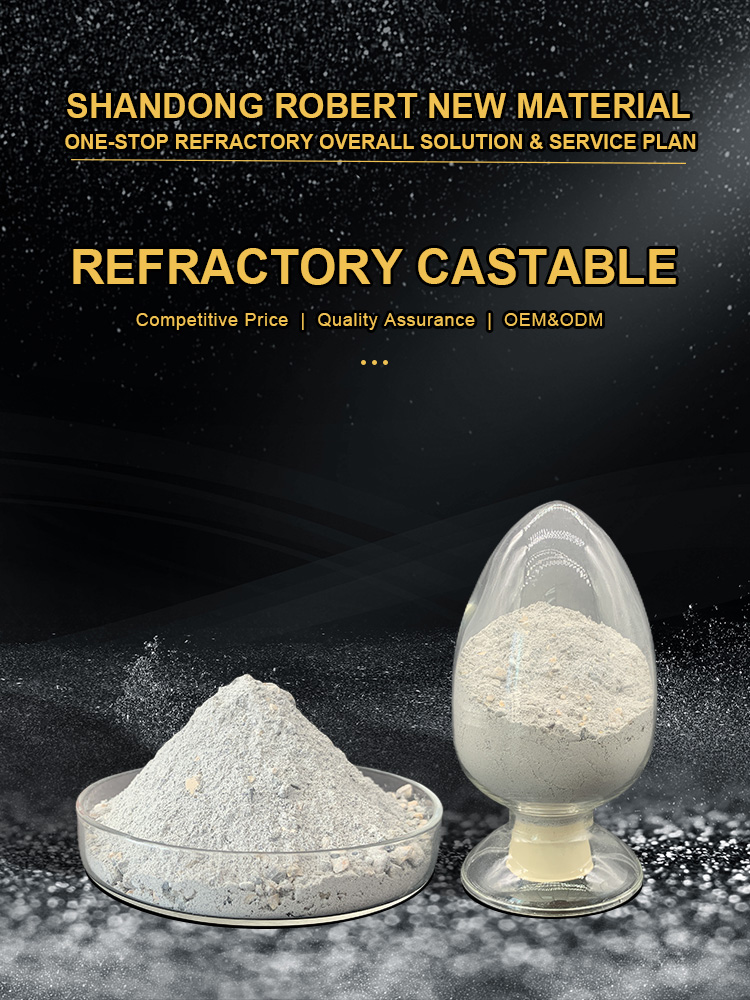

Refractory Castable&Concrete

Product Description

Refractory castables refer to a mixture of refractory aggregates, binders and admixtures, which are mixed with water (or liquid binders) to form a mud material that can be constructed by pouring. The difference from other amorphous refractory materials is that refractory castables have a certain coagulation and hardening time after construction, so after pouring and forming, they need to be cured for a certain period of time before demoulding, and then after a suitable period of natural curing, they can be put into baking and use.

Features

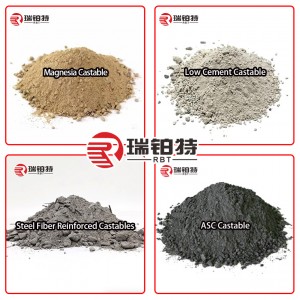

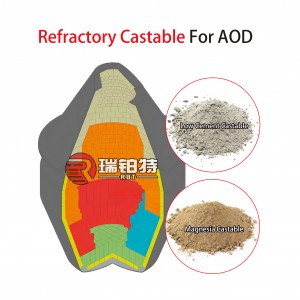

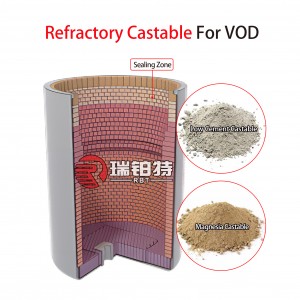

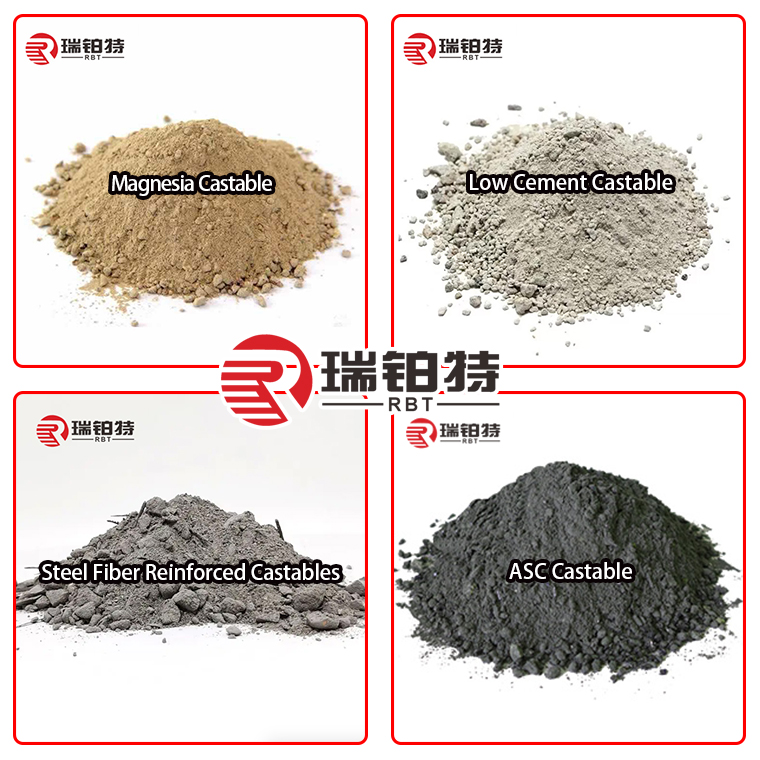

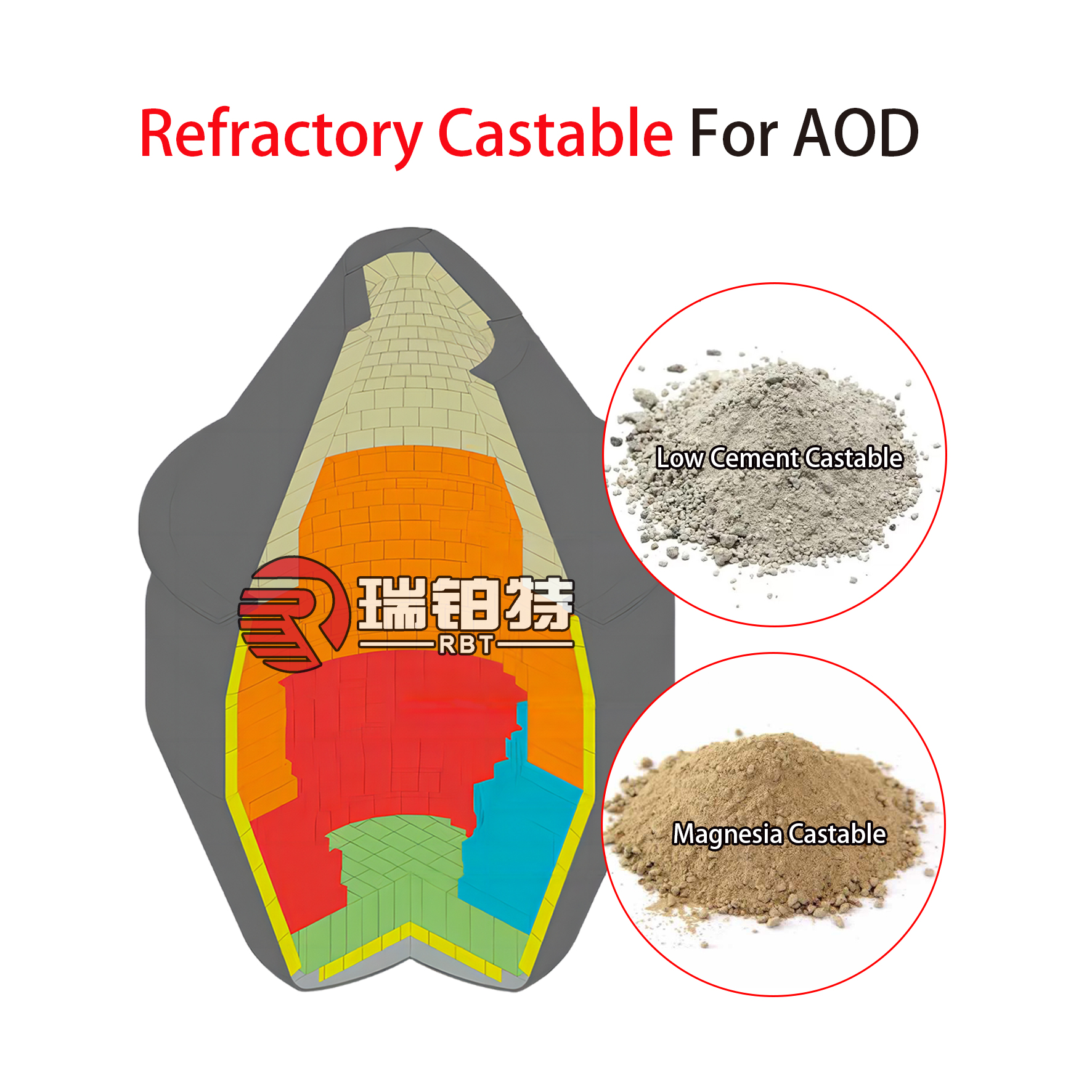

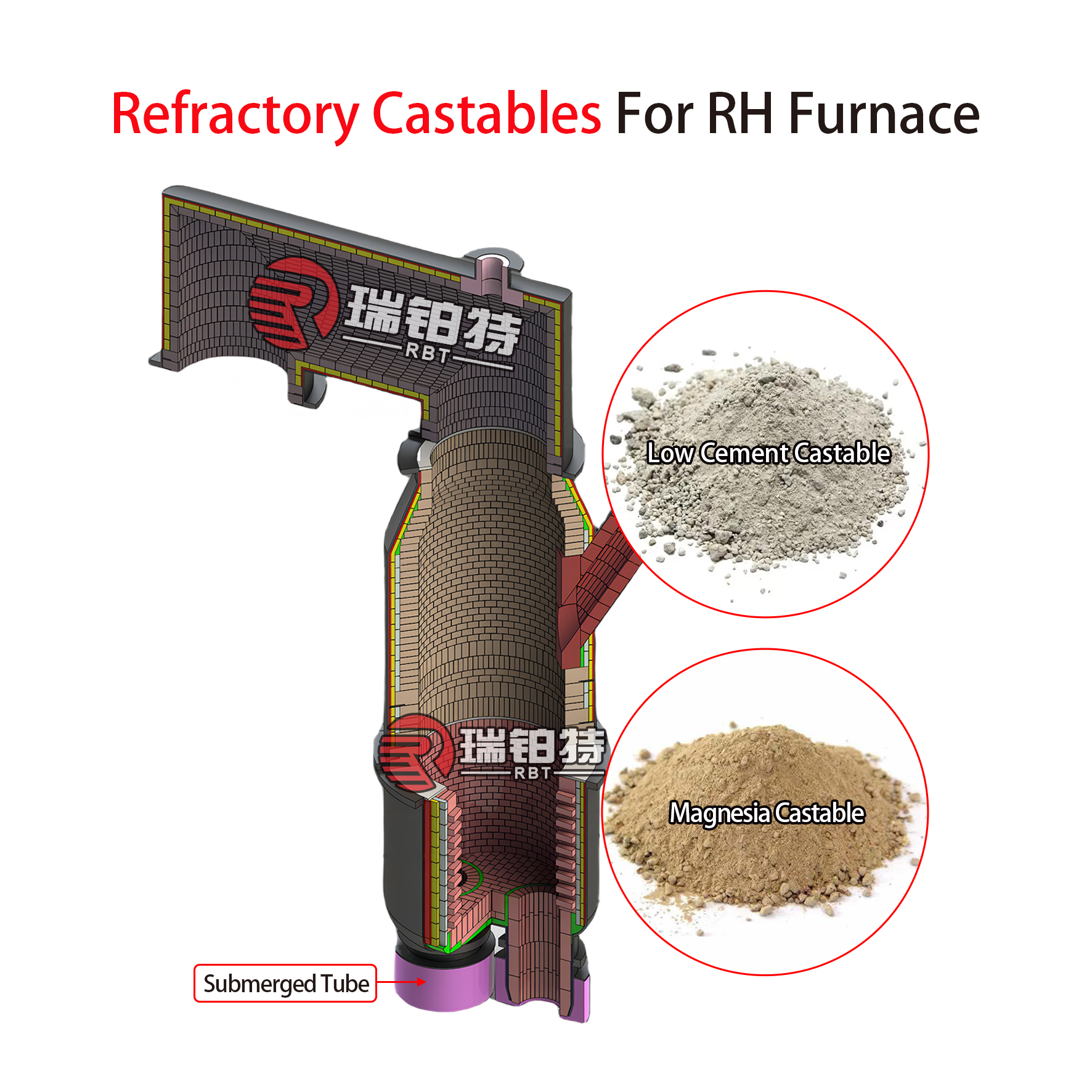

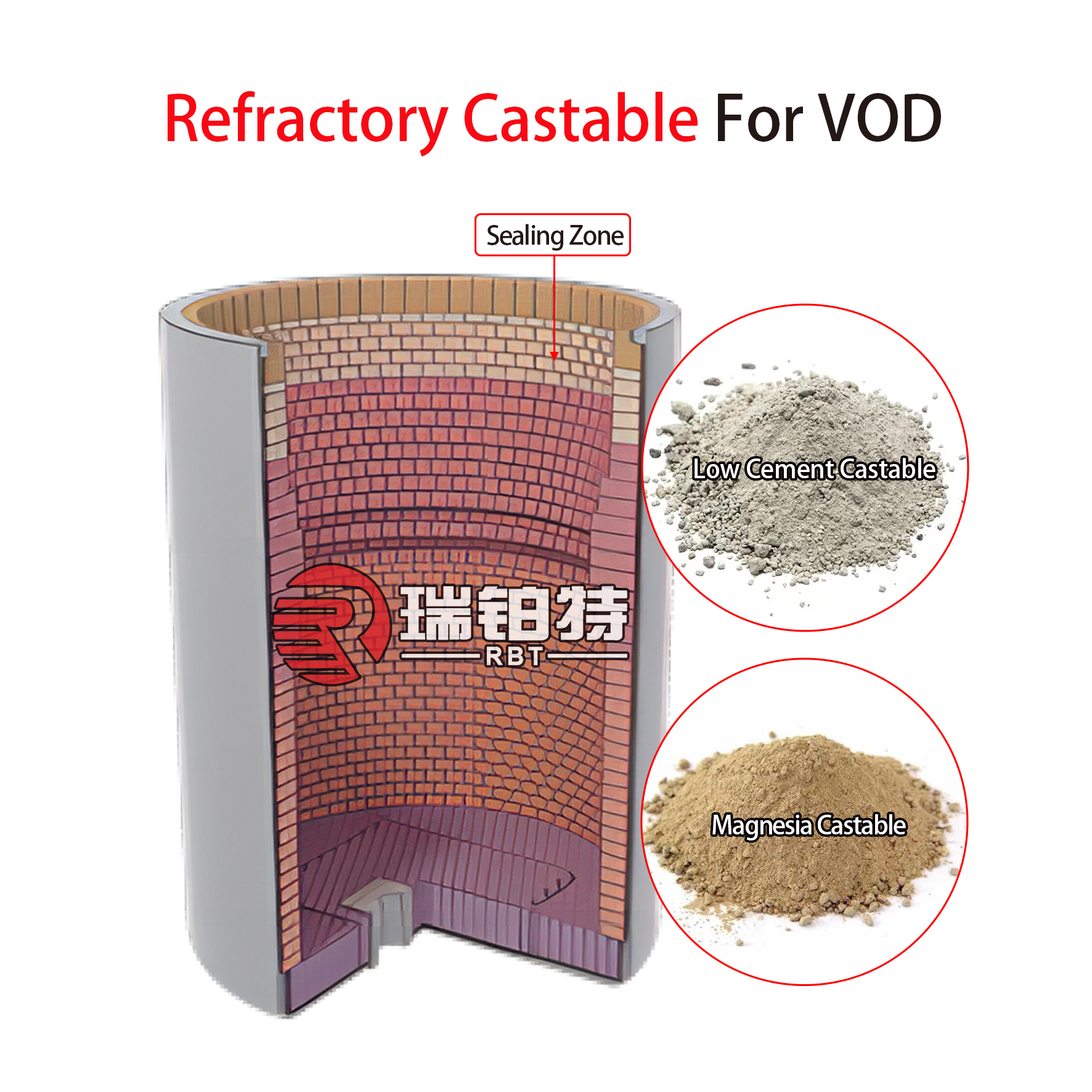

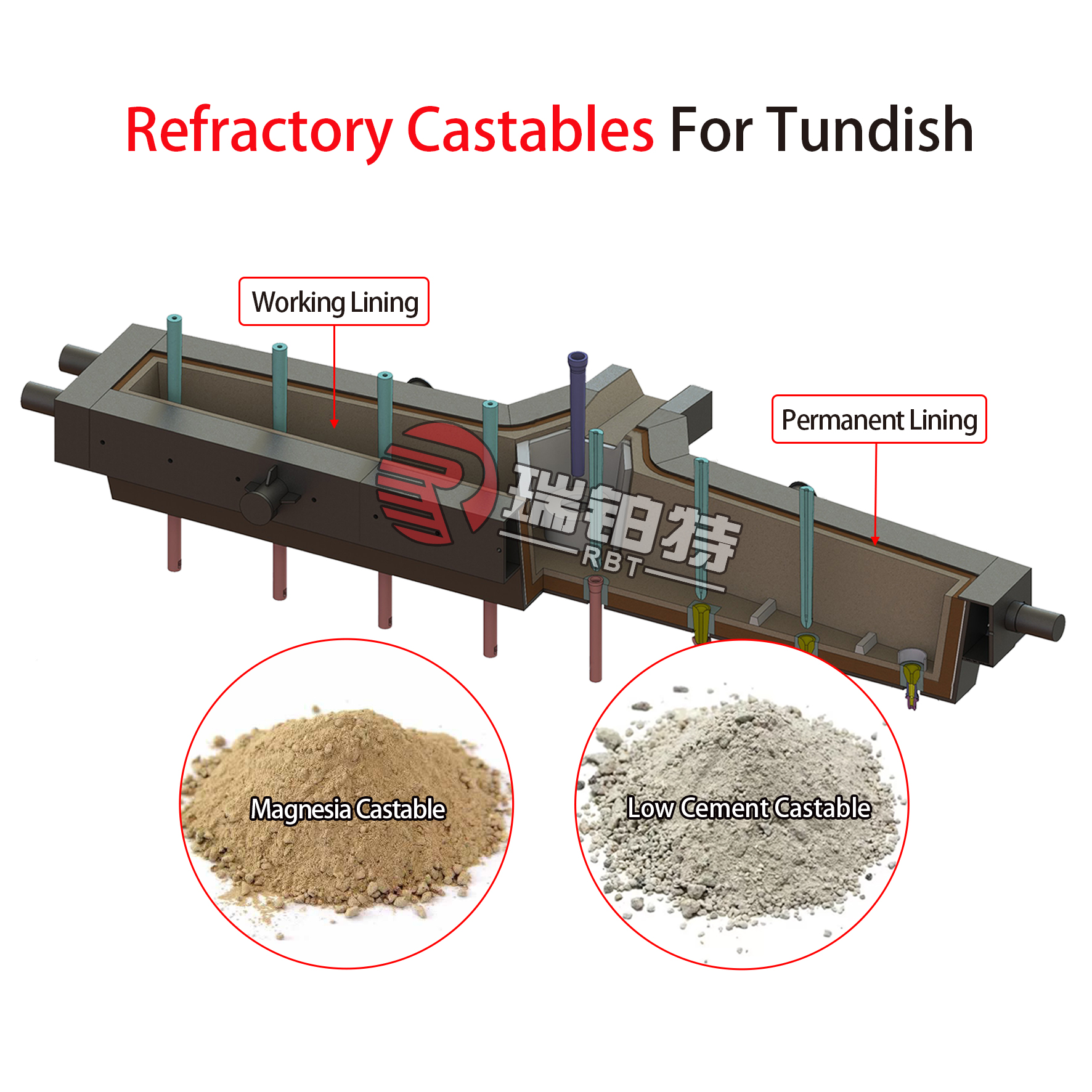

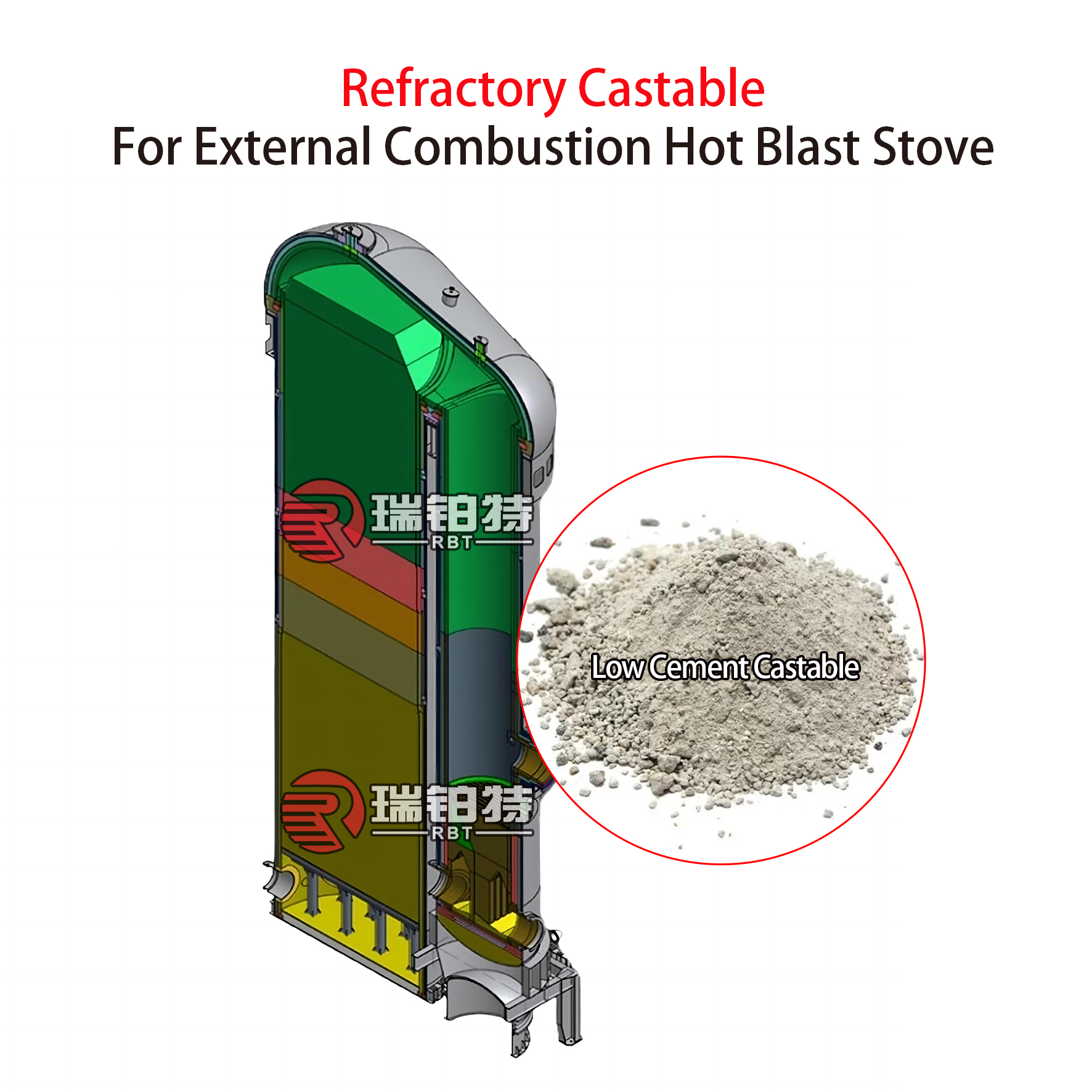

Low Cement Castable: Thermal shock resistance, slag resistance, and erosion resistance are significantly improved, surpassing similar refractory bricks.

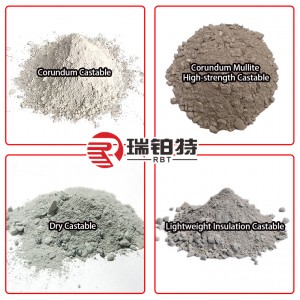

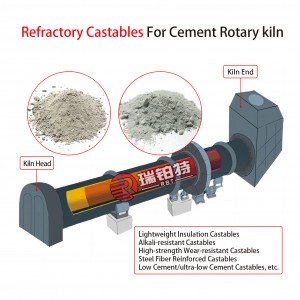

High Strength Castable: High strength, high wear resistance, impact resistance, erosion resistance, anti-oil permeability, arbitrary shape control, strong integrity, simple construction, good construction performance, and long service.

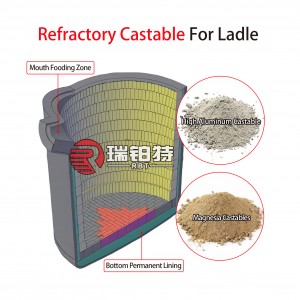

High Alumina Castable: Has high mechanical strength and good thermal shock resistance, abrasion resistance and other properties.

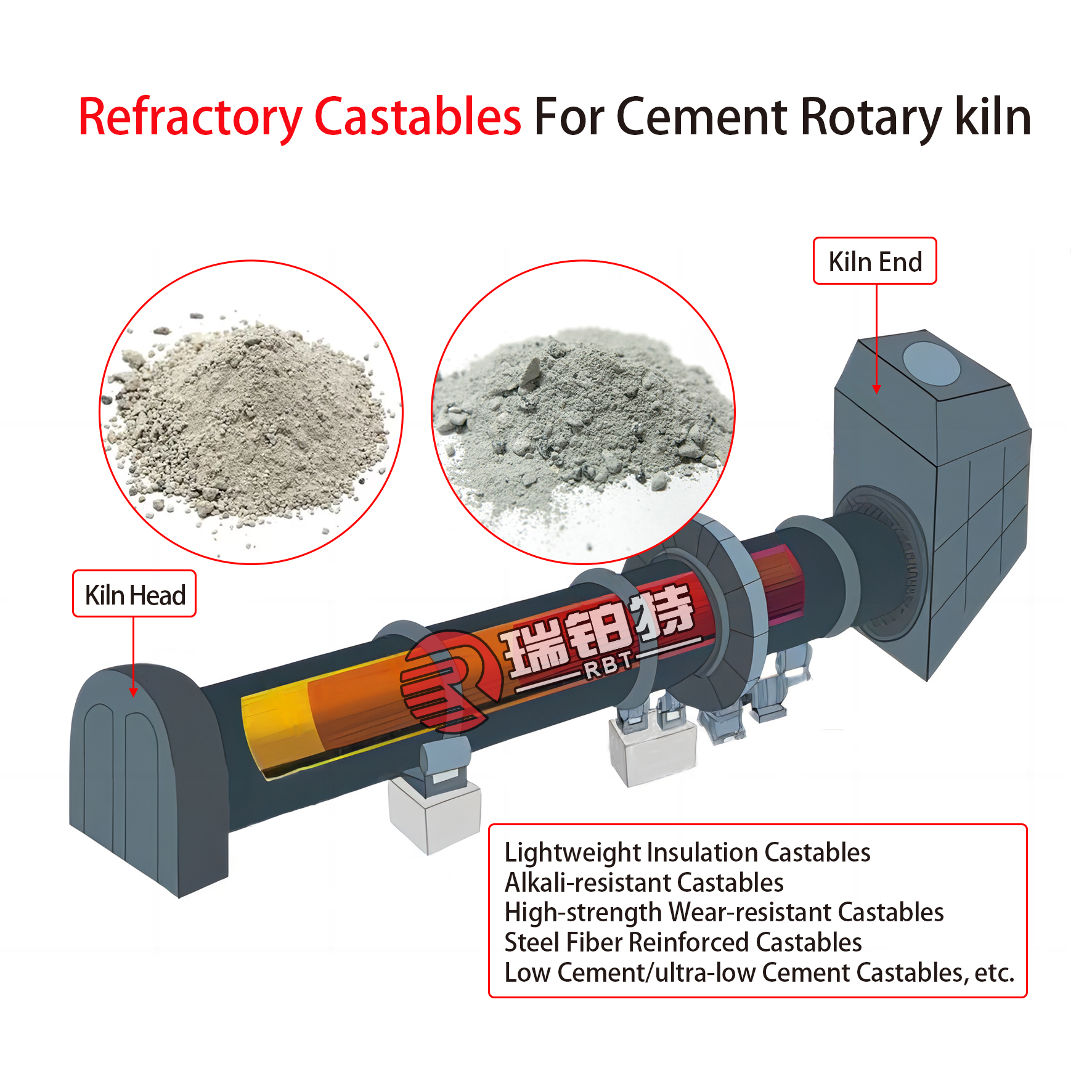

Lightweight Castable: Low bulk density, small thermal conductivity, good thermal insulation effect, high compressive strength, acid and acid gas corrosion resistance, heat insulation, thermal insulation, and low water absorption.

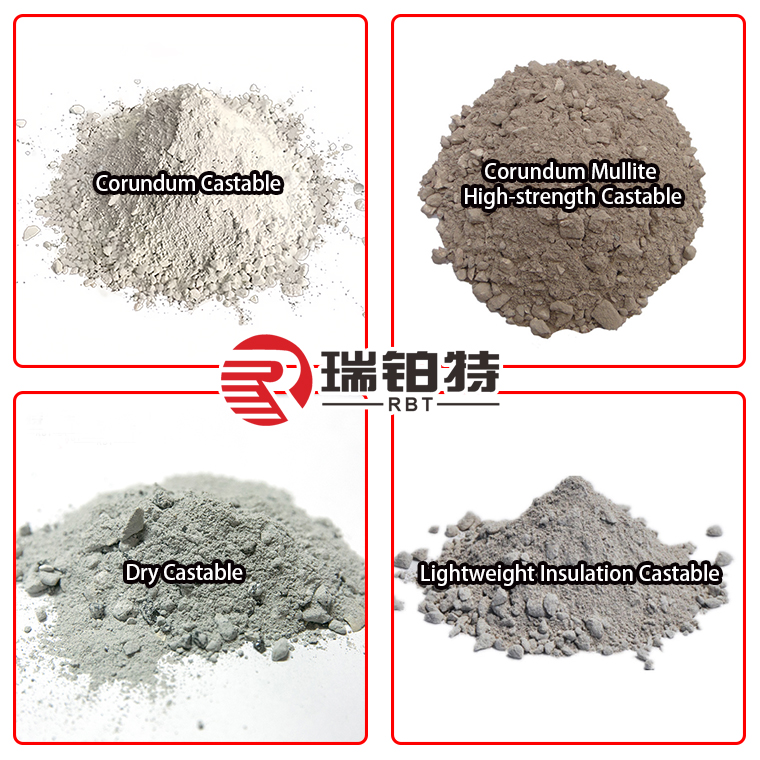

Details Images

Product Index

|

Product Name

|

Lightweight Castable

|

||||||

|

Working Limit Temperature

|

1100

|

1200

|

1400

|

1500

|

1600

|

||

|

110℃ Bulk Density(g/cm3) ≥

|

1.15

|

1.25

|

1.35

|

1.40

|

1.50

|

||

|

Modulus of Rupture(MPa) ≥

|

110℃×24h

|

2.5

|

3

|

3.3

|

3.5

|

3.0

|

|

|

1100℃×3h

|

2

|

2

|

2.5

|

3.5

|

3.0

|

||

|

1400℃×3h

|

―

|

―

|

3

|

10.8

|

8.1

|

||

|

Cold Crushing Strength(MPa) ≥

|

110℃×24h

|

8

|

8

|

11

|

12

|

10

|

|

|

1100℃×3h

|

4

|

4

|

5

|

11

|

10

|

||

|

1400℃×3h

|

―

|

―

|

15

|

22

|

14

|

||

|

Permanent Linear Change(%)

|

1100℃×3h

|

-0.65 1000℃×3h

|

-0.8

|

-0.25

|

-0.15

|

-0.1

|

|

|

1400℃×3h

|

―

|

―

|

-0.8

|

-0.55

|

-0.45

|

||

|

Thermal Conductivity(W/m.k)

|

350℃

|

0.18

|

0.20

|

0.30

|

0.48

|

0.52

|

|

|

700℃

|

0.25

|

0.25

|

0.45

|

0.61

|

0.64

|

||

|

Al2O3(%) ≥

|

33

|

35

|

45

|

55

|

65

|

||

|

Fe2O3(%) ≤

|

3.5

|

3.0

|

2.5

|

2.0

|

2.0

|

||

|

Product Name

|

Low Cement Castable

|

|||||

|

INDEX

|

RBTZJ

-42

|

RBTZJ

-60

|

RBTZJ

-65

|

RBTZJS

-65

|

RBTZJ

-70

|

|

|

Working Limit Temperature

|

1300

|

1350

|

1400

|

1400

|

1450

|

|

|

Bulk Density(g/cm3) 110℃×24h≥

|

2.15

|

2.3

|

2.4

|

2.4

|

2.45

|

|

|

Cold Bending Strength

110℃×24h(MPa) ≥

|

4

|

5

|

6

|

6

|

7

|

|

|

Cold Crushing Strength(MPa) ≥

|

110℃×24h

|

25

|

30

|

35

|

35

|

40

|

|

CT℃×3h

|

50

1300℃×3h

|

55

1350℃×3h

|

60

1400℃×3h

|

40

1400℃×3h

|

70

1400℃×3h

|

|

|

Permanent Linear Change

@CT℃ × 3h(%)

|

-0.5~+0.5

1300℃

|

-0.5~+0.5

1350℃

|

0~+0.8

1400℃

|

0~+0.8

1400℃

|

0~+1.0

1400℃

|

|

|

Thermal Shock Resistance

(1000℃water) ≥

|

―

|

―

|

―

|

20

|

―

|

|

|

Al2O3(%) ≥

|

42

|

60

|

65

|

65

|

70

|

|

|

CaO(%) ≤

|

2-3

|

2-3

|

2-3

|

2-3

|

2-3

|

|

|

Fe2O3(%) ≤

|

2.0

|

1.5

|

1.5

|

1.5

|

1.5

|

|

|

Product Name

|

High Strength Castable

|

|||||

|

INDEX

|

HS-50

|

HS-60

|

HS-70

|

HS-80

|

HS-90

|

|

|

Working Limit Temperature(℃)

|

1400

|

1500

|

1600

|

1700

|

1800

|

|

|

110℃ Bulk Density(g/cm3) ≥

|

2.15

|

2.30

|

2.40

|

2.50

|

2.90

|

|

|

Modulus of Rupture

(MPa) ≥

|

110℃×24h

|

6

|

8

|

8

|

8.5

|

10

|

|

1100℃×3h

|

8

|

8.5

|

8.5

|

9

|

9.5

|

|

|

1400℃×3h

|

8.5 1300℃×3h

|

9

|

9.5

|

10

|

15

|

|

|

Cold Crushing Strength(MPa)≥

|

110℃×24h

|

35

|

40

|

40

|

45

|

60

|

|

1100℃×3h

|

40

|

50

|

45

|

50

|

70

|

|

|

1400℃×3h

|

45 1300℃×3h

|

55

|

50

|

55

|

100

|

|

|

Permanent Linear Change(%)

|

1100℃×3h

|

-0.2

|

-0.2

|

-0.25

|

-0.15

|

-0.1

|

|

1400℃×3h

|

-0.45 1300℃×3h

|

-0.4

|

-0.3

|

-0.3

|

-0.1

|

|

|

Al2O3(%) ≥

|

48

|

48

|

55

|

65

|

75

|

90

|

|

CaO(%) ≤

|

4.0

|

4.0

|

4.0

|

4.0

|

4.0

|

4.0

|

|

Fe2O3(%) ≤

|

3.5

|

3.5

|

3.0

|

2.5

|

2.0

|

2.0

|

Application

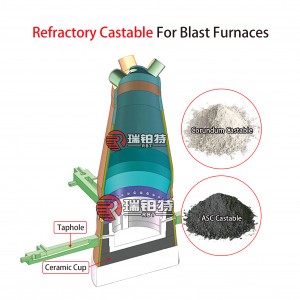

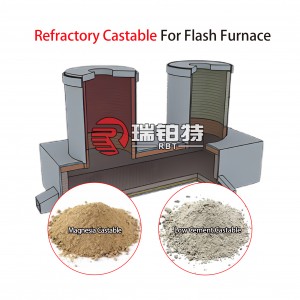

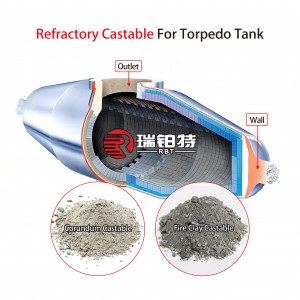

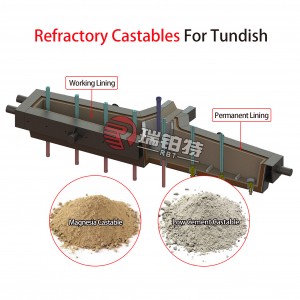

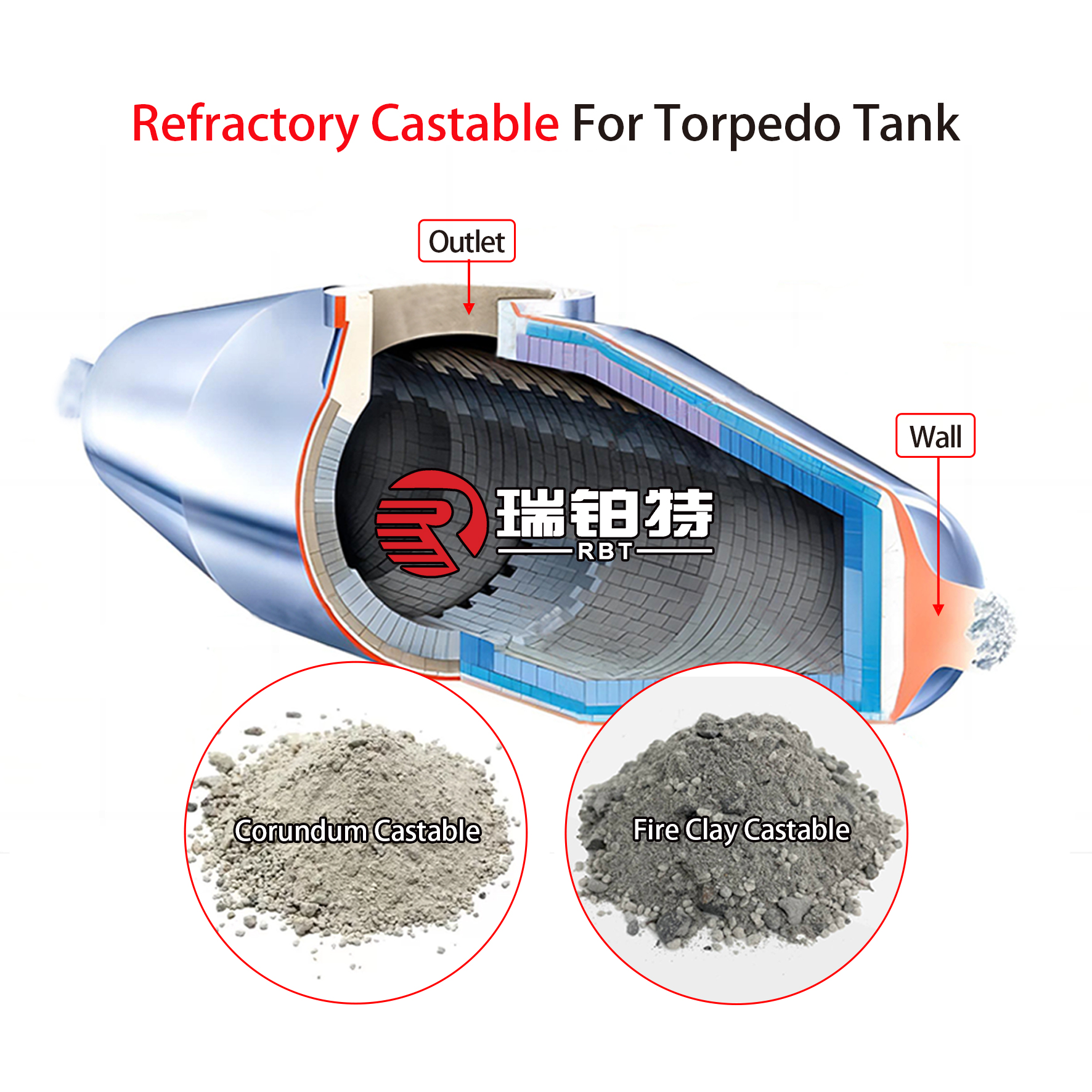

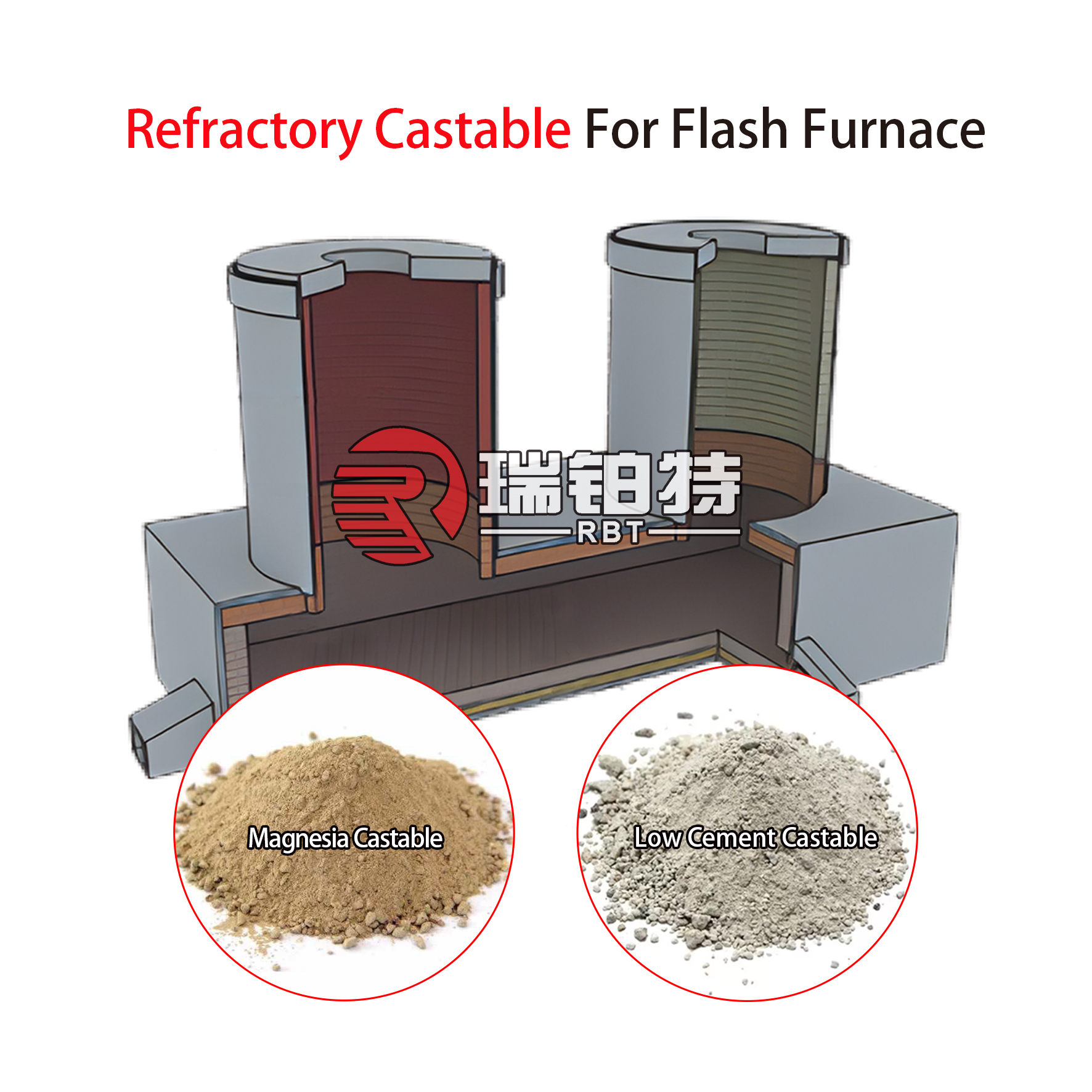

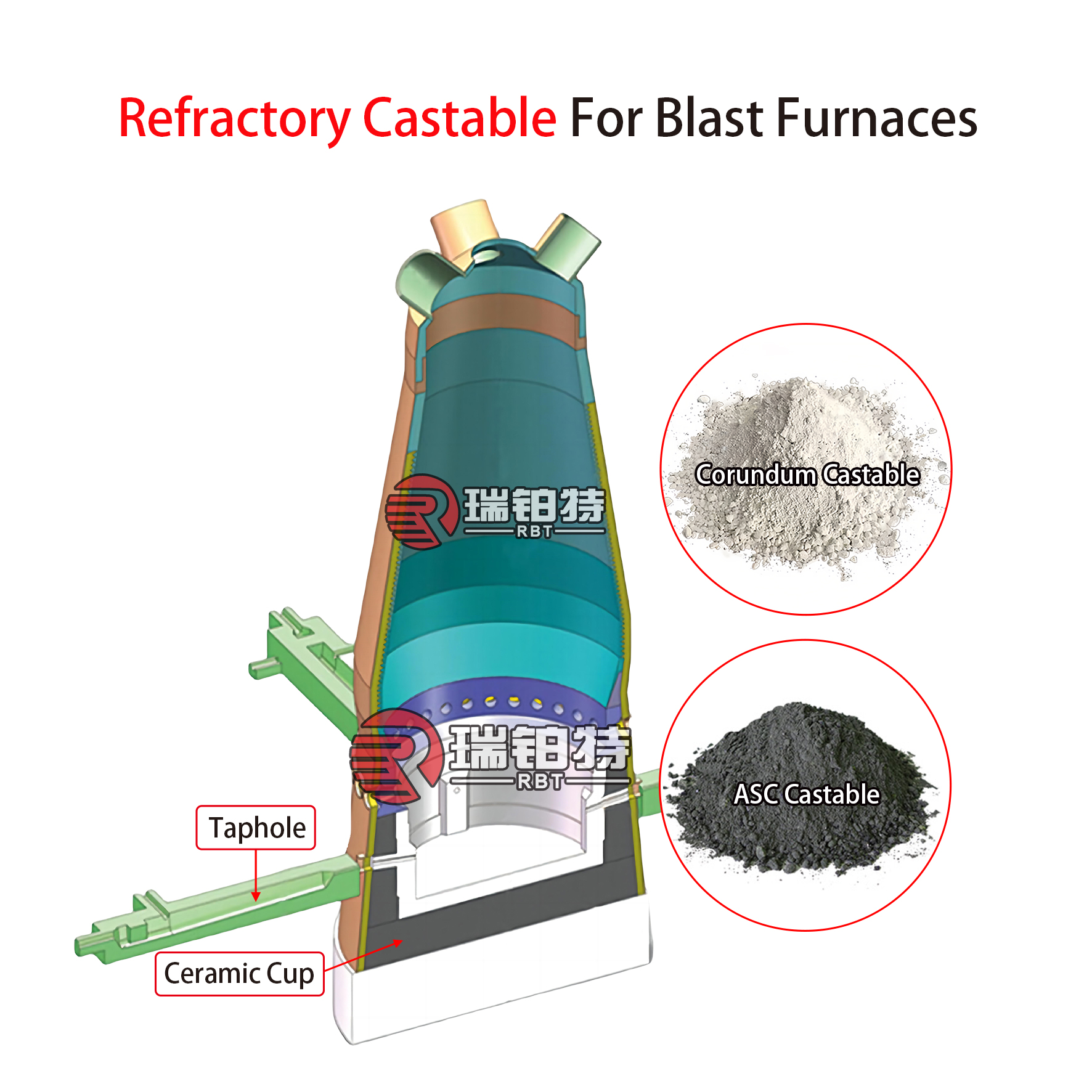

Iron and steel industry: Mainly used for maintenance and patching of electric arc furnaces, steelmaking furnaces, ladles and other equipment.

Non-ferrous metal industry: Used for patching and repairing of copper, aluminum, zinc, nickel and other non-ferrous metal smelting furnaces and converters.

Glass industry: Used for maintenance and patch work of glass furnaces, annealing furnaces and other equipment.

Building materials industry: Used for maintenance and patching of building materials production equipment such as cement rotary kiln and gypsum kiln.

Chemical industry: Used for maintenance and patching of high-temperature chemical equipment such as catalytic cracking furnaces and gasifiers.

Ceramic industry: Used for maintenance and repair of ceramic production equipment such as tunnel kiln and shuttle kiln.

Package&Warehouse

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Robert`s products are widely used in high-temperature kilns such as non-ferrous metals, steel, building materials and construction, chemical, electric power, waste incineration, and hazardous waste treatment. They are also used in steel and iron systems such as ladles, EAF, blast furnaces, converters, coke ovens, hot blast furnaces; non-ferrous metallurgical kilns such as reverberators, reduction furnaces, blast furnaces, and rotary kilns; building materials industrial kilns such as glass kilns, cement kilns, and ceramic kilns; other kilns such as boilers, waste incinerators, roasting furnace, which have achieved good results in using. Our products are exported to Southeast Asia, Central Asia, Middle East, Africa, Europe, Americas and other countries, and has established a good cooperation foundation with multiple well-known steel enterprises. All employees of Robert sincerely look forward to working with you for a win-win situation.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.