Conveying System

Pipe Lining

Ball Mill

Coal Mill

Dust Removal System

Machinery Manufacturing

More Photos

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.