Refractory Mortar

Product Information

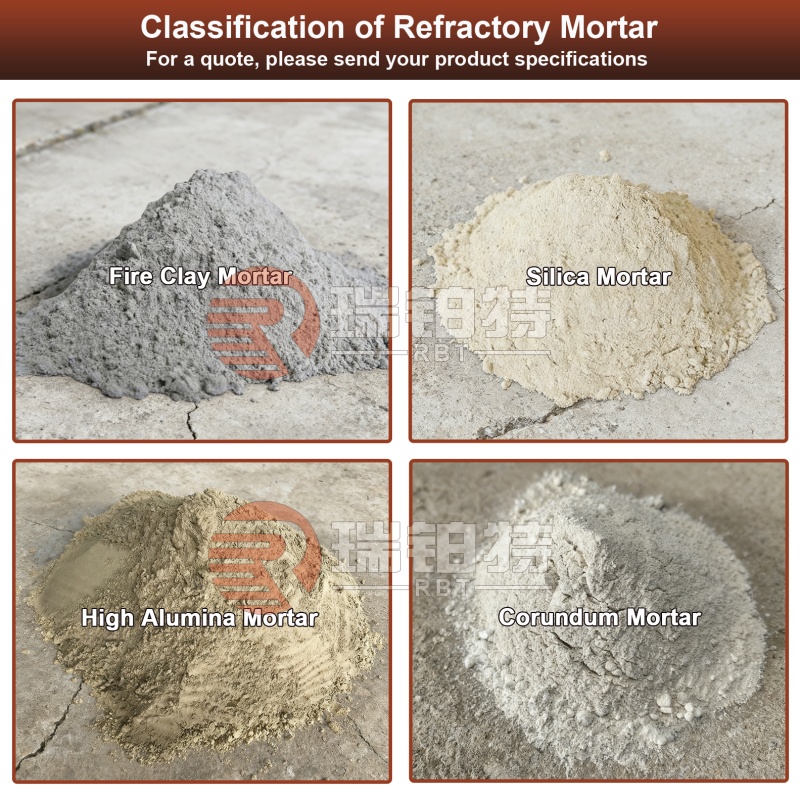

Refractory mortar, also known as fire mortar or joint material (powder), used as bonding refractory products brickwork materials, according to the material can be divided into clay, high aluminum, silicon and magnesium refractory mortar, etc.

It is called ordinary refractory mortar made of refractory clinker powder and plastic clay as binder and plastic agent. Its strength at room temperature is low, and the formation of ceramic bonding at high temperature has high strength. With hydraulicity, air hardening or thermo-hardening materials as binder, called chemical binding refractory mortar, as below the formation of ceramic binding temperature before the production of a certain chemical reaction and hardening.

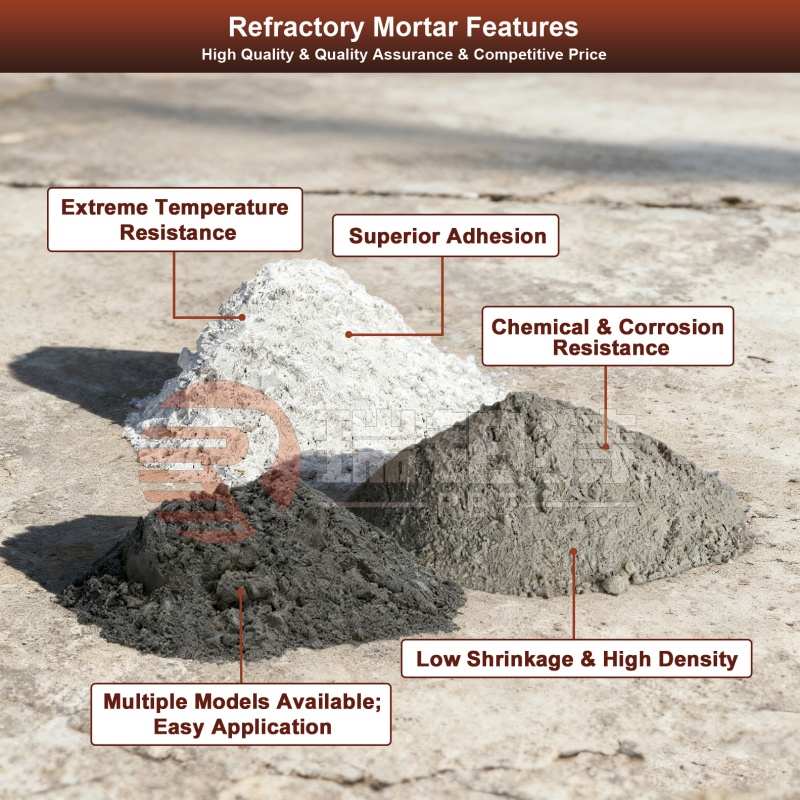

Refractory mortar characteristics: good plasticity, convenient construction; high bond strength, strong corrosion resistance; high refractoriness, up to 1650℃±50℃; good slag invasion resistance; good thermal spalling property.

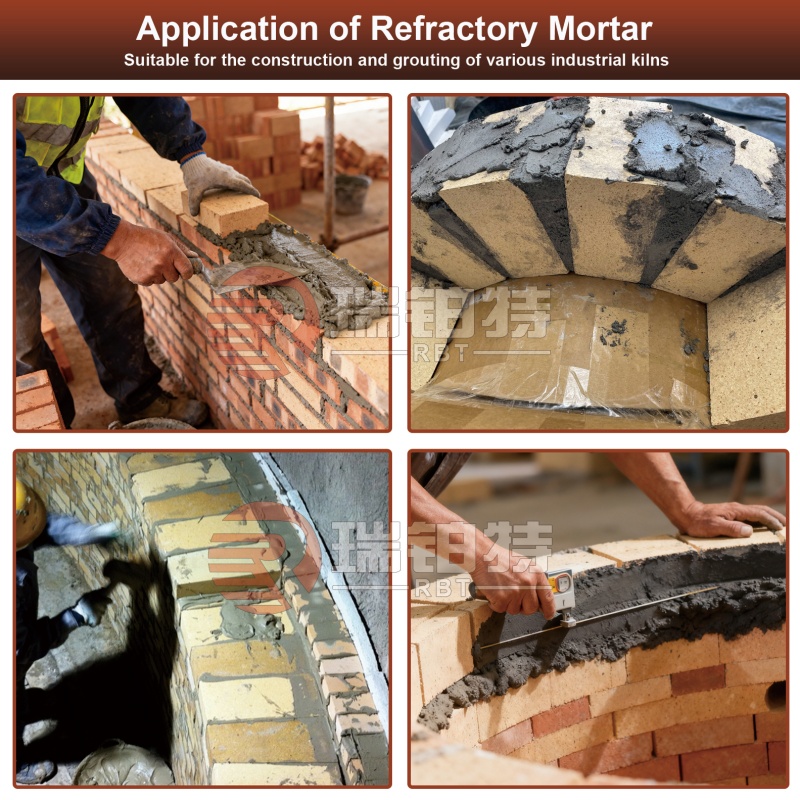

Refractory mortar is mainly used in coke oven, glass kiln, blast furnace, hot blast stove, metallurgy, architectural material industry, machinery, petrochemical, glass, boiler, electric power, iron and steel, cement and other industrial kiln.

Product Index

|

Index

|

Clay

|

High Alumina

|

||||

|

RBTMN-42

|

RBTMN-45

|

RBTMN-55

|

RBTMN-65

|

RBTMN-75

|

||

|

Refractorines(℃)

|

1700

|

1700

|

1720

|

1720

|

1750

|

|

|

CCS/MOR(MPa)≥

|

110℃×24h

|

1.0

|

1.0

|

2.0

|

2.0

|

2.0

|

|

1400℃×3h

|

3.0

|

3.0

|

4.0

|

4.0

|

4.0

|

|

|

Bonding Time(min)

|

1~2

|

1~2

|

1~2

|

1~2

|

1~2

|

|

|

Al2O3(%) ≥

|

42

|

45

|

55

|

65

|

75

|

|

|

SiO2(%) ≥

|

—

|

—

|

—

|

—

|

—

|

|

|

MgO(%) ≥

|

—

|

—

|

—

|

—

|

—

|

|

|

Index

|

Corundum

|

Silica

|

Lightweight

|

||

|

RBTMN-85

|

RBTMN-90

|

RBTMN-90

|

RBTMN-50

|

||

|

Refractorines(℃)

|

1800

|

1820

|

1670

|

|

|

|

CCS/MOR(MPa)≥

|

110℃×24h

|

2.0

|

2.0

|

1.0

|

0.5

|

|

1400℃×3h

|

3.5

|

3.0

|

3.0

|

1.0

|

|

|

Bonding Time(min)

|

1~3

|

1~3

|

1~2

|

1~2

|

|

|

Al2O3(%) ≥

|

85

|

90

|

—

|

50

|

|

|

SiO2(%) ≥

|

—

|

—

|

90

|

—

|

|

|

MgO(%) ≥

|

—

|

—

|

—

|

—

|

|

|

Index

|

Magnesia

|

|||

|

RBTMN-92

|

RBTMN-95

|

RBTMN-95

|

||

|

Refractorines(℃)

|

1790

|

1790

|

1820

|

|

|

CCS/MOR(MPa)≥

|

110℃×24h

|

1.0

|

1.0

|

1.0

|

|

1400℃×3h

|

3.0

|

3.0

|

3.0

|

|

|

Bonding Time(min)

|

1~3

|

1~3

|

1~3

|

|

|

Al2O3(%) ≥

|

—

|

—

|

—

|

|

|

SiO2(%) ≥

|

—

|

—

|

—

|

|

|

MgO(%) ≥

|

92

|

95

|

97

|

|

1. Clay-based Refractory Mortar

Core Applications: Suitable for laying clay-based refractory bricks in environments with temperatures ≤1350℃, such as low-temperature sections of industrial kilns, flues, chimneys, lower parts of hot blast stove regenerators, and boiler linings—all in low-corrosion, medium-to-low-temperature environments.

Features: Low cost, good workability, moderate resistance to rapid heating and cooling; not suitable for high-temperature molten slag/highly corrosive areas.

2. High-alumina refractory Mortar

Core applications: NM-50/NM-60: Suitable for high-alumina bricks (Al₂O₃ 55%~65%), used in the intermediate temperature section of kilns (1350~1500℃), such as ceramic kilns, metallurgical heating furnaces, and cement rotary kiln transition zones; NM-70/NM-75: Suitable for high-alumina bricks (Al₂O₃ ≥70%) or corundum bricks, used in the high-temperature section (1500~1700℃), such as blast furnace linings, steelmaking converter tapholes, glass kiln regenerators, and calcium carbide furnace linings.

Features: High refractoriness, superior slag resistance compared to clay-based slurries; the higher the Al₂O₃ content, the stronger the high-temperature resistance and erosion resistance.

3. Silica Refractory Mortar

Core Uses: Compatible with silica bricks, specifically designed for acidic conditions such as coke ovens, glass kiln walls/breast walls, and acidic steelmaking furnaces. Long-term operating temperature: 1600~1700℃.

Features: Resistant to acidic slag erosion; good thermal expansion compatibility with silica bricks, but poor alkali resistance; strictly prohibited for use in alkaline kilns.

4. Massica/Magnesium-chrome Refractory Mortar

Core Uses: Massica: Compatible with magnesia bricks; used in strongly alkaline slag conditions such as alkaline steelmaking converters, electric arc furnace hearts/walls, and non-ferrous metal smelting furnaces.

Magnesium-chrome: Compatible with magnesia-chrome bricks; used in high-temperature alkaline erosion scenarios such as cement rotary kiln firing zones, waste incinerators, and non-ferrous metal smelting furnaces.

Features: Extremely strong resistance to alkaline slag, but poor resistance to rapid heating and cooling; environmental compliance is required for magnesia-chrome refractory slurry (some regions restrict hexavalent chromium emissions).

5. Silicon carbide refractory mortar

Core applications: Suitable for silicon carbide bricks/silicon nitride-bonded silicon carbide bricks, used in high-temperature, wear-resistant, and reducing atmosphere applications such as blast furnace tapping troughs, steel ladle linings, coking furnace riser pipes, and secondary combustion chambers of waste incinerators.

Features: High thermal conductivity, high wear resistance, high-temperature oxidation resistance, and a service life far superior to traditional clay/high-alumina mortars.

6. Low-cement/cement-free refractory mortar

Core applications: Suitable for grouting/masonry of low-cement/cement-free castables or shaped refractory bricks, used for integral casting lining splicing of large industrial kilns and precision masonry of high-temperature kilns (such as glass kilns and metallurgical electric furnaces), with an operating temperature of 1400~1800℃.

Features: Low water content, high density and strength after sintering, no volume expansion problems caused by cement hydration, and excellent erosion resistance.

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.