Mosi2 Heating Element

Product Information

|

Product Name

|

Silicon Molybdenum Rod/Mosi2 Heating Element

|

||

|

Description

|

Mosi2 heating element is a kind of resistance heating element basically made of high pure Molybdenum Disilicide. In oxidizing atmosphere, a layer of compact quartz protective film is formed on the surface of Mosi2 elementowing to the high temperature combustion, which prevent Mosi2 from continuously oxidizing. In oxidizing atmosphere, its Max temperafure can reach 1800'C, and its applicable temperature is 500- 1700'C. lt can be widely used in such applications as sintering and heat treatment of ceramics, magnet, glass, metallurgy, refractory, etc.

|

||

|

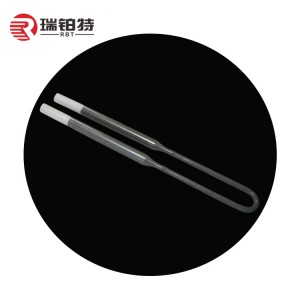

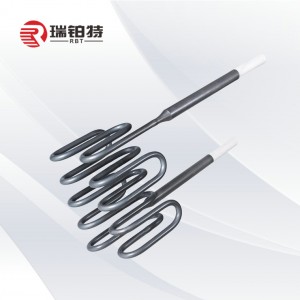

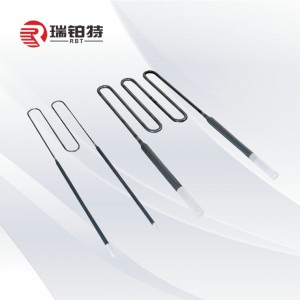

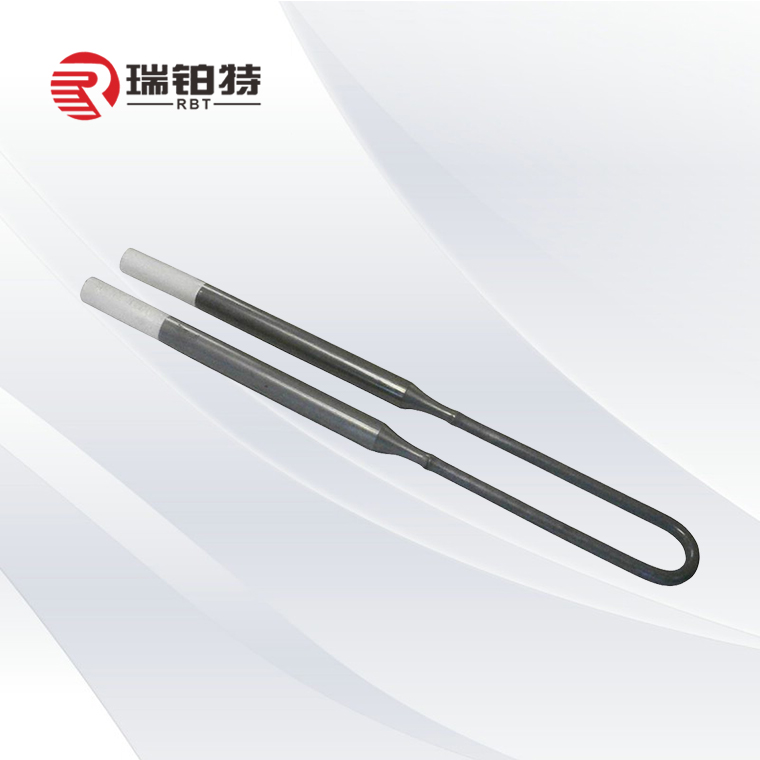

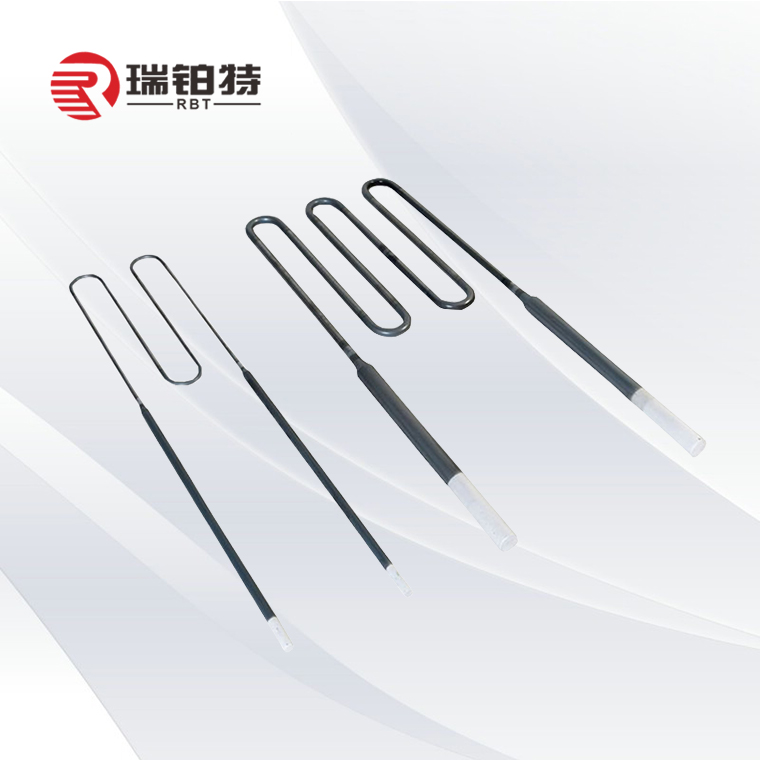

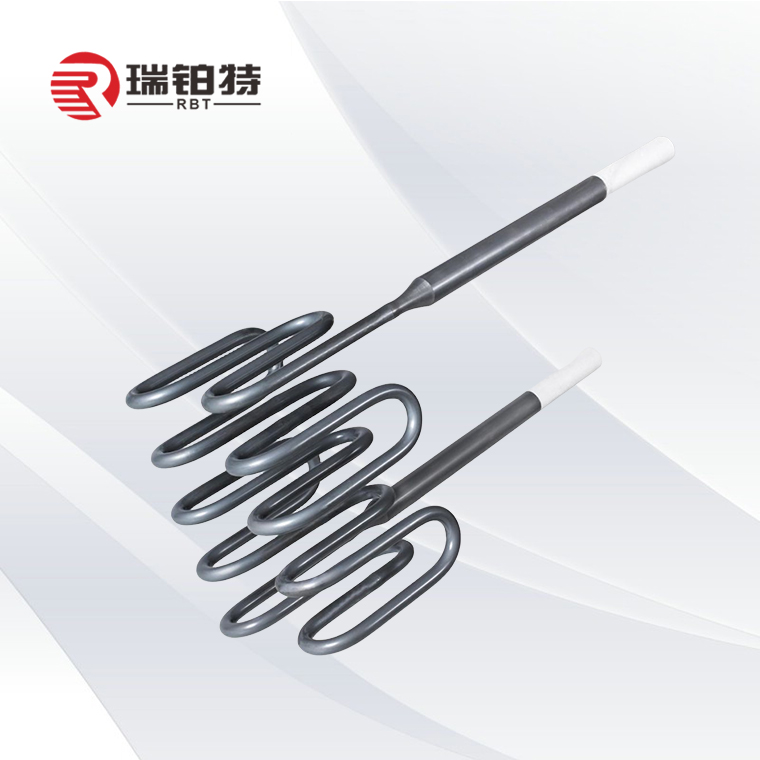

Shape

|

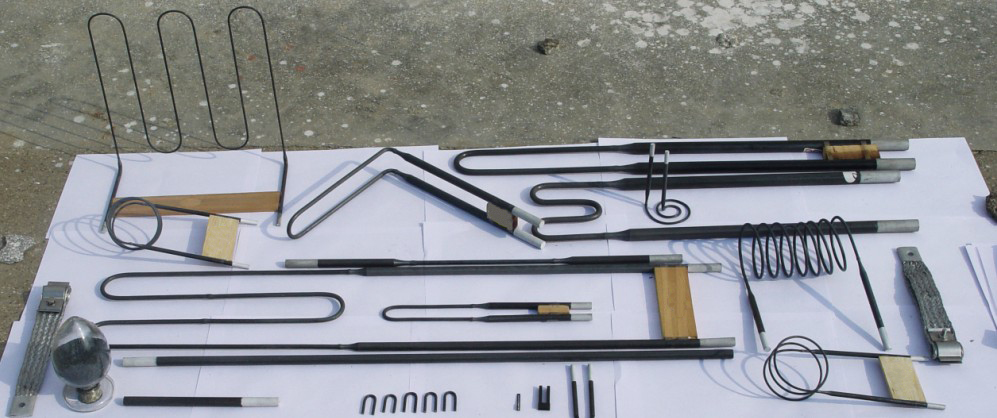

U-shaped; W-shaped; Customizable shape

|

||

|

Features

|

1. Good high temperature performance

2. Strong oxidation resistance

3. High mechanical strength

4. Good electrical properties

5. Strong corrosion resistance

|

||

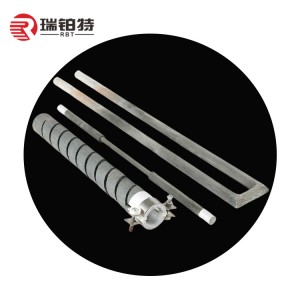

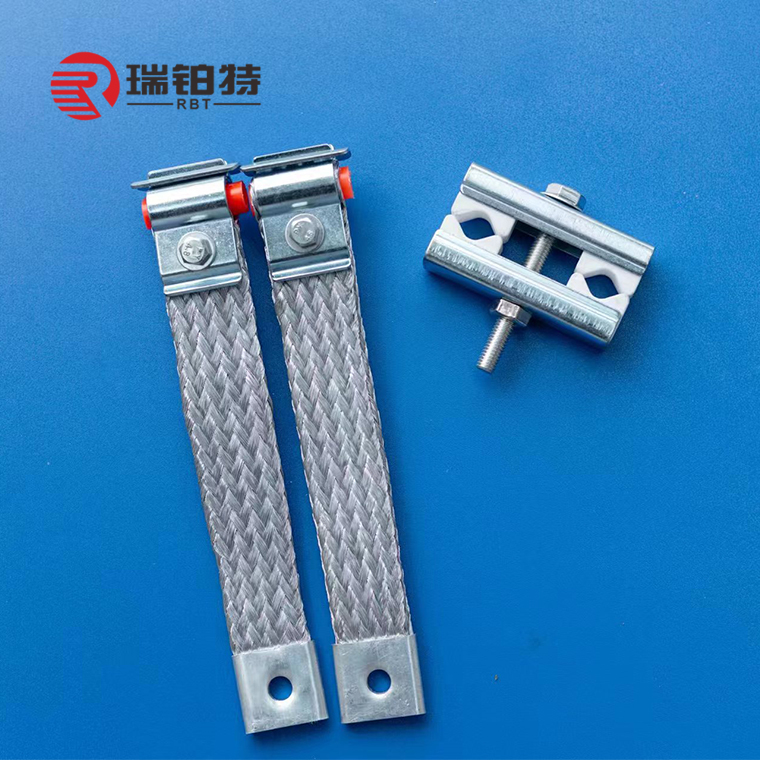

Details Images

Special-shaped

Combination

Combination

Fixture

Combination

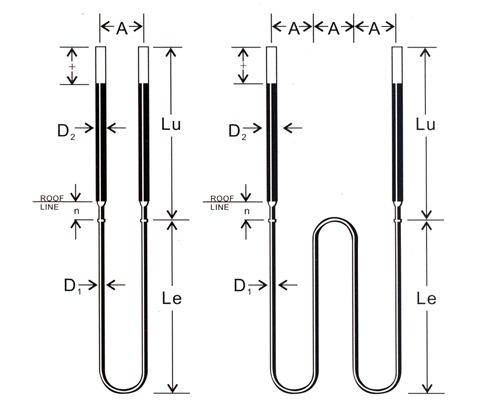

Standard Diameter Size For MoSi2 Muffle Furnace Heating Element

M1700 Type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24 M1800 Type (d/c): dia3/6, dia4/9, dia6/12, dia9/18, dia12/24 (1) Le: Length of Hot Zone (2) Lu: Length of Cold Zone (3) D1: Diameter of Hot Zone (4) D2: Diameter of Cold Zone (5) A: Shank Spacing Please let us know these information when you book an order for the MoSi2 muffle furnace heating element.

The Max Temperature of Element In Different Atmospheres

|

Atmospheres

|

Max Element Temperature

|

|

|

DEERXIN Super MS1700

|

DEERXIN Super MS1800

|

|

|

Air

|

1700℃

|

1800℃

|

|

Nitrogen

|

1600℃

|

1700℃

|

|

Argon, Helium

|

1600℃

|

1700℃

|

|

Hydrogen

|

1100-1450℃

|

1100-1450℃

|

|

N2/H2 95/5%

|

1250-1600℃

|

1250-1600℃

|

|

General Applications

|

Mainly used in industrial heat treatment furnaces, sintering furnaces, casting furnaces, glass melting furnaces, smelting furnaces, etc.

|

Mainly used in experimental furnaces, testing equipment and high-temperature sintering furnaces, etc.

|

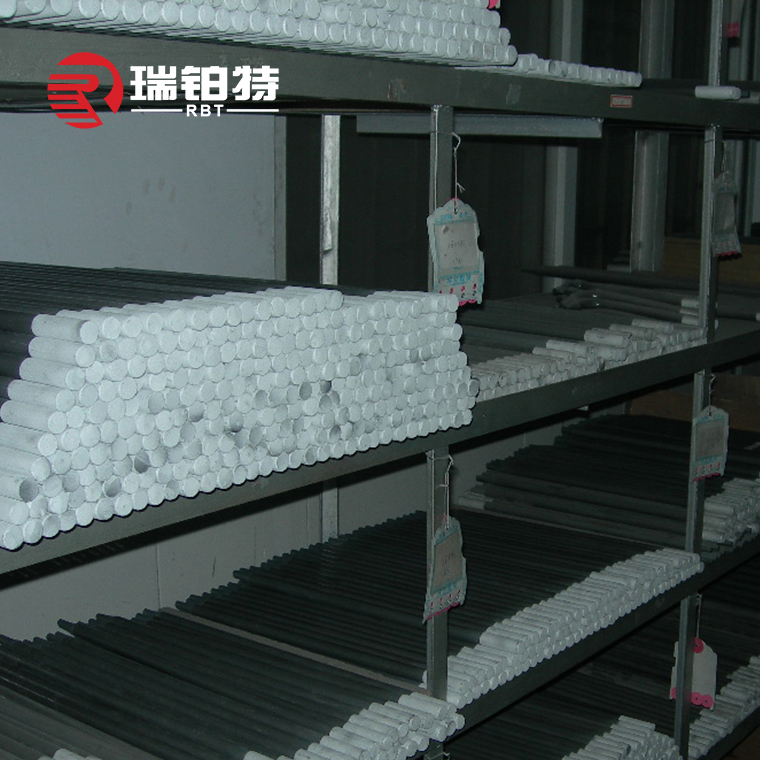

Package&Warehouse

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.