Fire Clay Refractory Bricks

Product Information

|

Product Name

|

Fire clay bricks

|

|

Alumina Contents

|

35% to 45%

|

|

Material

|

Fire clay material

|

|

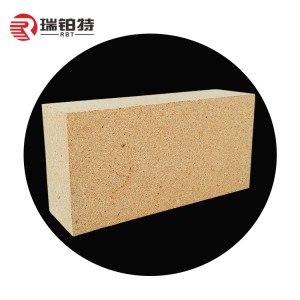

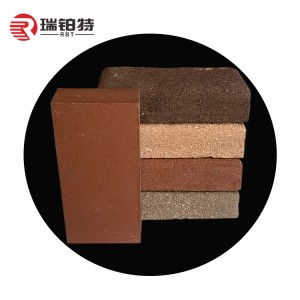

Color

|

Generally dark yellow, the higher the aluminum content, the lighter the color

|

|

Model Number

|

SK32, SK33, SK34, N-1, low porosity series,

special series (special for hot blast stove, special for coke oven, etc.)

|

|

Size

|

Standard size: 230 x 114 x 65 mm, special size and OEM service also provide!

|

|

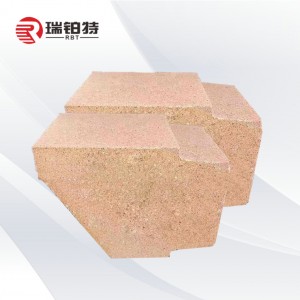

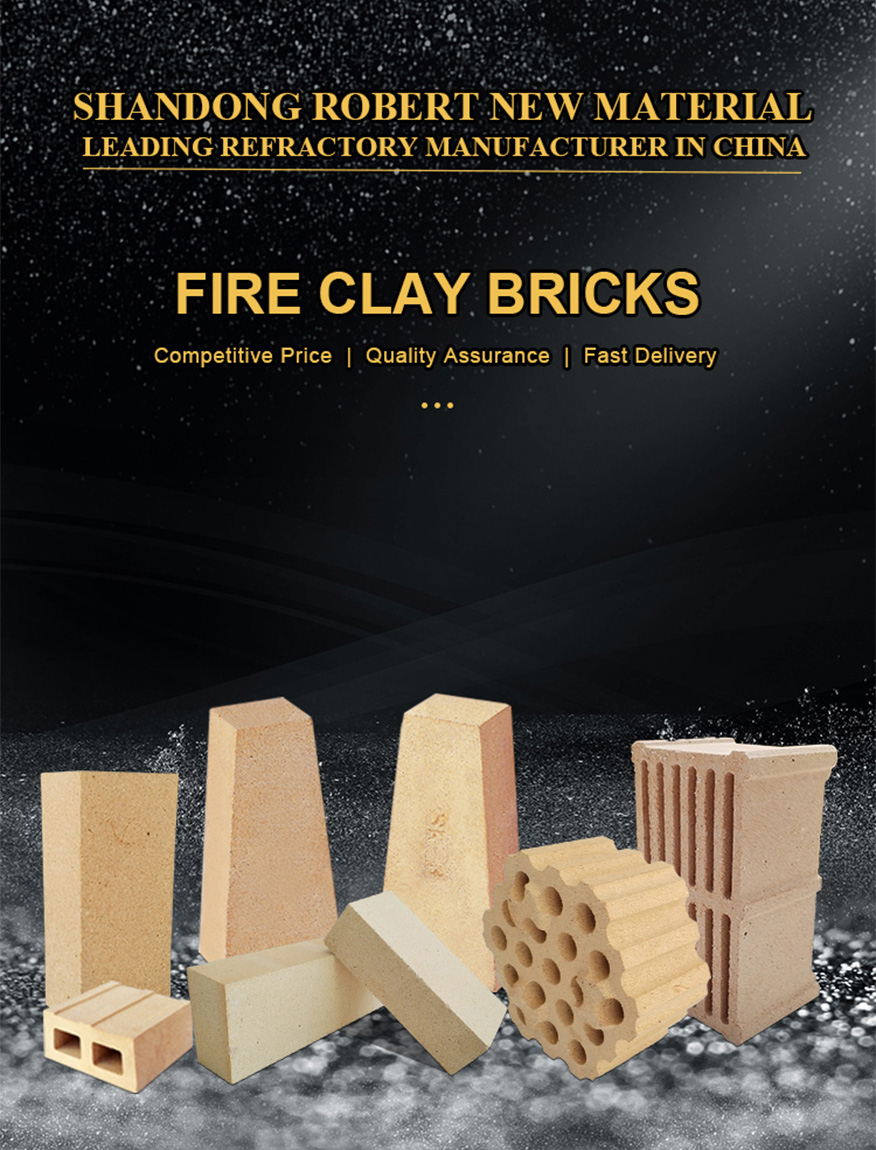

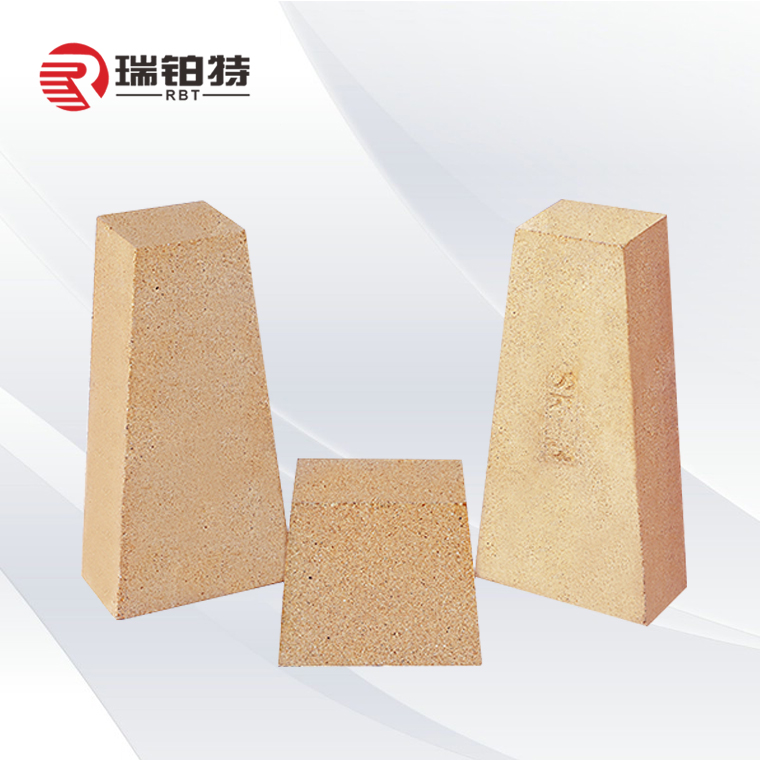

Shape

|

Straight brick, special-shaped brick, checher brick, trapezoidal brick, bricks with taper,

arch brick, skew brick, ect.

|

|

Features

|

1.Excellent resistance in slag abrasion;

2.Lower impurity content;

3.Good cold rush strength;

4.Lower thermal line expansion in high temp;

5.Good thermal shock resistance performance;

6.Good performance in high temp refractoriness under load.

|

description

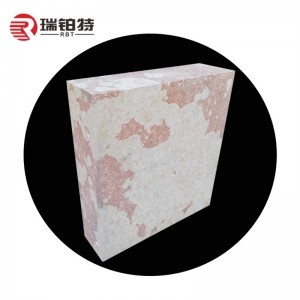

Fireclay bricks belong to one of the main varieties of aluminum silicate products. It is a refractory product made of clay clinker as aggregate and refractory soft clay as binder with Al2O3 content in 35%~45%.

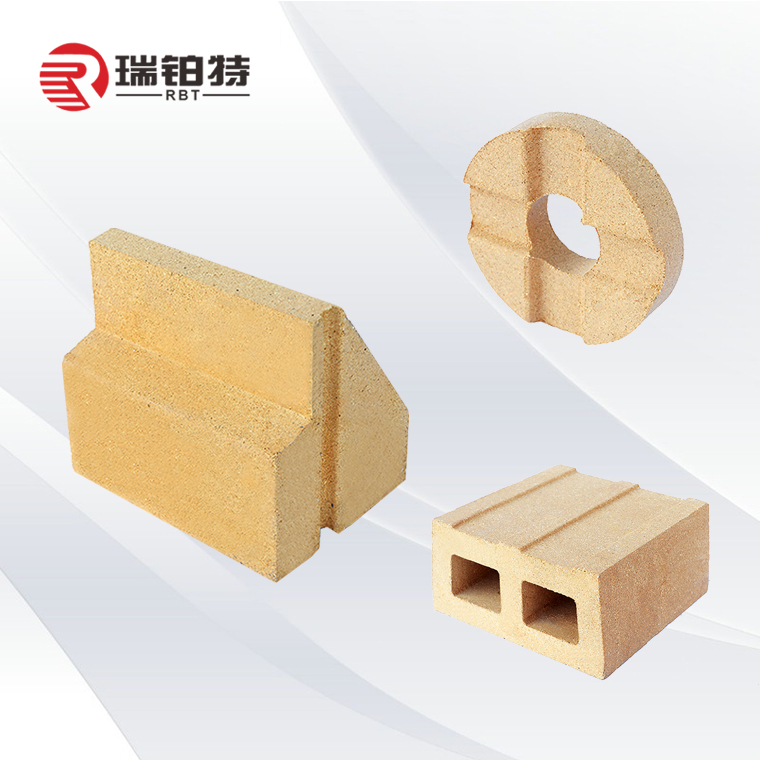

Details Images

Fire Clay Bricks

Clay Checker Bricks (For Coke Oven)

Clay Wedge Bricks

Clay Shaped Bricks

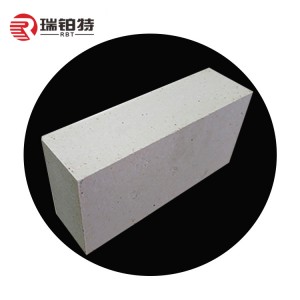

Low Porosity Clay Bricks

Clay Checker Bricks (For Hot Stoves)

Clay Wedge Bricks

Octagonal Bricks

Product Index

| INDEX PRODUCT | SK-32 | SK-33 | SK-34 |

| Refractoriness(℃) ≥ | 1710 | 1730 | 1750 |

| Bulk Density(g/cm3) ≥ | 2.00 | 2.10 | 2.20 |

| Apparent Porosity(%) ≤ | 26 | 24 | 22 |

| Cold Crushing Strength(MPa) ≥ | 20 | 25 | 30 |

| @1350°×2h Permanent Linear Chang(%) | ±0.5 | ±0.4 | ±0.3 |

| Refractoriness Under Load(℃) ≥ | 1250 | 1300 | 1350 |

| Al2O3(%) ≥ | 32 | 35 | 40 |

| Fe2O3(%) ≤ | 2.5 | 2.5 | 2.0 |

|

Low Porosity Clay Bricks Model

|

DN-12

|

DN-15

|

DN-17

|

|

Refractoriness(℃) ≥

|

1750

|

1750

|

1750

|

|

Bulk Density(g/cm3) ≥

|

2.35

|

2.3

|

2.25

|

|

Apparent Porosity(%) ≤

|

13

|

15

|

17

|

|

Cold Crushing Strength(MPa) ≥

|

45

|

42

|

35

|

|

Permanent Linear Change@1350°×2h(%)

|

±0.2

|

±0.25

|

±0.3

|

|

Refractoriness Under Load@0.2MPa(℃) ≥

|

1420

|

1380

|

1320

|

|

Al2O3(%) ≥

|

45

|

45

|

42

|

|

Fe2O3(%) ≤

|

1.5

|

1.8

|

2.0

|

Application

Clay bricks are widely used in blast furnaces, hot blast stoves, glass kilns, soaking furnaces, annealing furnaces, boilers, cast steel systems and other thermal equipment, and are one of the most consumed refractory products.

Reheating Furnace, Blast Furnace

Hot Blast Stove

Roller Kiln

Tunnel Kiln

Coke Oven

Rotary Kiln

Package&Warehouse