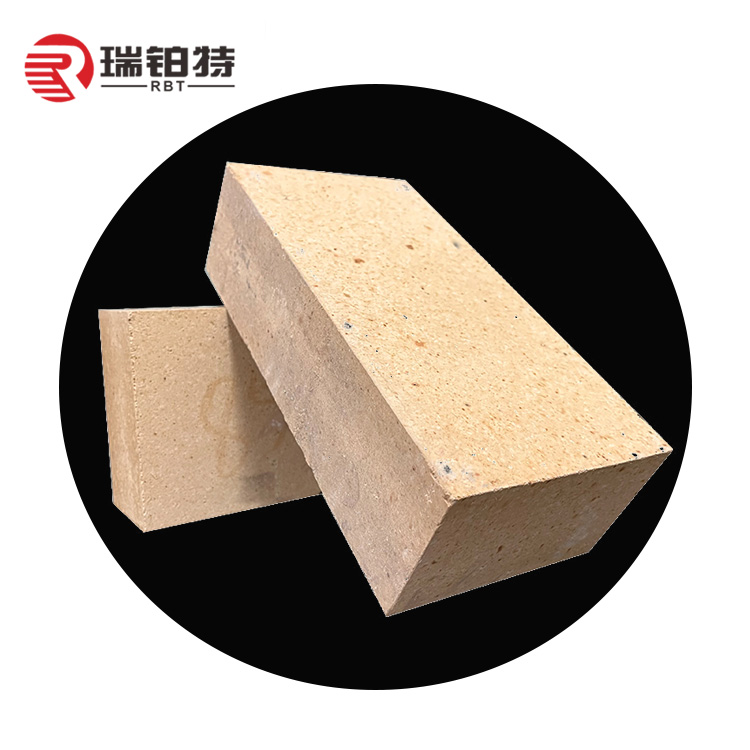

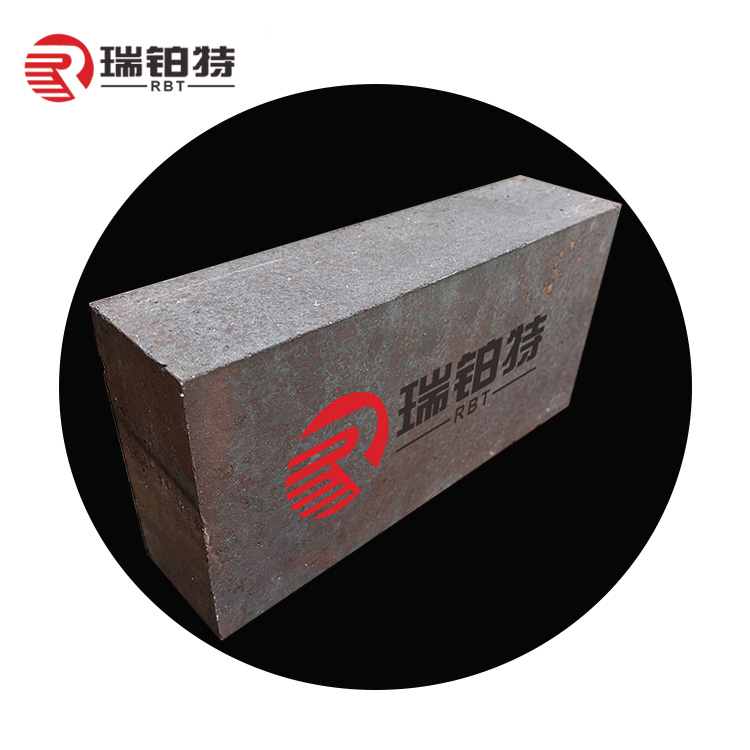

The new type of dry cement rotation kiln is mainly used in the choice of refractory materials, mainly silicon and aluminum refractory materials, high-temperature tie-alkaline refractory materials, irregular refractory materials, prefabricated parts, insulation refractory material products. Among them, it is mainly refractory bricks. Rotal kiln mainly contains high alumina bricks, silicon mullite bricks, magnesium aluminum spinel bricks, magnesium chromium bricks, white cloud stone bricks, and so on. These refractory bricks should pay attention to the following matters and requirements when masonry.

01 The cement ingredients, particle size and cooperative ratio for brick-built bricks must meet the requirements. The cement must be stirred and used in two hours.

02 At the end, the number of bricks must not be less than two lines, and the thickness of the bricks must not be less than 3/4 of the original size. If the gap is 1.5 times the thickness of the design brick, one line should be removed to change the three -line brick. Essence

03 In a brick -building area, the refractory bricks built by each line should be the same level (thickness and tolerance).

04 After the fire -resistant brick is built, the vertical brick seam should be parallel to the central line of the kiln, and the ring brick seam should be perpendicular to the center line of the kiln.

05 The fire -resistant tiles should be flat. The errors of uneven height of the two adjacent bricks shall not exceed 3mm. The brick and the brick must be closely fitted. There must be no gap or loosening.

06 Brick seams are generally used with 2.5mm, 15mm wide, and 2.5mm. The depth of the brick seam must not exceed 20mm. At 10 checkpoints per 5m brick, it should not exceed 3 points more than 3 points exceeding more than 3 points. The brick seams must be inserted and squeezed with thin iron slices for brick seams over 3mm.

07 Precautions for brick built in winter

① The stacking location of the refractory brick must be raised and covered with rainproof cloth to prevent ice and snow from being soaked.

② The working location must have heating and thermal insulation facilities, so that the temperature is not lower than+5 ° C. Even if the work or vacation is stopped, it is not allowed to interrupt the thermal insulation. The refractory cement is stirred with hot water.

Post time: Feb-26-2024