Magnesite Refractory Bricks Series

|

Product Name

|

Magnesite bricks/Magnesium bricks/Magnesia bricks

|

|

Mgo Contents

|

88% to 97.8%

|

|

Material

|

Mgo

|

|

Model Number

|

MG-91/MG-92/MG-95A/MG-95B/MG-97A/MG-97B/MG-98

|

|

Size

|

Standard size: 230 x 114 x 65 mm ,Special size and OEM Service also provide!

|

|

Shape

|

Straight bricks,Special-shaped bricks

|

|

Features

|

1.High refractoriness;

2.High strength at high temperature;

3.Good stable volume at high temperature;

4.Good resistance to alkaline slag.

|

description

Magnesite bricks are made of sintered magnesia, high purity magnesia and fused magnesia as raw materials, and magnesite is the main crystalline phase in the product.

Details Images

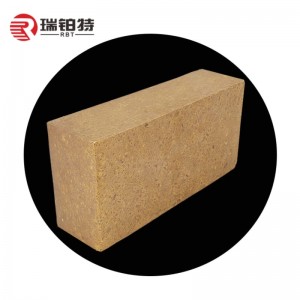

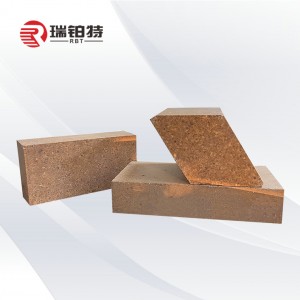

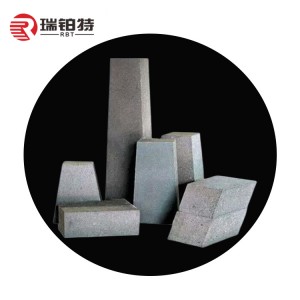

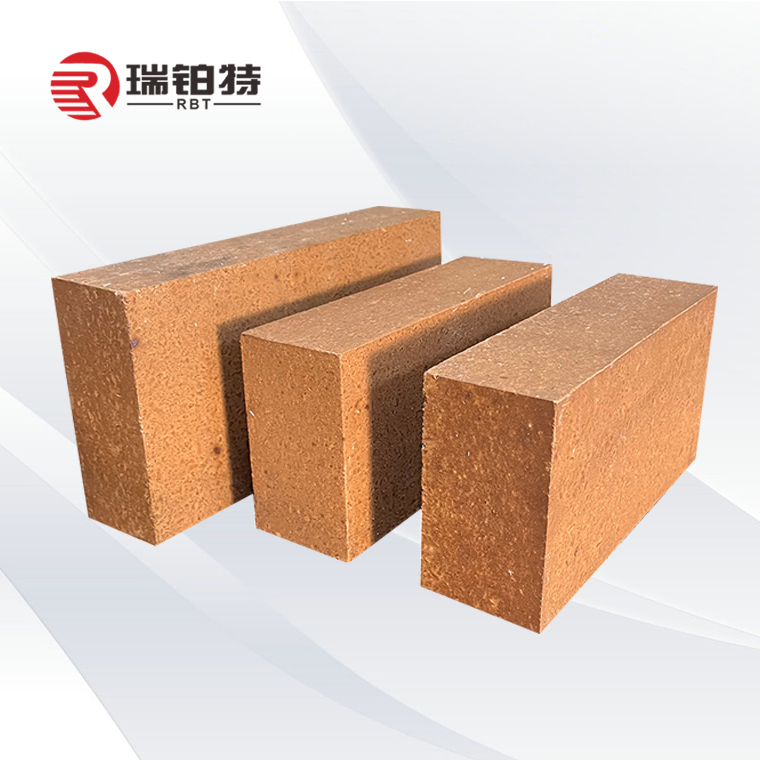

Standard Bricks

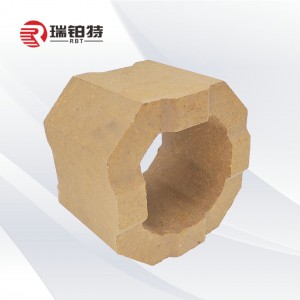

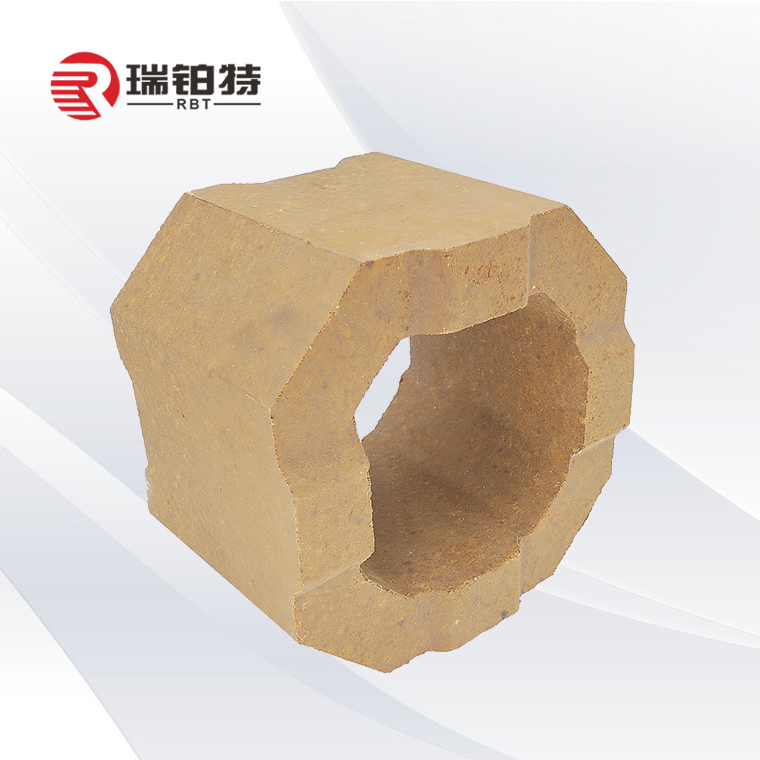

Octagonal Bricks

Standard Bricks

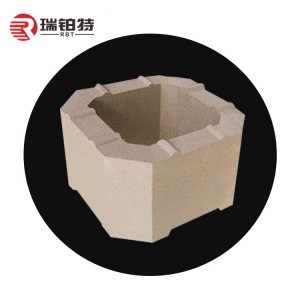

Shaped Bricks

Product Index

|

INDEX

|

MG-92

|

MG-95A

|

MG-95B

|

MG-97A

|

MG-97B

|

MG-98

|

|

Bulk Density(g/cm3) ≥

|

2.90

|

2.95

|

2.95

|

3.00

|

3.00

|

3.00

|

|

Apparent Porosity(%) ≤

|

18

|

17

|

18

|

17

|

17

|

17

|

|

Cold Crushing Strength(MPa) ≥

|

60

|

60

|

60

|

60

|

60

|

60

|

|

Refractoriness Under Load @0.2MPa(℃) ≥

|

1580

|

1650

|

1620

|

1700

|

1680

|

1700

|

|

MgO(%) ≥

|

92

|

95

|

94.5

|

97

|

96.5

|

97.5

|

|

SiO2(%) ≤

|

4.0

|

2.0

|

2.5

|

1.2

|

1.5

|

0.6

|

|

CaO(%) ≤

|

2.5

|

2.0

|

2.0

|

1.5

|

2.0

|

1.0

|

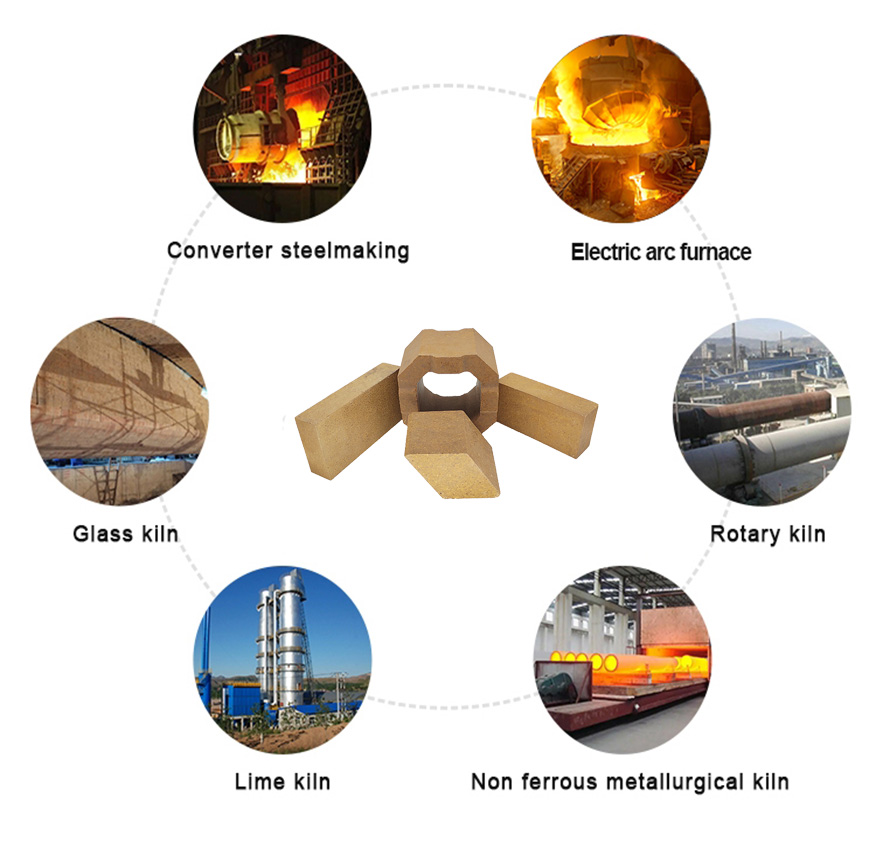

Application

Mainly used in the permanent lining of steel furnace, lime kiln, glass kiln regenerator, ferroalloy furnace, mixed iron furnace, non-ferrous metal furnace and the lining of other steel, non-ferrous metallurgy furnace and building materials industry kiln.

Package&Warehouse