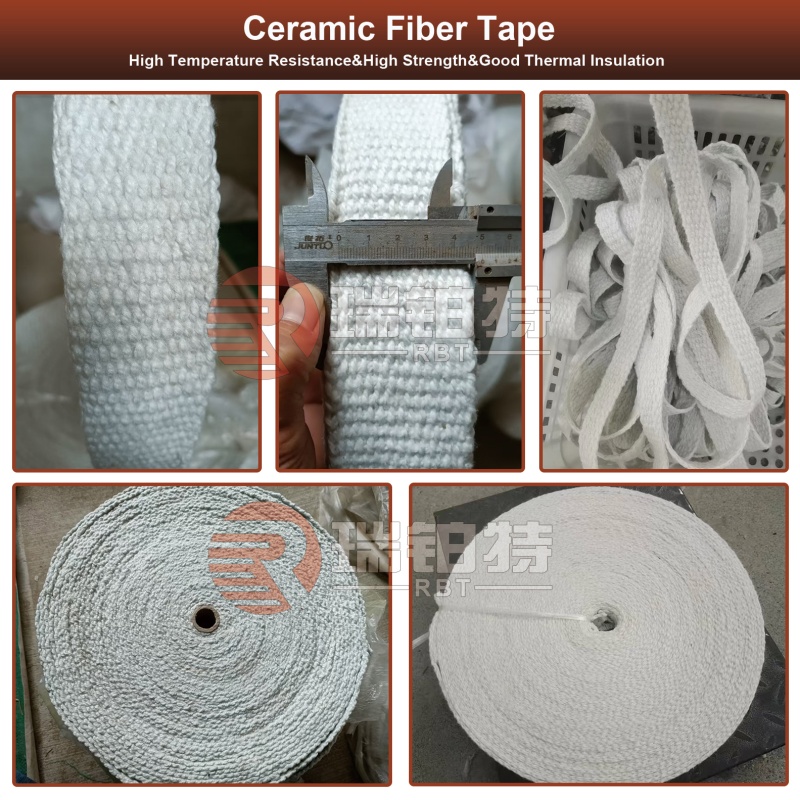

Ceramic Fiber Tape

Product Information

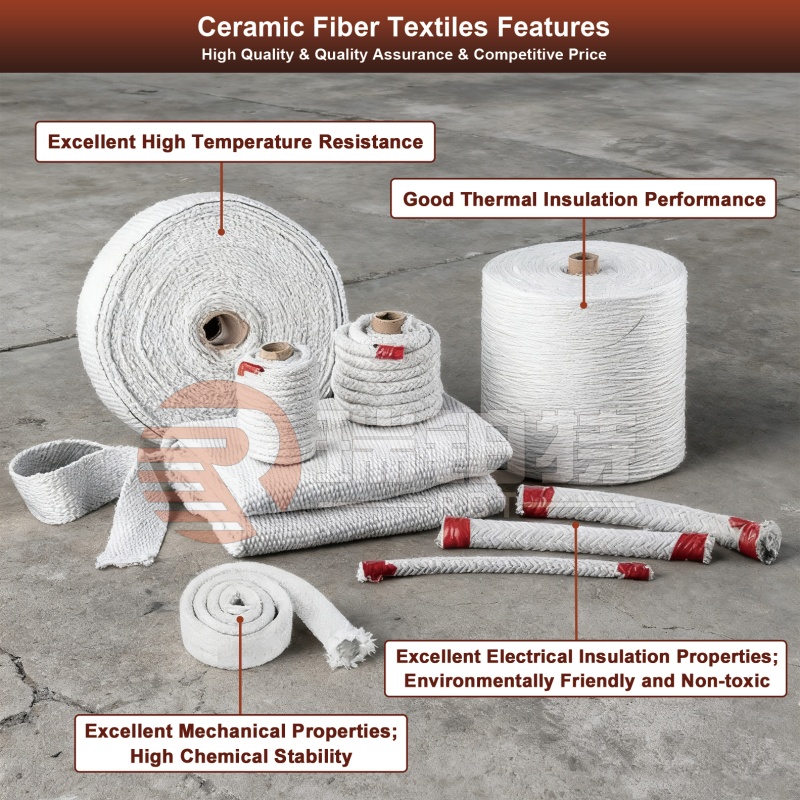

Ceramic fiber tape is a high-performance refractory and heat-insulating strip material made from ceramic fibers. Its core advantages are high temperature resistance, good flexibility, and strong sealing and insulation properties, making it suitable for winding and sealing needs in industrial and special applications.

Core Material and Structure:

The raw material is primarily high-purity alumina-silica ceramic fibers, with some products adding glass fibers or stainless steel wires to enhance tensile strength.

Form: Strip-shaped, typically 5-100mm wide and 1-10mm thick, customizable to meet specific needs. It has a smooth surface and excellent flexibility, facilitating winding and cutting.

Key Performance Characteristics:

(1) High Temperature Resistance: Continuous operating temperature up to 1000℃, short-term withstand of 1260℃, without melting or deformation at high temperatures.

(2) Heat Insulation and Sealing: Low thermal conductivity, effectively blocking heat transfer while providing excellent sealing performance, reducing gas leakage.

(3) Chemical Stability: Resistant to corrosion from most acid and alkali media (except hydrofluoric acid and strong alkalis), and not prone to aging or deterioration.

(4) Easy to process: It is highly flexible and can be directly wrapped, wrapped or cut into the required shape. It is easy to install and does not damage the surface of the equipment.

Product Index

|

INDEX

|

Stainless Steel Wire Reinforced

|

Glass Filament Reinforced

|

|

Classification Temperature(℃)

|

1260

|

1260

|

|

Melting Point(℃)

|

1760

|

1760

|

|

Bulk Density(kg/m3)

|

350-600

|

350-600

|

|

Thermal Conductivity(W/m.k)

|

0.17

|

0.17

|

|

Lgnition Loss(%)

|

5-10

|

5-10

|

|

Chemical Composition

|

||

|

Al2O3(%)

|

46.6

|

46.6

|

|

Al2O3+Sio2

|

99.4

|

99.4

|

|

Standard Size(mm)

|

||

|

Fiber Cloth

|

Width: 1000-1500, Thickness: 2,3,5,6

|

|

|

Fiber Tape

|

Width: 10-150, Thickness: 2,2.5,3,5,6,8,10

|

|

|

Fiber Twisted Rope

|

Diameter: 3,4,5,6,8,10,12,14,15,16,18,20,25,30,35,40,50

|

|

|

Fiber Round Rope

|

Diameter: 5,6,8,10,12,14,15,16,18,20,25,30,35,40,45,50

|

|

|

Fiber Square Rope

|

5*5,6*6,8*8,10*10,12*12,14*14,15*15,16*16,18*18,20*20,25*25,

30*30,35*35,40*40,45*45,50*50

|

|

|

Fiber Sleeve

|

Diameter: 10,12,14,15,16,18,20,25mm

|

|

|

Fiber Yarn

|

Tex: 525,630,700,830,1000,2000,2500

|

|

Application

Pipelines and Valves: Wrapped around high-temperature pipelines, valves, and flange connections, providing both sealing and insulation. Suitable for steam pipelines in the petrochemical and power industries.

Industrial Kilns: Used for sealing kiln door edges, filling furnace expansion joints, and providing external insulation for the furnace body. Suitable for ceramic, steel, and glass kilns.

Fireproofing: Fills gaps where building cables and pipes penetrate walls, or serves as a sealing strip for fire doors and fire curtains, slowing the spread of fire.

Specialty Applications: Used in the foundry industry for sealing ladle and furnace interfaces; in the aerospace and new energy fields as insulation material around high-temperature equipment.

Industrial Furnaces and High-temperature Equipment

Petrochemical Industry

Automobiles

Fireproof and Heat Insulation

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.