Magnesia Carbon Bricks

Magnesia carbon bricks are non-burning refractory materials made from high-temperature sintered magnesia or fused magnesia and carbon materials and various carbonaceous binders. Magnesia-carbon bricks maintain the advantages of carbon refractory materials and at the same time It has completely changed the inherent shortcomings of previous alkaline refractory materials such as poor spalling resistance and easy absorption of slag.

Excellent High-temperature Resistance: Magnesia-carbon bricks can be used continuously at temperatures above 1200℃. With magnesium oxide as the main component, which has a melting point of up to 2800℃, the bricks maintain excellent stability in high-temperature environments.

Strong Slag Erosion Resistance: Magnesium oxide exhibits outstanding resistance to alkaline slag corrosion, while carbon has poor wettability with molten slag. The combination of these two components enables magnesia-carbon bricks to effectively resist slag erosion and penetration, with a much thinner penetration layer compared to traditional fired basic bricks.

Good Thermal Shock Resistance: Inherited from graphite’s excellent thermal shock resistance, magnesia-carbon bricks feature high thermal conductivity, low linear expansion coefficient and low elastic modulus, which prevent cracking under rapid heating and cooling conditions.

High Strength at Elevated Temperatures: Magnesia-carbon bricks possess good high-temperature strength and wear resistance. They can withstand mechanical stress and abrasion under high temperatures without easily suffering structural damage or spalling.

Superior Oxidation Resistance: The addition of antioxidants enables magnesia-carbon bricks to effectively resist oxidation in the air, thereby extending their service life.

|

INDEX

|

Al2O3

(%) ≥

|

MgO

(%) ≥

|

F.C

(%) ≥

|

Apparent Porosity

(%) ≤

|

Bulk Density

(g/cm3) ≥

|

Cold Crushing

Strength(MPa) ≥

|

|

RBTMT-8

|

―

|

80

|

8

|

5

|

3.10

|

45

|

|

RBTMT-10

|

―

|

80

|

10

|

5

|

3.05

|

40

|

|

RBTMT-12

|

―

|

80

|

12

|

4

|

3.00

|

40

|

|

RBTMT-14

|

―

|

75

|

14

|

3

|

2.95

|

35

|

|

RBTAMT-9

|

65

|

11

|

9

|

8

|

2.98

|

40

|

Steelmaking Industry: Mainly used for linings of converters, EAF hot spots, ladle slag lines, and refining furnace (LF/VD/VOD) linings.

Non-ferrous Metallurgy: Applied in smelting furnaces for copper, aluminum, and zinc, resisting corrosion from non-ferrous molten metals and slags.

Other High-temperature Fields: Suitable for cement rotary kiln transition zones, glass kiln regenerators, and petrochemical high-temperature reactor linings.

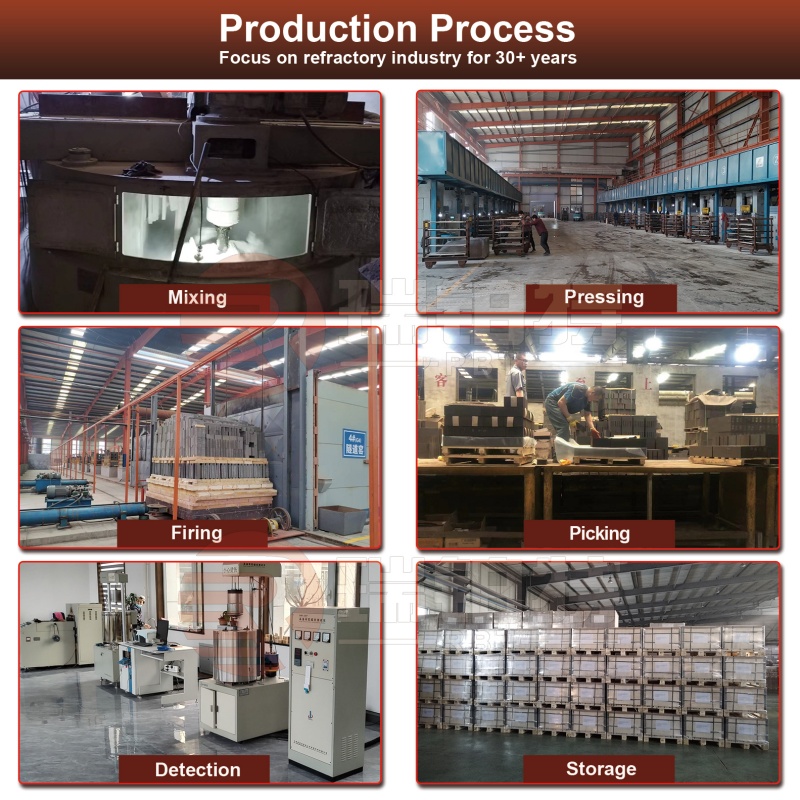

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.