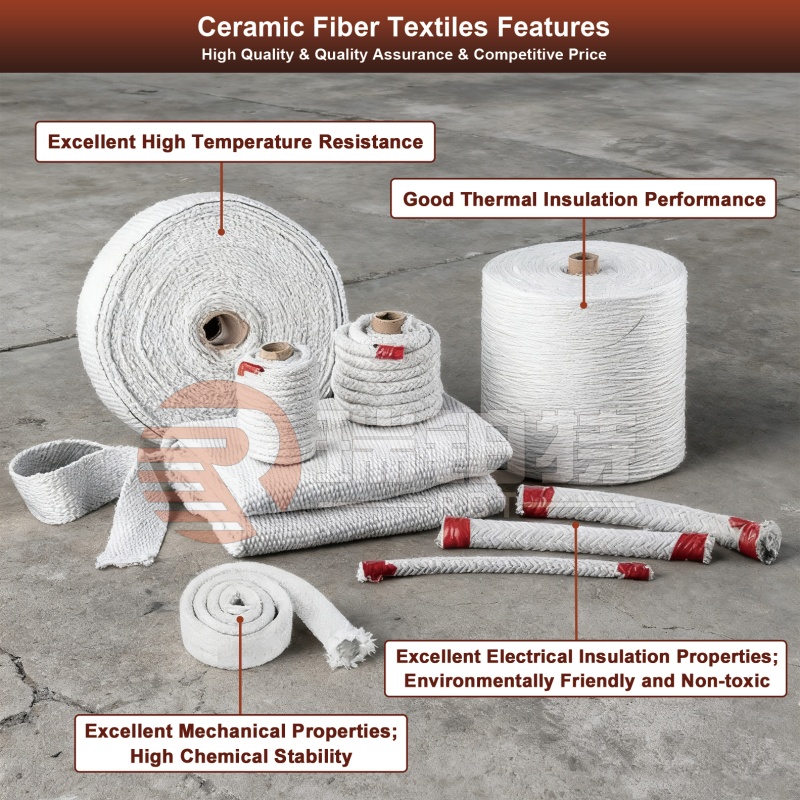

Ceramic Fiber Rope

Product Information

Ceramic fiber rope is typically made from high-purity alumina-silica ceramic fibers through a special process. It can be classified by structure into round braided rope, square braided rope, and twisted rope, and by reinforcement material into glass fiber reinforced and stainless steel wire reinforced types.

Main Characteristics:

(1) High Temperature Resistance: Ceramic fiber rope can withstand continuous use temperatures up to 1000℃ and short-term use temperatures up to 1260℃, maintaining stable performance even under high-temperature conditions for extended periods.

(2) Good Chemical Stability: Except for hydrofluoric acid, phosphoric acid, and strong alkalis, ceramic fiber rope is unaffected by most other chemicals and can be used in various chemical environments.

(3) Low Thermal Conductivity: It has excellent thermal insulation properties, effectively preventing heat transfer and reducing heat loss, protecting the surrounding environment and equipment.

(4) Moderate Tensile Strength: Ordinary ceramic fiber rope has a certain tensile strength to meet general usage requirements, while reinforced ceramic fiber rope, with the addition of metal or glass fiber filaments, has even stronger tensile strength.

Technical parameters: The bulk density of ceramic fiber rope is generally 300-500 kg/m³, the organic content is ≤15%, and the diameter is usually 3-50 mm.

Product Index

|

INDEX

|

Stainless Steel Wire Reinforced

|

Glass Filament Reinforced

|

|

Classification Temperature(℃)

|

1260

|

1260

|

|

Melting Point(℃)

|

1760

|

1760

|

|

Bulk Density(kg/m3)

|

350-600

|

350-600

|

|

Thermal Conductivity(W/m.k)

|

0.17

|

0.17

|

|

Lgnition Loss(%)

|

5-10

|

5-10

|

|

Chemical Composition

|

||

|

Al2O3(%)

|

46.6

|

46.6

|

|

Al2O3+Sio2

|

99.4

|

99.4

|

|

Standard Size(mm)

|

||

|

Fiber Cloth

|

Width: 1000-1500, Thickness: 2,3,5,6

|

|

|

Fiber Tape

|

Width: 10-150, Thickness: 2,2.5,3,5,6,8,10

|

|

|

Fiber Twisted Rope

|

Diameter: 3,4,5,6,8,10,12,14,15,16,18,20,25,30,35,40,50

|

|

|

Fiber Round Rope

|

Diameter: 5,6,8,10,12,14,15,16,18,20,25,30,35,40,45,50

|

|

|

Fiber Square Rope

|

5*5,6*6,8*8,10*10,12*12,14*14,15*15,16*16,18*18,20*20,25*25,

30*30,35*35,40*40,45*45,50*50

|

|

|

Fiber Sleeve

|

Diameter: 10,12,14,15,16,18,20,25mm

|

|

|

Fiber Yarn

|

Tex: 525,630,700,830,1000,2000,2500

|

|

Application

1. Industrial Kilns and High-Temperature Equipment:

Used for sealing industrial furnace doors, furnace chambers, and boiler flues to prevent high-temperature gas leakage and heat loss; suitable for high-temperature kilns in the ceramics, glass, and steel industries.

As a filling material for kiln pushers and furnace body expansion joints, it buffers deformation caused by thermal expansion and contraction, ensuring equipment stability.

Suitable for sealing and insulation of waste incinerators and hot blast stoves, withstanding long-term high-temperature conditions and not easily aging.

2. Pipeline and Mechanical Seal Applications:

Wrapped around high-temperature pipelines, valves, and flange connections, providing both sealing and insulation, reducing heat loss in pipelines; suitable for steam pipelines in the petrochemical and power industries.

Used as shaft seals in rotating machinery (such as fans and pumps), replacing traditional sealing materials under high-temperature, low-speed conditions, preventing lubricant leakage and withstanding equipment operating temperatures.

Filling gaps and holes in mechanical equipment to prevent high-temperature dust and gases from entering the equipment, protecting precision components.

3. Fire Protection and Construction:

As a fire-resistant sealing material for buildings, it fills gaps in cable trays and pipe penetrations through walls to prevent the spread of fire, suitable for high-rise buildings, power rooms, and other scenarios with high fire protection requirements.

It is used to manufacture sealing strips for fire curtains and fire doors, enhancing the sealing performance of fire-resistant components and extending fire separation time.

It is used as an auxiliary material for fire-resistant coating in steel structure buildings, wrapped around the surface of steel beams and columns, and works with fire-retardant coatings to improve heat insulation and delay the softening of steel at high temperatures.

4. Specialty Industry Applications:

Foundry Industry: Used for sealing ladles and furnace outlets to resist molten metal splashing and protect equipment interfaces from damage.

Petrochemical and Chemical Industries: Suitable for sealing and insulating reactors, burners, and pipelines, resistant to corrosion from strong acids and alkalis, and does not react with the media.

Aerospace: As a sealing and heat insulation material around spacecraft engines, it is suitable for short-term high-temperature impact environments, ensuring the safety of surrounding components.

New energy: Used for sealing high-temperature sintering furnaces and calcining furnaces in the photovoltaic and lithium battery industries to meet the high-temperature operating conditions required in clean energy production.

Industrial Furnaces and High-temperature Equipment

Petrochemical Industry

Automobiles

Fireproof and Heat Insulation

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.