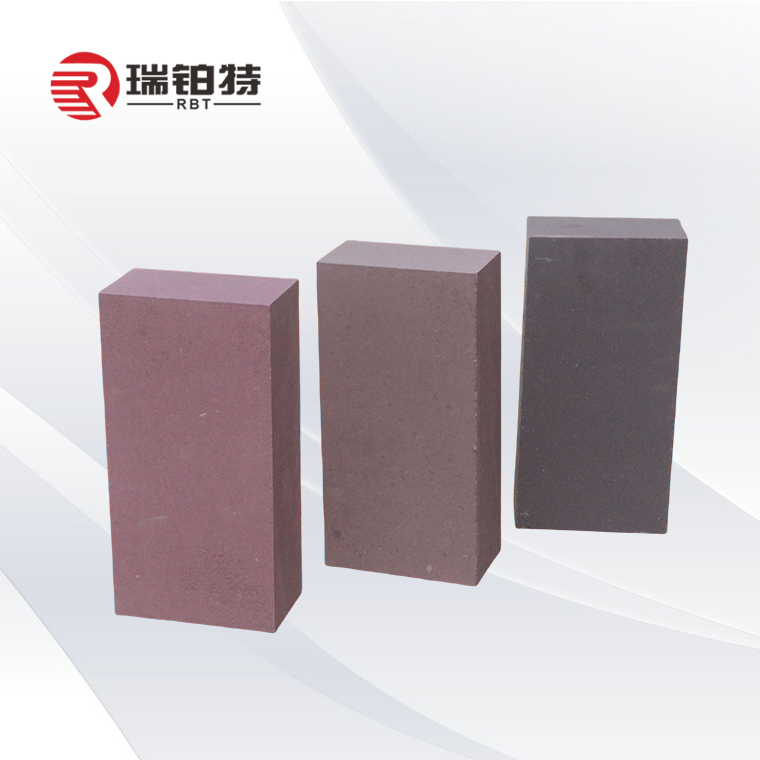

Corundum Bricks

Product Information

|

Product Name

|

Corundum Bricks

|

|

Description

|

Corundum bricks are a kind of aluminum-silicon refractory product with corundum as the main crystal phase. By adding some other chemical mineral components, it can form composite products.

|

|

Classification

|

Corundum Bricks; Zirconium Corundum Bricks, Chrome Corundum Bricks, Chrome Zirconium Corundum Bricks, etc.

|

|

Features

|

High melting point, good slag resistance, high strength and hardness, and abrasion resistance.

|

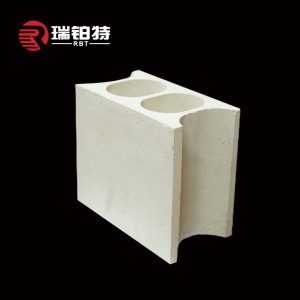

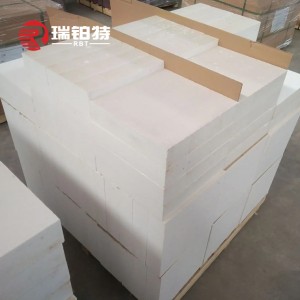

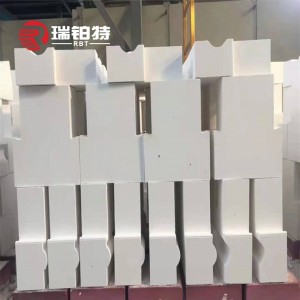

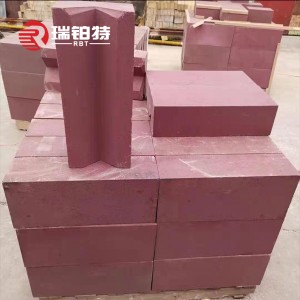

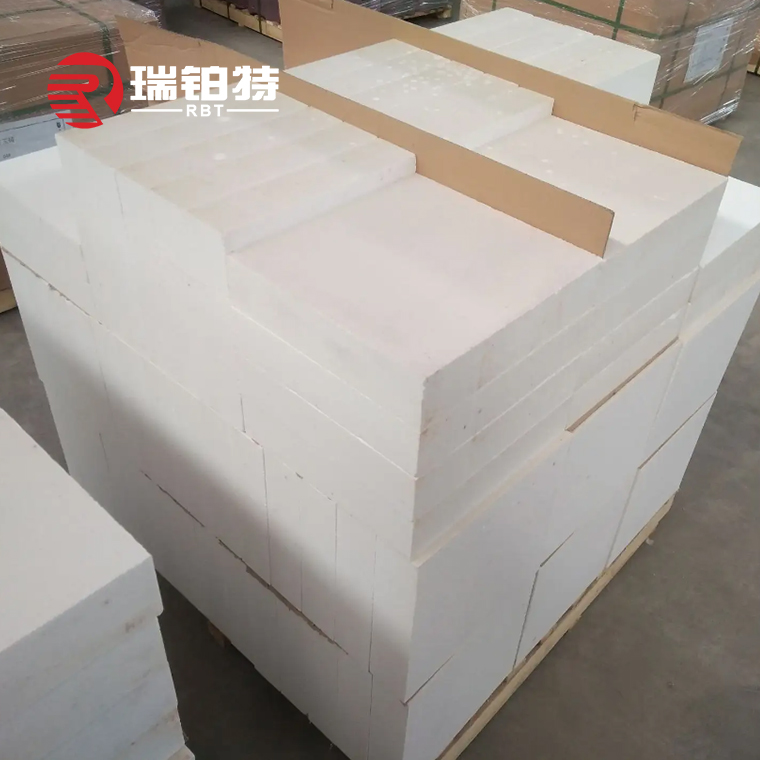

Details Images

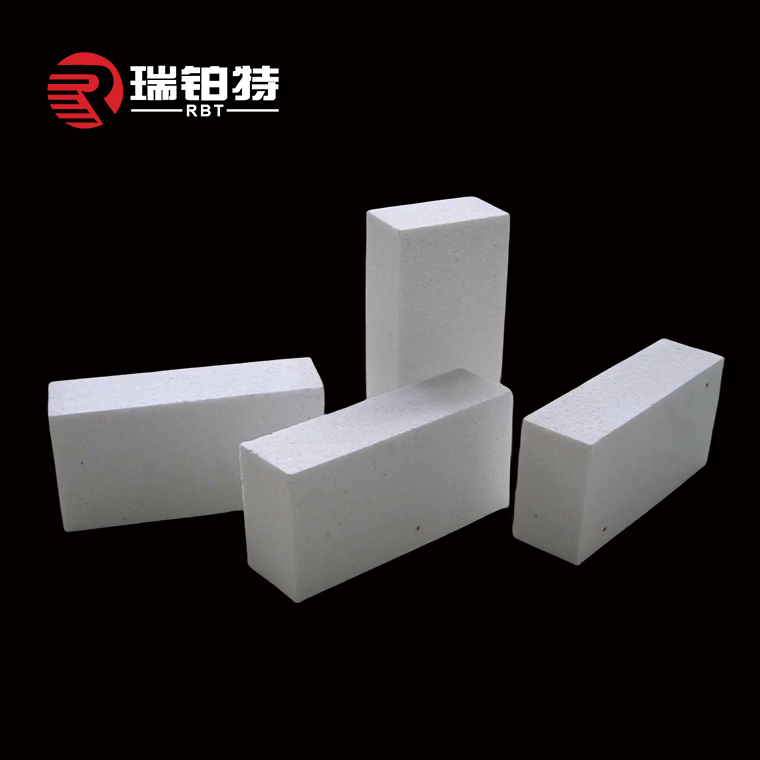

White Corundum Bricks

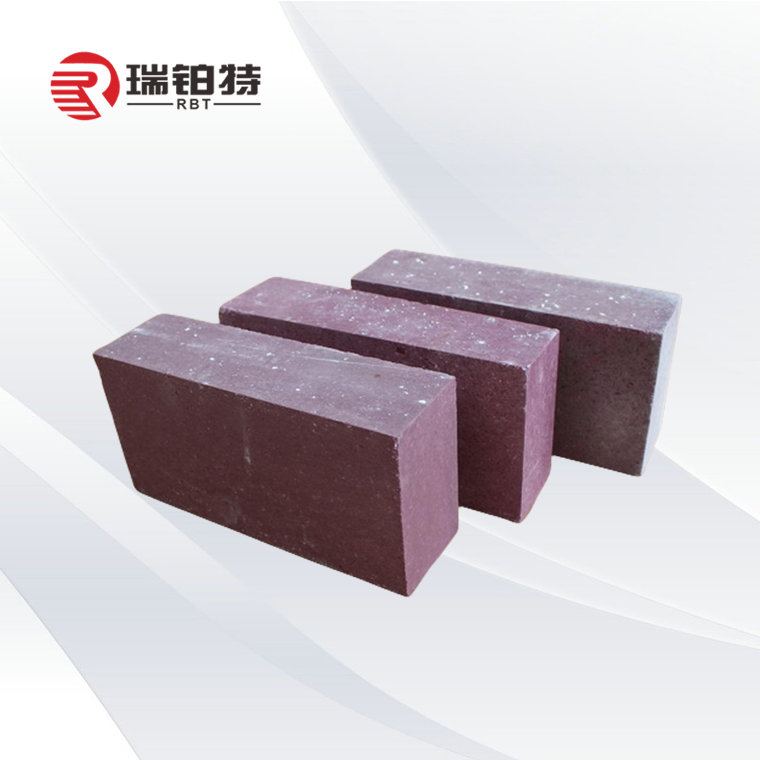

Chrome Corundum Bricks

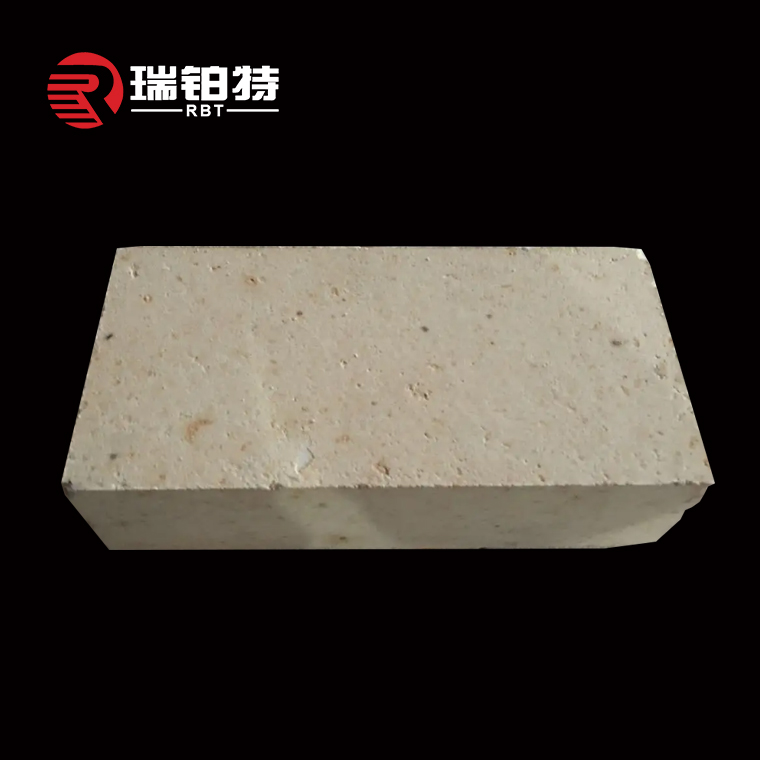

Zirconium Corundum Bricks

Chrome Zirconium Corundum Bricks

Product Index

|

INDEX

|

High Purity Corundum Brick

|

Sintered Corundum Brick

|

||

|

Bulk Density(g/cm3)

|

≤3.2

|

3.1

|

3.1

|

3

|

|

Cold Crushing Strength(MPa)

|

≥100

|

≥100

|

≥100

|

≥100

|

|

Permanent Linear Change@1600°×3h(%)

|

±0.2

|

±0.2

|

±0.3

|

±0.3

|

|

Refractoriness Under Load@0.2MPa(℃)

|

≥1700

|

≥1700

|

≥1700

|

≥1700

|

|

Al2O3(%)

|

≥99

|

≥95

|

≥92

|

≥90

|

|

Fe2O3(%)

|

≤0.15

|

≤0.4

|

≤0.5

|

≤0.5

|

|

SiO2(%)

|

≤0.3

|

≤4

|

≤7

|

≤9

|

|

INDEX

|

Chrome Corundum Brick

|

||

|

Bulk Density(g/cm3)

|

≥3.7

|

≥3.5

|

≥3.2

|

|

Apparent Porosity(%)

|

≤18

|

≤18

|

≤18

|

|

Cold Crushing Strength(MPa)

|

≥130

|

≥130

|

≥100

|

|

Refractoriness Under Load(0.1Mpa,0.6%) (℃)

|

≥1700

|

≥1700

|

≥1700

|

|

Al2O3(%)

|

≤68

|

≤80

|

-

|

|

Fe2O3(%)

|

≤0.2

|

≤0.3

|

≤0.5

|

|

Cr2O3(%)

|

≥30

|

≥12

|

≥8

|

|

INDEX

|

Sintered AZS-30

|

|

Bulk Density(g/cm3)

|

≥3.2

|

|

Apparent Porosity(%)

|

≤20

|

|

Cold Compression Strength(MPa)

|

≥100

|

|

Refractoriness Under Load(0.2Mpa,0.6%) (℃)

|

≥1650

|

|

Al2O3(%)

|

≥49

|

|

Fe2O3(%)

|

≤1.0

|

|

SiO2(%)

|

≤18

|

|

ZrO2(%)

|

≥30

|

Application

|

Products

|

Corundum Bricks

|

Chrome Corundum Bricks

|

Zirconium Corundum Bricks

|

|

Features

|

Corrosion resistance, abrasion resistance and high temperature strength, refractoriness under load, creep and other thermodynamic properties.

|

Excellent thermal vibration stability and high temperature creep performance, and excellent corrosion resistance.

|

High mechanical strength, good thermal stability, small high-temperature creep, stable chemical properties, and good acid and alkali corrosion resistance.

|

|

Application

|

Widely used in petrochemical, chemical industry, metallurgy industry, transformation of cracking furnace, gasifier, gasification reaction furnace, carbon black, pulp waste liquid gasification furnace and other industrial furnace.

|

It can be used as glass kiln lining, brushed glass flow hole cover brick and used in molten iron pretreatment device, garbage incinerator, coal water slurry pressurized gasification furnace backing, etc.

|

Used in key parts of glass kilns, fiberglass furnaces, waste incinerators, electric furnaces and other kilns.

|

Metallurgical Industry

Glass Kiln

Package&Warehouse

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

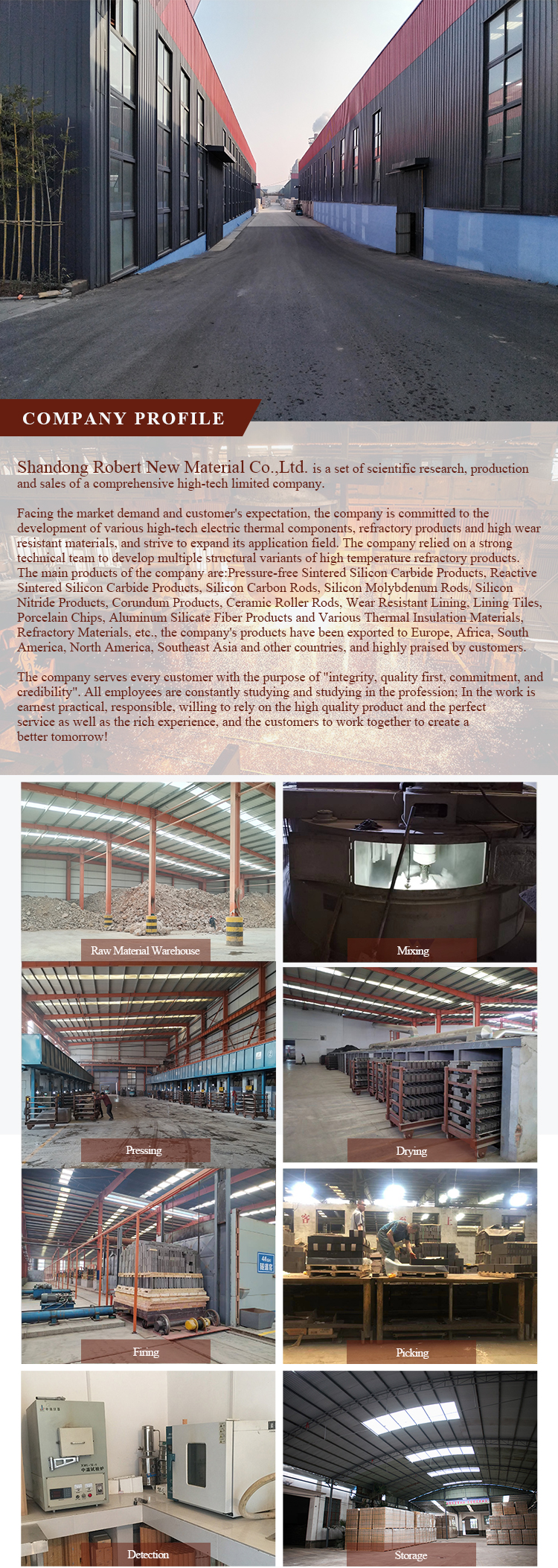

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.