Configuring 5% to 10% (mass fraction) Al2O3 in the matrix part of blast furnace carbon/graphite bricks (carbon blocks) significantly improves the corrosion resistance of molten iron and is the application of aluminum carbon bricks in ironmaking systems. Secondly, aluminum carbon bricks are also used in molten iron pretreatment and tap troughs.

Aluminum carbon bricks for molten iron pretreatment

Aluminum silicon carbide bricks are mainly used in equipment for transporting molten iron such as molten iron tanks. However, when this type of refractory material is used in large molten iron tanks and iron mixers, and encounters harsh heating and cooling conditions, it is prone to cracks, leading to structural peeling. In addition, because the Al2O3-SiC-C bricks used in large hot metal tanks and iron mixers often have a carbon content of 15% and a thermal conductivity as high as 17~21W/(m·K) (800℃), there is a reduction The temperature of molten iron and the problem of deforming the iron sheets of large molten iron tanks and mixing cars. The countermeasure is to achieve low thermal conductivity by removing SiC, a highly thermally conductive component, while reducing the graphite content and refining the graphite.

Through basic research, it is concluded that:

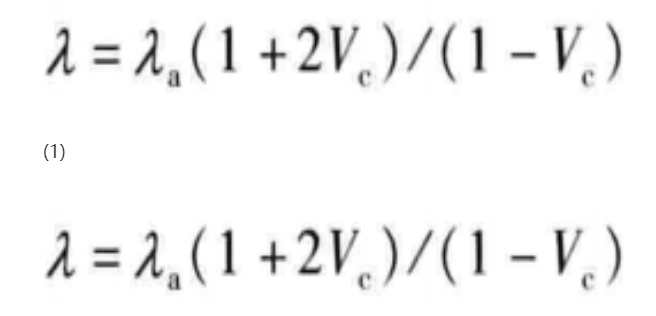

(1) When the graphite content (mass fraction) in aluminum carbon bricks is less than 10%, its organizational structure consists of Al2O3 forming a continuous matrix, and carbon is filled in the matrix in the form of star points. At this time, the thermal conductivity λ of the aluminum carbon brick can be approximately calculated by formula (1)

In the formula, λa is the thermal conductivity of Al2O3; Vc is the volume fraction of graphite. This shows that the thermal conductivity of aluminum carbon bricks has nothing to do with the thermal conductivity of graphite.

(2) When the graphite is refined, the thermal conductivity of the aluminum carbon brick has less dependence on the graphite particles.

(3) For low-carbon aluminum-carbon bricks, when the graphite is refined, a dense bonding matrix can be formed, which can improve the corrosion resistance of the aluminum-carbon bricks.

This shows that low carbon A aluminum carbon bricks can adapt to the operating conditions of large hot metal tanks and iron mixing cars in the ironmaking system.

Post time: Feb-27-2024