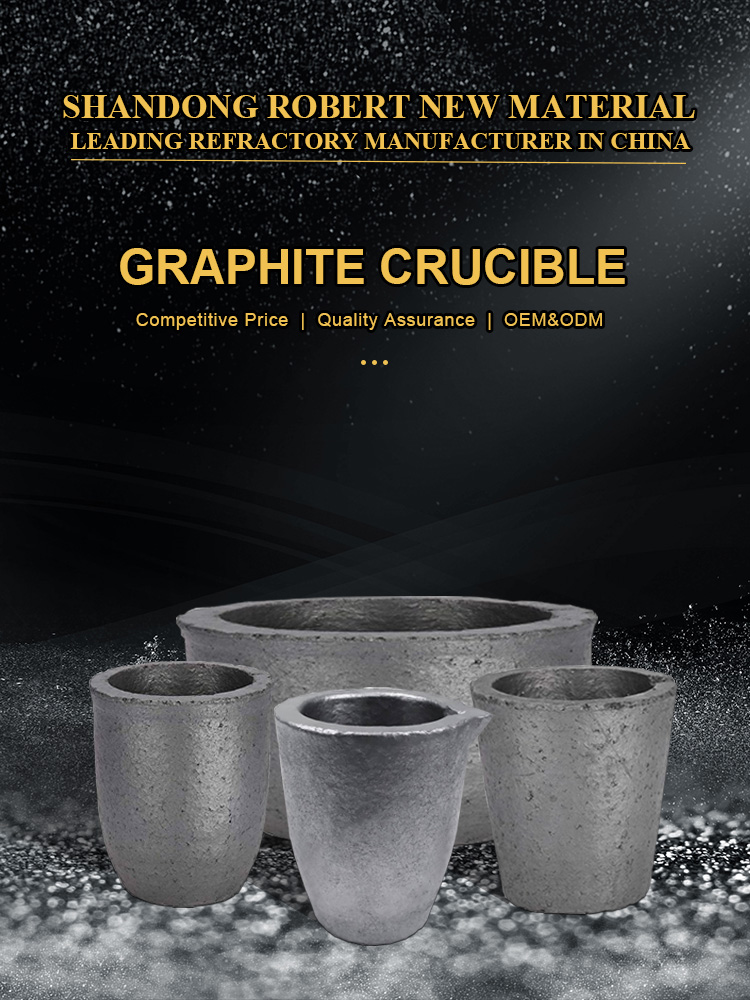

Graphite Crucible

Product Information

|

Product Name

|

Graphite Crucible

|

|

Description

|

Graphite crucible, also known as molten copper ladle, molten copper, etc., refers to a type of crucible made of graphite, clay, silica and wax stone as raw materials.

|

|

Classification

|

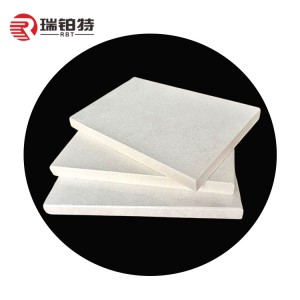

Silicon carbide/Clay bonded/Pure

|

|

Main Ingreadient

|

Graphite, silicon carbide, silica, refractory clay, pitch and tar

|

|

Size

|

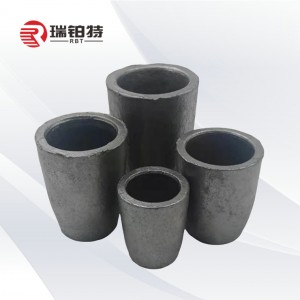

Regular size, special size and OEM service also provide!

|

|

Shape

|

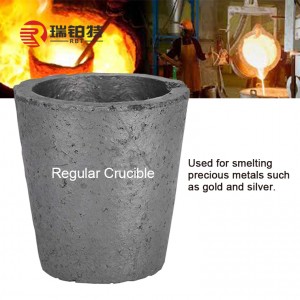

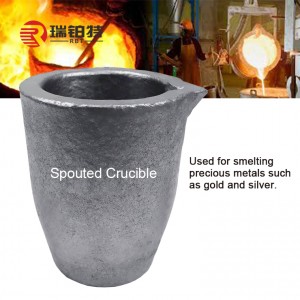

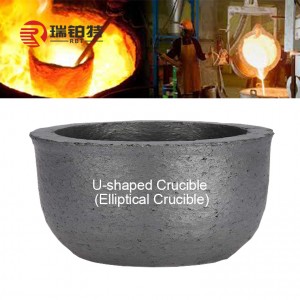

Regular crucible, spouted crucible, u-shaped crucible (elliptical crucible), and OEM service also provide!

|

|

Features

|

High temperature resistance; Strong thermal conductivity; Good corrosion resistance; Long service life

|

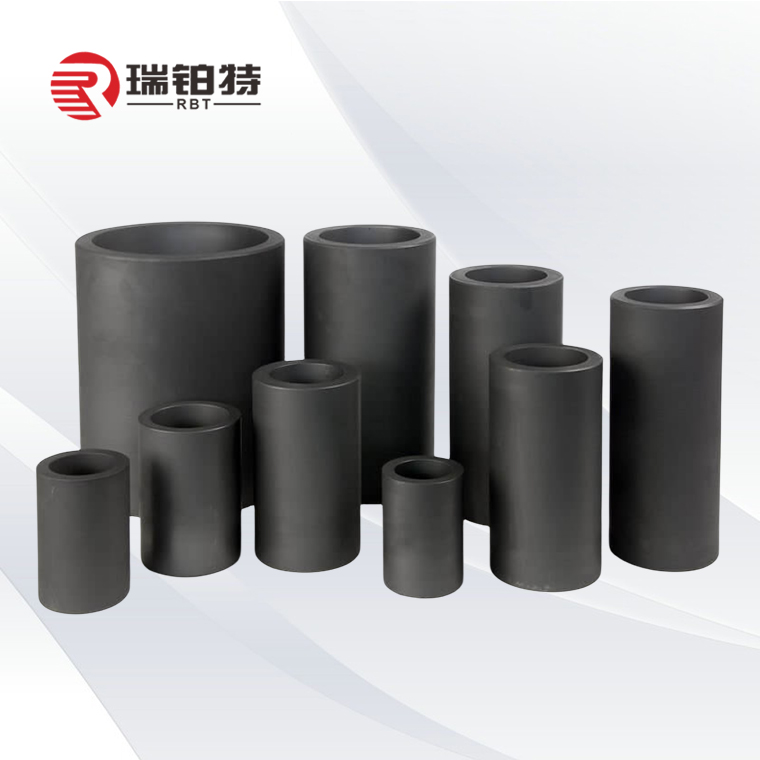

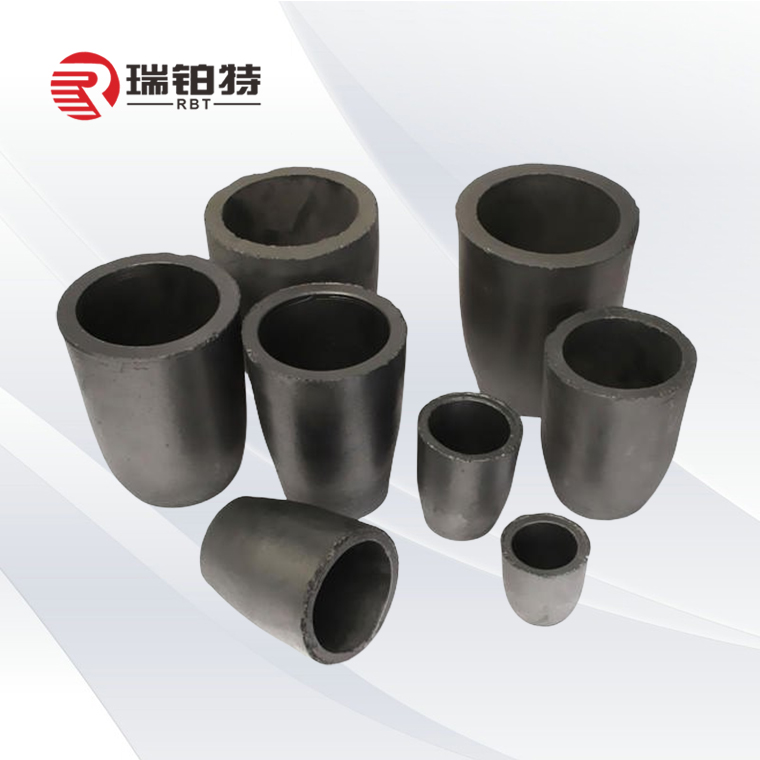

Details Images

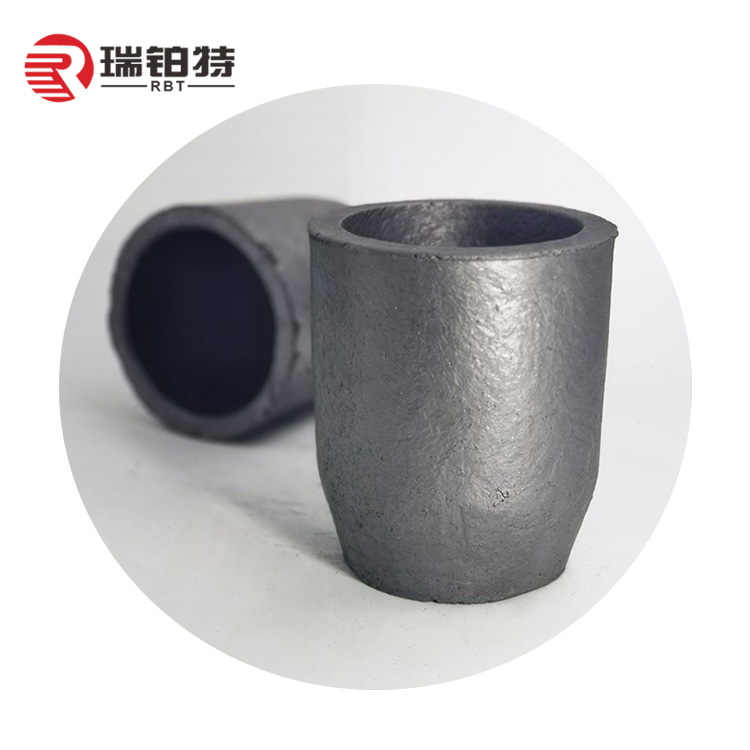

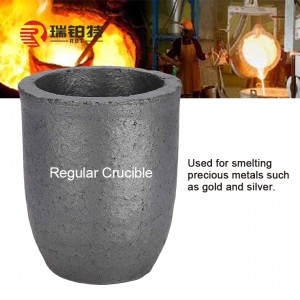

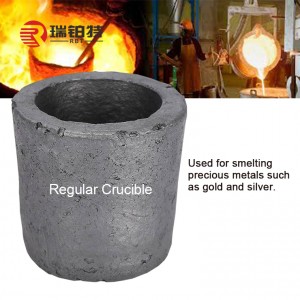

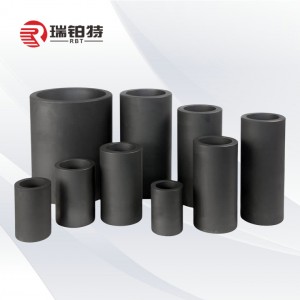

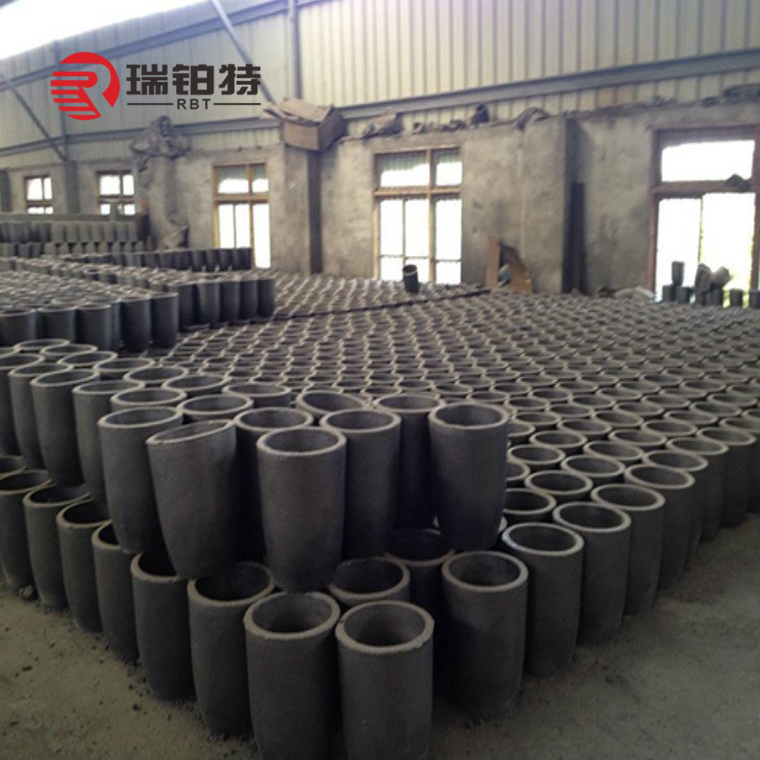

Regular Crucible

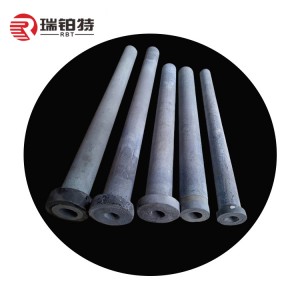

Spouted Crucible

Spouted Crucible

Crucible Combination

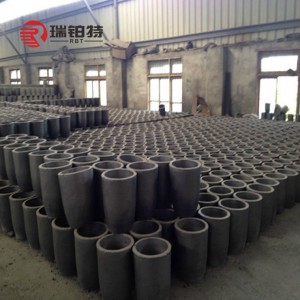

Crucible Combination

U-shaped Crucible (Elliptical Crucible)

Crucible Combination

Crucible Combination

Product Index

|

Performance Index/Unit

|

Index Value

|

Index Value

|

Index Value

|

|

Bulk Density g/cm3

|

1.82

|

1.85

|

1.90

|

|

Resistivity μΩm

|

11~13

|

11~13

|

8~9

|

|

Thermal Conductivity (100℃)W/m.k

|

110~120

|

100~120

|

130~140

|

|

Thermal Expansion Coefficient

(Room Temperature-600℃)10-6/℃

|

5.8

|

5.9

|

4.8

|

|

Shore Hardness HSD

|

65

|

68

|

53

|

|

Flexural Strength Mpa

|

51

|

62

|

55

|

|

Compressive Strength Mpa

|

115

|

135

|

95

|

|

Elastic Modulus Gpa

|

12

|

12

|

12

|

|

Porosity %

|

12

|

12

|

11

|

|

Ash PPM

|

500

|

500

|

500

|

|

Purified Ash PPM

|

50

|

50

|

50

|

|

Graininess μm

|

8~10

|

7

|

8~10

|

Application

1. In the process of high temperature use, the coefficient of thermal expansion is small, and it has certain strain resistance torapid cooling and rapid heating. It has strong corrosion resistance to acidic and alkaline solutions, has excellent chemical stability, and does not participate in any chemical reactions during the smelting process.

2. The inner wall of the graphite crucible is smooth, and the melted metal liquid is not easy to leak and adhere to the inner wall of the crucible, so that the metal liquid has good fluidity and castability, and is suitable for various mold casting.

3. Because graphite crucible has the above excellent characteristics, it is mainly used to smelt non-ferrous metals such as copper, brass, gold, silver, zinc and lead and their alloys.

Package&Warehouse

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.