Refractory Castable

Product Description

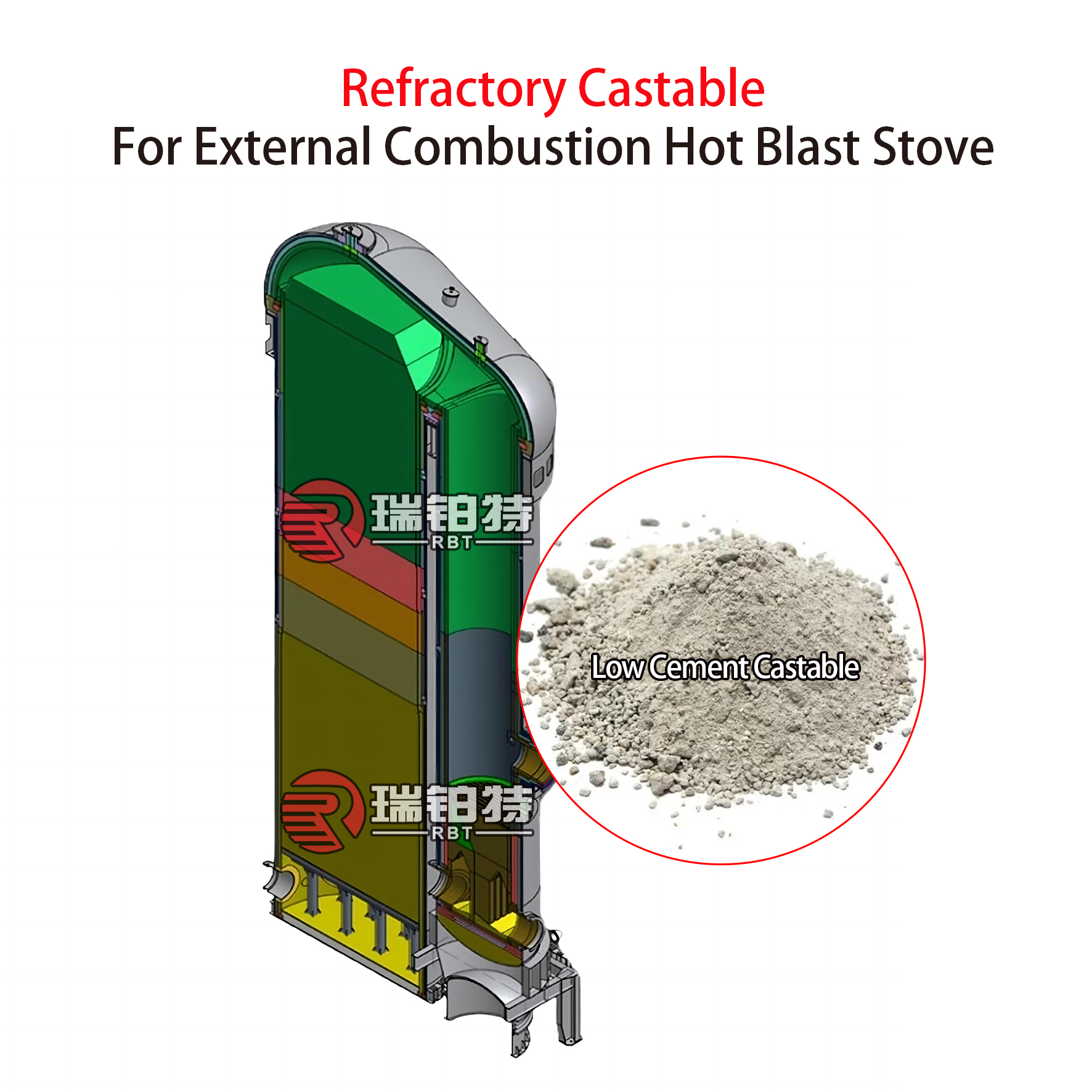

Refractory castables are a mixture of refractory aggregates, powders and binders. After adding water or other liquids, they are suitable for construction by pouring and vibration methods. They can also be prefabricated into prefabricated parts with specified shapes and sizes for the construction of industrial furnace linings. In order to improve the physical and chemical properties and construction performance of refractory castables, appropriate amounts of admixtures are often added, such as plasticizers, dispersants, accelerators, retarders, expansion agents, debonding-gelling agents, etc. In addition, for refractory castables used in areas with large mechanical forces or strong thermal shock, if an appropriate amount of stainless steel fiber is added, the toughness of the material will be significantly increased. In the insulating refractory castable, if inorganic fibers are added, it can not only enhance the toughness, but also help improve its thermal insulation properties. Since the basic material composition of refractory castables (such as aggregates and powders, admixtures, binders and admixtures), coagulation and hardening process, construction methods, etc., are similar to concrete in civil engineering, it was once called refractory concrete.

Product Index

|

Product Name

|

Lightweight Castable

|

||||||

|

Working Limit Temperature

|

1100

|

1200

|

1400

|

1500

|

1600

|

||

|

110℃ Bulk Density(g/cm3) ≥

|

1.15

|

1.25

|

1.35

|

1.40

|

1.50

|

||

|

Modulus of Rupture(MPa) ≥

|

110℃×24h

|

2.5

|

3

|

3.3

|

3.5

|

3.0

|

|

|

1100℃×3h

|

2

|

2

|

2.5

|

3.5

|

3.0

|

||

|

1400℃×3h

|

―

|

―

|

3

|

10.8

|

8.1

|

||

|

Cold Crushing Strength(MPa) ≥

|

110℃×24h

|

8

|

8

|

11

|

12

|

10

|

|

|

1100℃×3h

|

4

|

4

|

5

|

11

|

10

|

||

|

1400℃×3h

|

―

|

―

|

15

|

22

|

14

|

||

|

Permanent Linear Change(%)

|

1100℃×3h

|

-0.65 1000℃×3h

|

-0.8

|

-0.25

|

-0.15

|

-0.1

|

|

|

1400℃×3h

|

―

|

―

|

-0.8

|

-0.55

|

-0.45

|

||

|

Thermal Conductivity(W/m.k)

|

350℃

|

0.18

|

0.20

|

0.30

|

0.48

|

0.52

|

|

|

700℃

|

0.25

|

0.25

|

0.45

|

0.61

|

0.64

|

||

|

Al2O3(%) ≥

|

33

|

35

|

45

|

55

|

65

|

||

|

Fe2O3(%) ≤

|

3.5

|

3.0

|

2.5

|

2.0

|

2.0

|

||

|

Product Name

|

Low Cement Castable

|

|||||

|

INDEX

|

RBTZJ-42

|

RBTZJ-60

|

RBTZJ-65

|

RBTZJS-65

|

RBTZJ-70

|

|

|

Working Limit Temperature

|

1300

|

1350

|

1400

|

1400

|

1450

|

|

|

Bulk Density(g/cm3) 110℃×24h≥

|

2.15

|

2.3

|

2.4

|

2.4

|

2.45

|

|

|

Cold Bending Strength

110℃×24h(MPa) ≥

|

4

|

5

|

6

|

6

|

7

|

|

|

Cold Crushing Strength(MPa) ≥

|

110℃×24h

|

25

|

30

|

35

|

35

|

40

|

|

CT℃×3h

|

50

1300℃×3h

|

55

1350℃×3h

|

60

1400℃×3h

|

40

1400℃×3h

|

70

1400℃×3h

|

|

|

Permanent Linear Change

@CT℃ × 3h(%)

|

-0.5~+0.5

1300℃

|

-0.5~+0.5

1350℃

|

0~+0.8

1400℃

|

0~+0.8

1400℃

|

0~+1.0

1400℃

|

|

|

Thermal Shock Resistance

(1000℃water) ≥

|

―

|

―

|

―

|

20

|

―

|

|

|

Al2O3(%) ≥

|

42

|

60

|

65

|

65

|

70

|

|

|

CaO(%) ≤

|

2-3

|

2-3

|

2-3

|

2-3

|

2-3

|

|

|

Fe2O3(%) ≤

|

2.0

|

1.5

|

1.5

|

1.5

|

1.5

|

|

|

Product Name

|

High Strength Castable

|

|||||

|

INDEX

|

HS-50

|

HS-60

|

HS-70

|

HS-80

|

HS-90

|

|

|

Working Limit Temperature(℃)

|

1400

|

1500

|

1600

|

1700

|

1800

|

|

|

110℃ Bulk Density(g/cm3) ≥

|

2.15

|

2.30

|

2.40

|

2.50

|

2.90

|

|

|

Modulus of Rupture

(MPa) ≥

|

110℃×24h

|

6

|

8

|

8

|

8.5

|

10

|

|

1100℃×3h

|

8

|

8.5

|

8.5

|

9

|

9.5

|

|

|

1400℃×3h

|

8.5 1300℃×3h

|

9

|

9.5

|

10

|

15

|

|

|

Cold Crushing Strength(MPa)≥

|

110℃×24h

|

35

|

40

|

40

|

45

|

60

|

|

1100℃×3h

|

40

|

50

|

45

|

50

|

70

|

|

|

1400℃×3h

|

45 1300℃×3h

|

55

|

50

|

55

|

100

|

|

|

Permanent Linear Change(%)

|

1100℃×3h

|

-0.2

|

-0.2

|

-0.25

|

-0.15

|

-0.1

|

|

1400℃×3h

|

-0.45 1300℃×3h

|

-0.4

|

-0.3

|

-0.3

|

-0.1

|

|

|

Al2O3(%) ≥

|

48

|

48

|

55

|

65

|

75

|

90

|

|

CaO(%) ≤

|

4.0

|

4.0

|

4.0

|

4.0

|

4.0

|

4.0

|

|

Fe2O3(%) ≤

|

3.5

|

3.5

|

3.0

|

2.5

|

2.0

|

2.0

|

Application

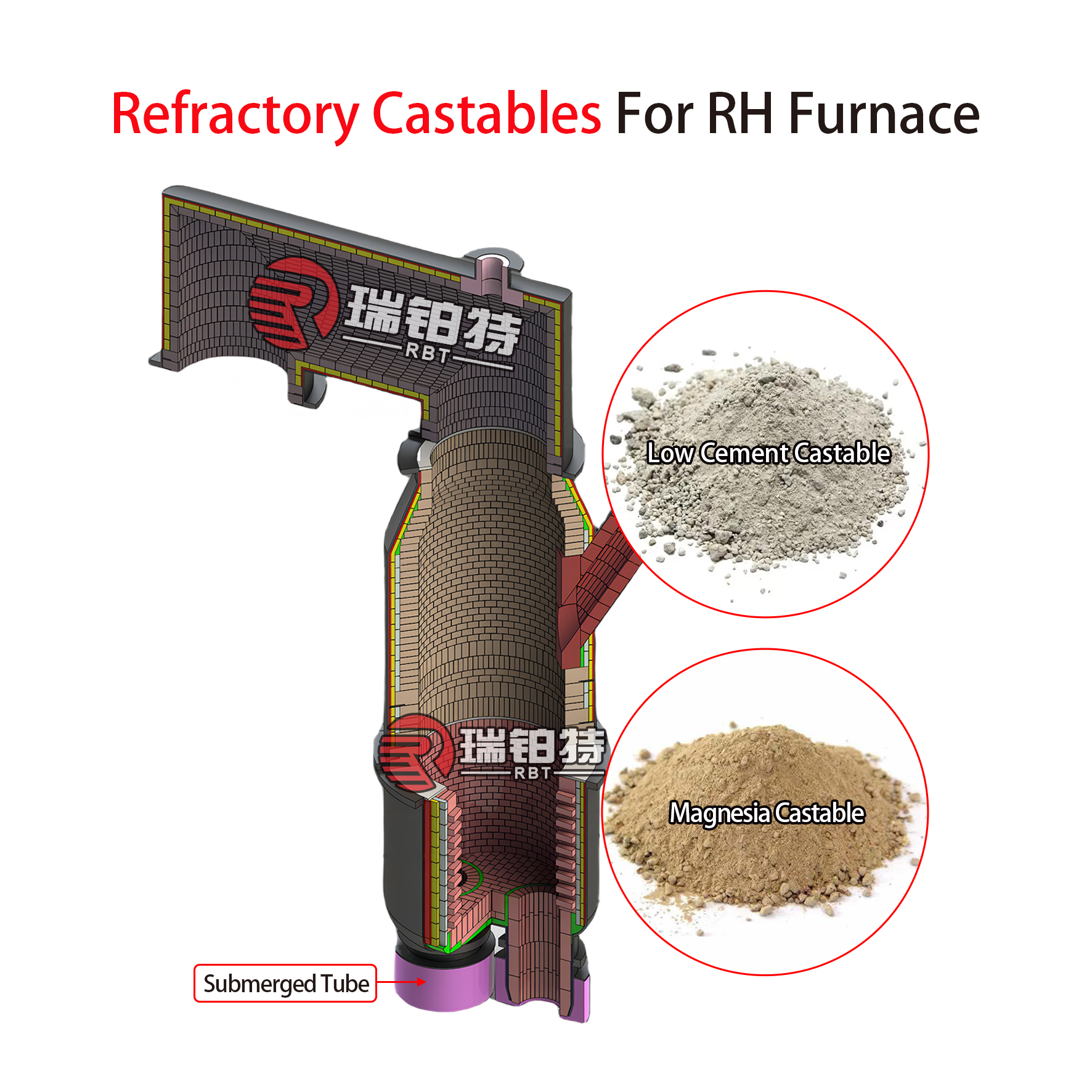

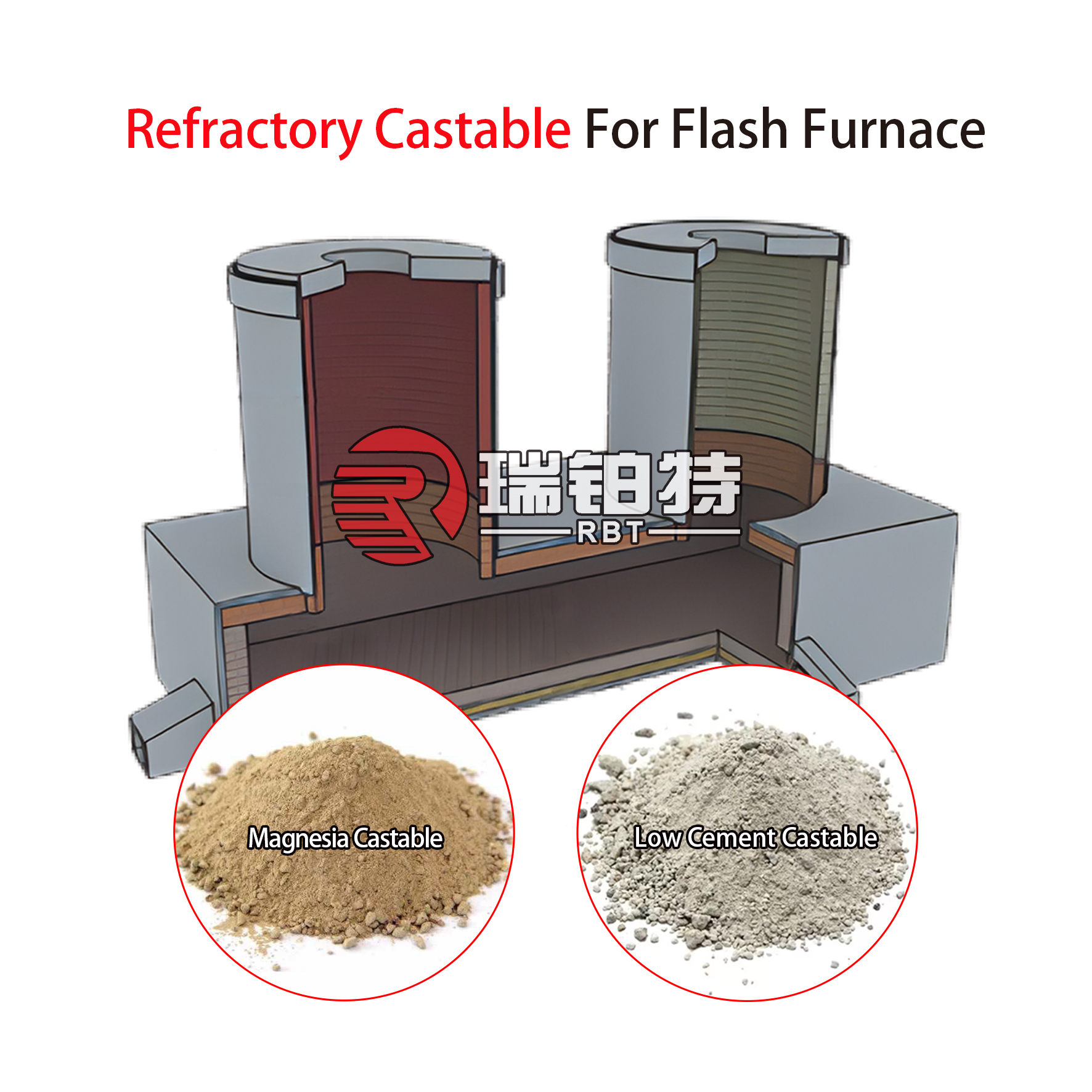

1. High-aluminum castable: High-aluminum castable is mainly composed of alumina (Al2O3) and has high refractoriness, slag resistance and thermal shock resistance. It is widely used in high-temperature furnaces and hearths in the steel, non-ferrous metals, chemical and other industries.

2. Steel fiber reinforced castable: Steel fiber reinforced castable is based on ordinary castables and steel fibers are added to enhance its thermal shock resistance, wear resistance and slag resistance. It is mainly used in furnaces, furnace bottoms and other parts in the steel, metallurgy, petrochemical and other industries.

3. Mullite castable: Mullite castable is mainly composed of mullite (MgO·SiO2) and has good wear resistance, refractoriness and slag resistance. It is commonly used in key parts such as steelmaking furnaces and converters in the steel, metallurgy and other industries.

4. Silicon carbide castable: Silicon carbide castable is mainly composed of silicon carbide (SiC) and has excellent wear resistance, slag resistance and thermal shock resistance. Widely used in high-temperature furnaces, furnace beds and other parts of non-ferrous metals, chemicals, ceramics and other industries.

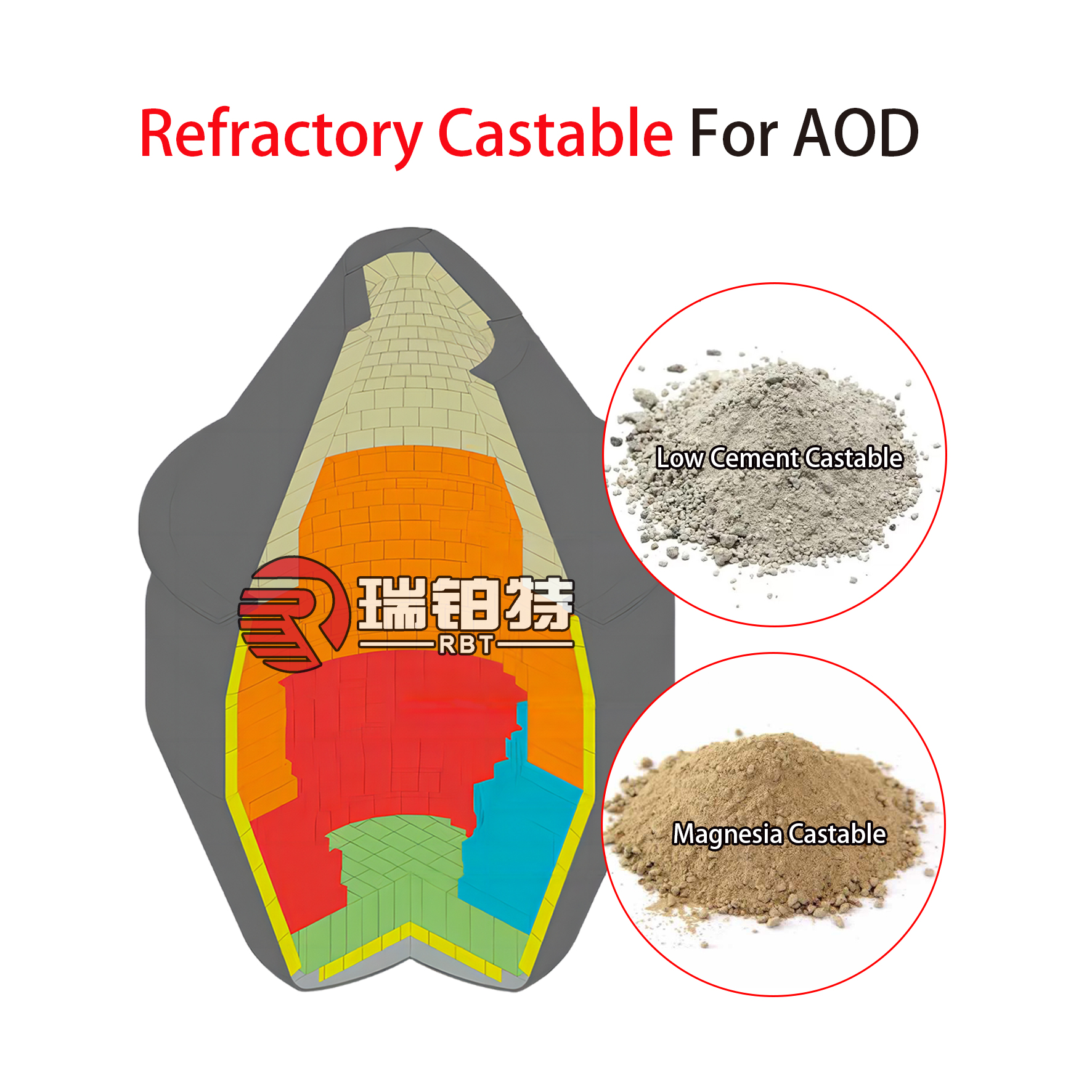

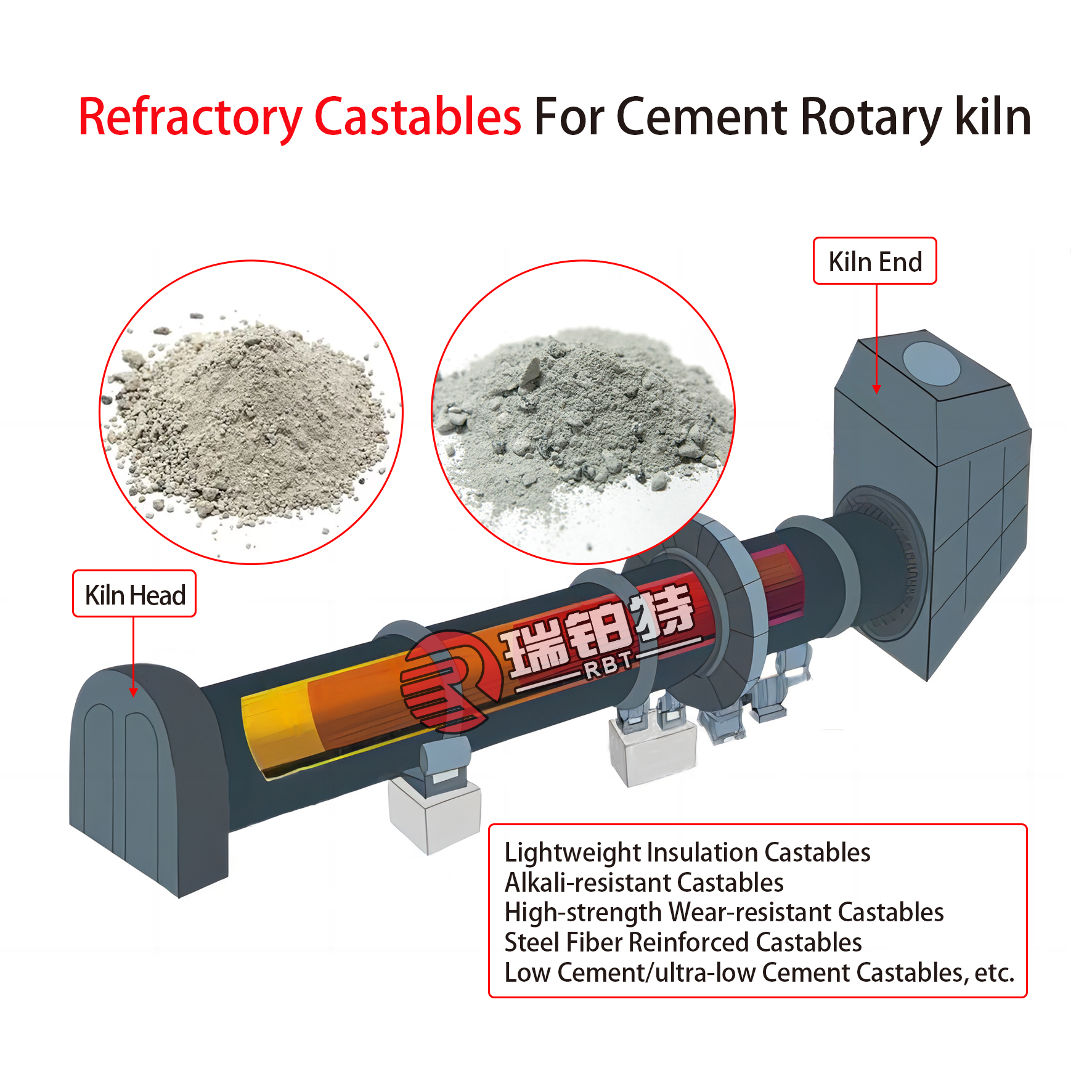

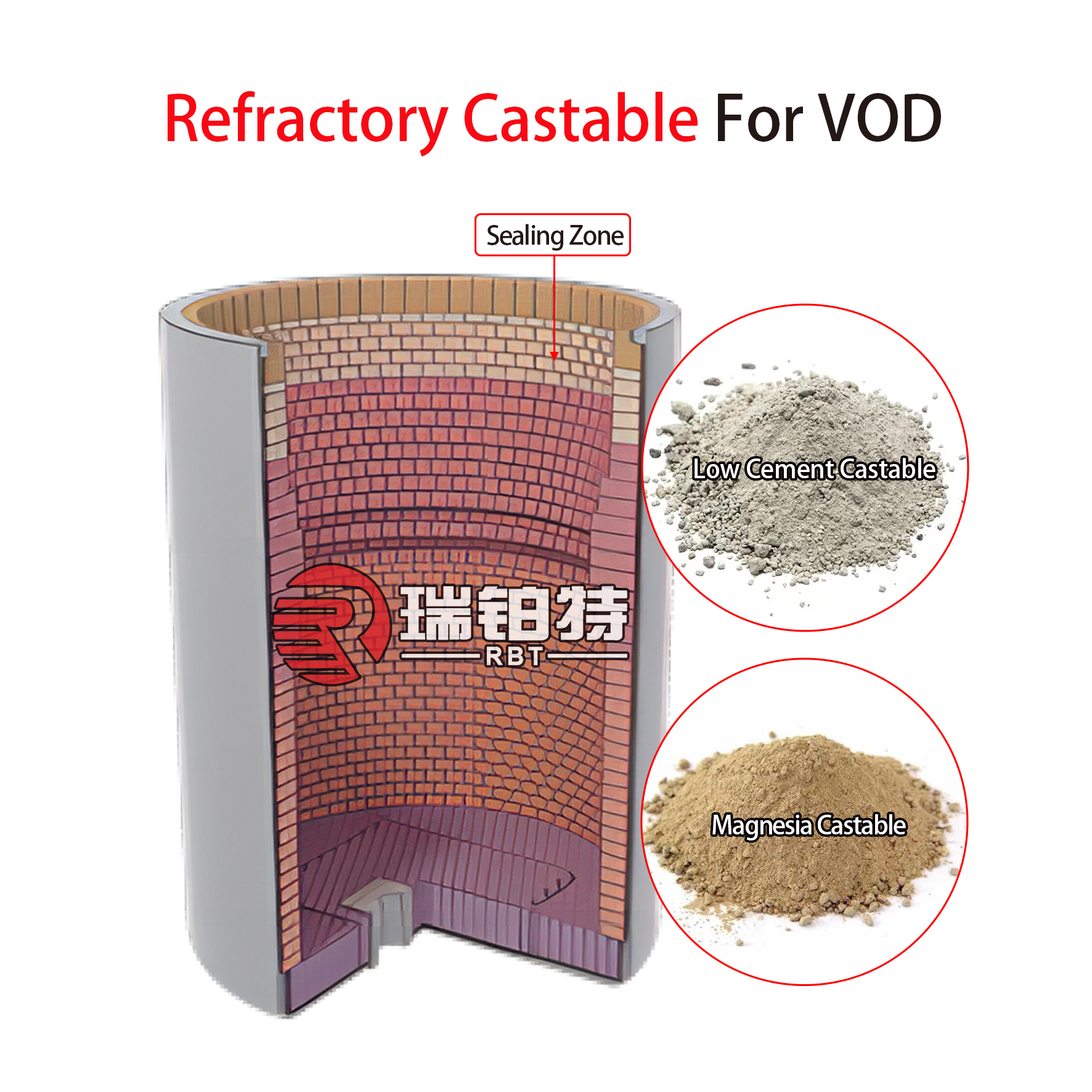

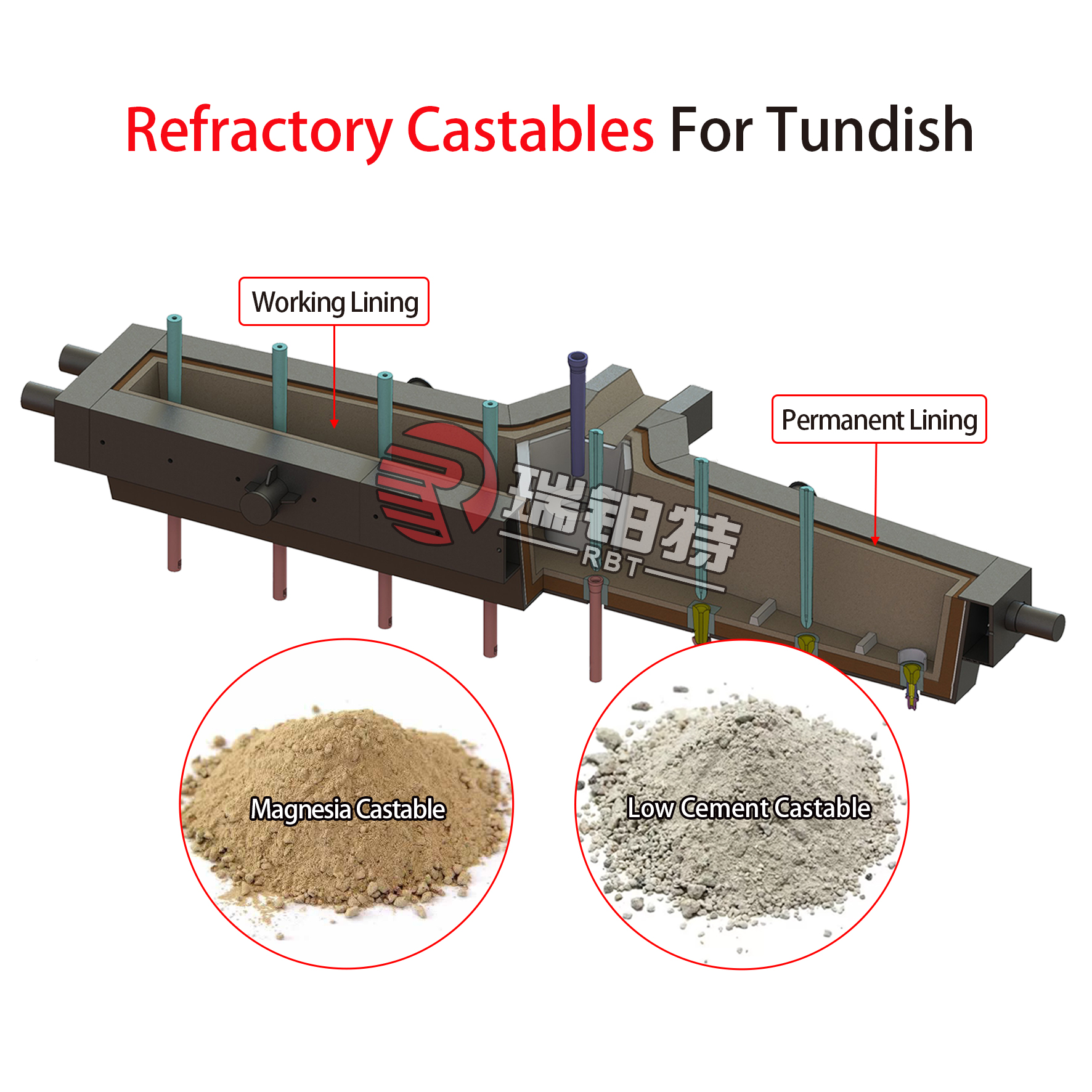

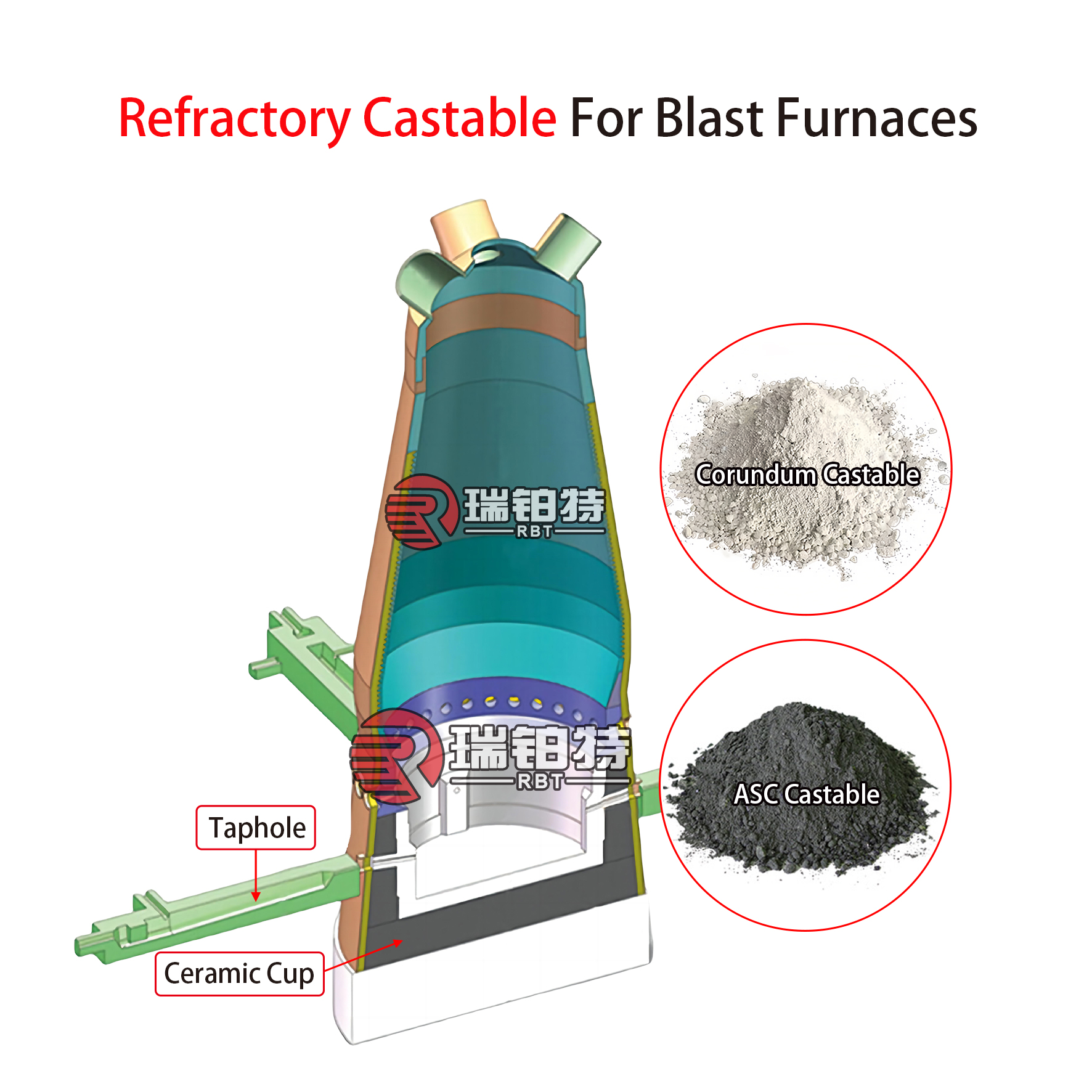

5. Low-cement castables: refers to castables with low cement content, which is generally about 5%, and some are even reduced to 1% to 2%. Low-cement castables use ultra-fine particles not exceeding 1μm, and their thermal shock resistance, slag resistance and erosion resistance are significantly improved. Low-cement castables are suitable for linings of various heat treatment furnaces, heating furnaces, vertical kilns, rotary kilns, electric furnace covers, blast furnace tapping holes, etc.; self-flowing low-cement castables are suitable for integral spray gun linings for spray metallurgy, high-temperature wear-resistant linings for petrochemical catalytic cracking reactors, and outer linings of heating furnace water cooling pipes.

6. Wear-resistant refractory castables: The main components of wear-resistant refractory castables include refractory aggregates, powders, additives and binders. Wear-resistant refractory castables are a type of amorphous refractory material widely used in metallurgy, petrochemicals, building materials, power and other industries. This material has the advantages of high temperature resistance, wear resistance, and erosion resistance. It is used to repair and protect the lining of high-temperature equipment such as furnaces and boilers to increase the service life of the equipment.

7. Ladle castable: Ladle castable is an amorphous refractory castable made of high-quality high-alumina bauxite clinker and silicon carbide as the main materials, with pure aluminate cement binder, dispersant, shrinkage-proof agent, coagulant, explosion-proof fiber and other additives. Because it has a good effect in the working layer of the ladle, it is also called aluminum silicon carbide castable.

8. Lightweight insulating refractory castable: Lightweight insulating refractory castable is a refractory castable with light weight, high strength and excellent thermal insulation performance. It is mainly composed of lightweight aggregates (such as perlite, vermiculite, etc.), high-temperature stable materials, binders and additives. It is widely used in various high-temperature industrial equipment, such as industrial furnaces, heat treatment furnaces, steel furnaces, glass melting furnaces, etc., to improve the energy utilization efficiency of equipment and reduce energy consumption.

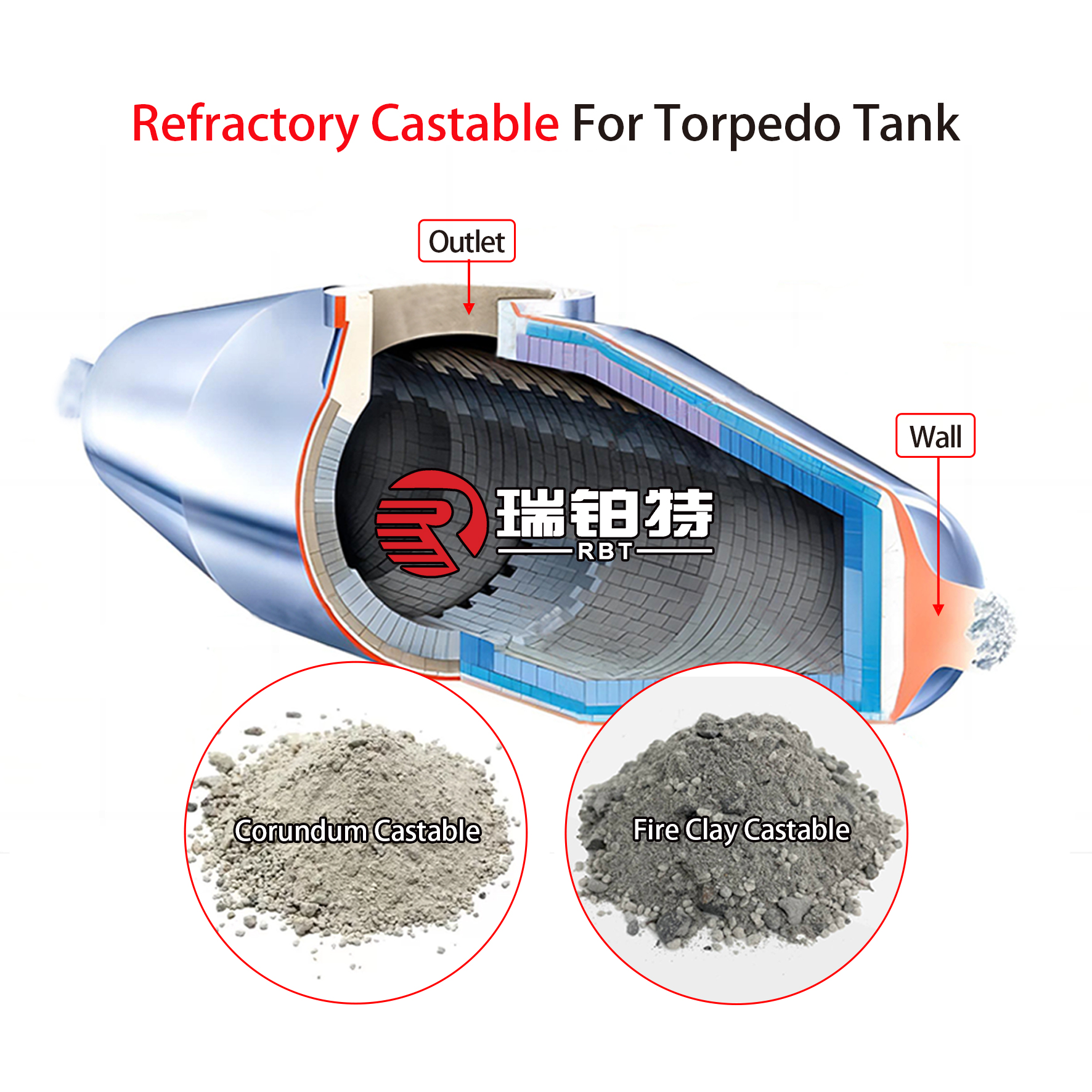

9. Corundum castable: With its excellent performance, corundum castable has become an ideal choice for key parts of thermal kilns. The characteristics of corundum castable are high strength, high load softening temperature and good slag resistance, etc. The general use temperature is 1500-1800℃.

10. Magnesium castable: Mainly used in high-temperature thermal equipment, it has excellent resistance to alkaline slag corrosion, low oxygen potential index and no pollution to molten steel. Therefore, it has a wide range of application prospects in the metallurgical industry, especially in the production of clean steel and the building materials industry.

11. Clay castable: The main components are clay clinker and combined clay, with good thermal stability and certain refractoriness, and the price is relatively low. It is often used in the lining of general industrial kilns, such as heating furnaces, annealing furnaces, boilers, etc. It can withstand a certain temperature of heat load and play a role in heat insulation and protection of the furnace body.

12. Dry castables: Dry castables are mainly composed of refractory aggregates, powders, binders and water. Common ingredients include clay clinker, tertiary alumina clinker, ultrafine powder, CA-50 cement, dispersants and siliceous or feldspar impermeable agents.

Dry castables can be divided into many types according to their uses and ingredients. For example, dry impermeable castables are mainly used in aluminum electrolytic cells, which can effectively prevent the penetration of electrolytes and extend the service life of the cells. In addition, dry refractory castables are suitable for hardware, smelting, chemical industry, non-ferrous metals and other industries, especially in the steel industry, such as rotary kiln front kiln mouth, disintegration furnace, kiln head cover and other parts.

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Our main products of refractory materials include: alkaline refractory materials; aluminum silicon refractory materials; unshaped refractory materials; insulation thermal refractory materials; special refractory materials; functional refractory materials for continuous casting systems.

Robert`s products are widely used in high-temperature kilns such as non-ferrous metals, steel, building materials and construction, chemical, electric power, waste incineration, and hazardous waste treatment. They are also used in steel and iron systems such as ladles, EAF, blast furnaces, converters, coke ovens, hot blast furnaces; non-ferrous metallurgical kilns such as reverberators, reduction furnaces, blast furnaces, and rotary kilns; building materials industrial kilns such as glass kilns, cement kilns, and ceramic kilns; other kilns such as boilers, waste incinerators, roasting furnace, which have achieved good results in using. Our products are exported to Southeast Asia, Central Asia, Middle East, Africa, Europe, Americas and other countries, and has established a good cooperation foundation with multiple well-known steel enterprises. All employees of Robert sincerely look forward to working with you for a win-win situation.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.