Silicon Carbide Refractory Plate

Product Information

Silicon carbide refractory plate is a kiln lining plate with excellent fire resistance and wear resistance. It is often used in working environments that carry and transfer heat and chemicals under high temperature, high pressure and chemical corrosion conditions. Silicon carbide setter plates are mainly made of silicon carbide and silicon nitride materials, with high bulk density and fire resistance temperature, low thermal conductivity, and are not easy to affect the temperature distribution of the device.

Features:

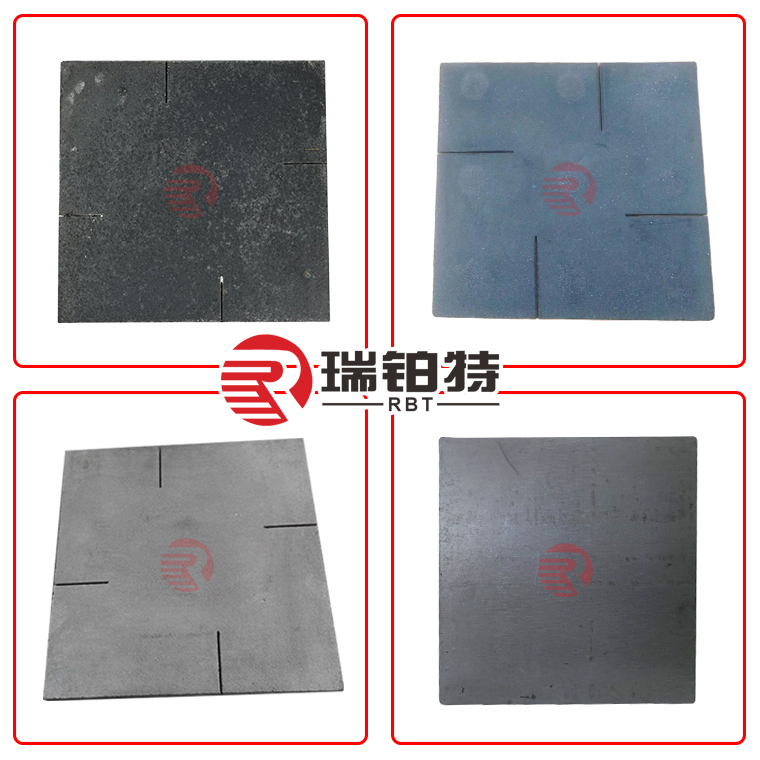

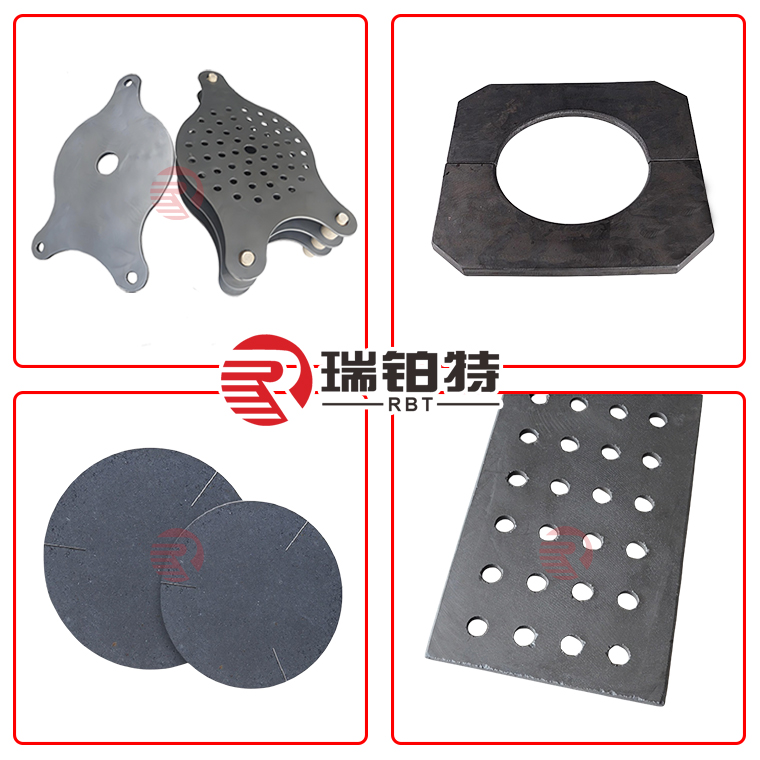

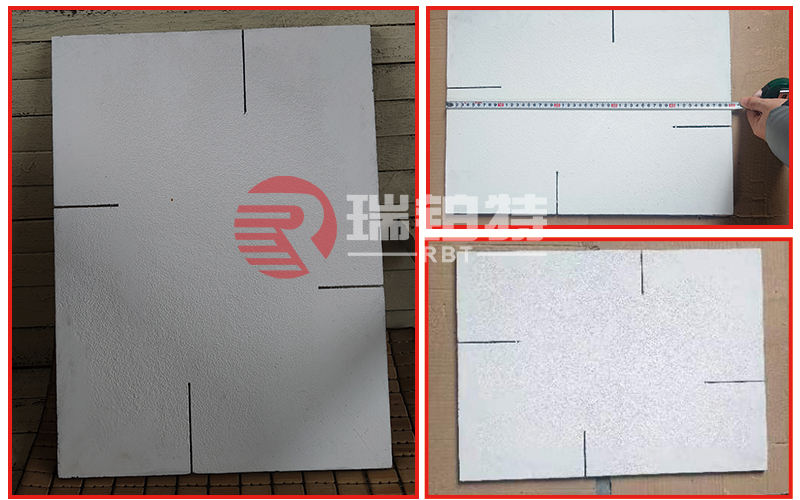

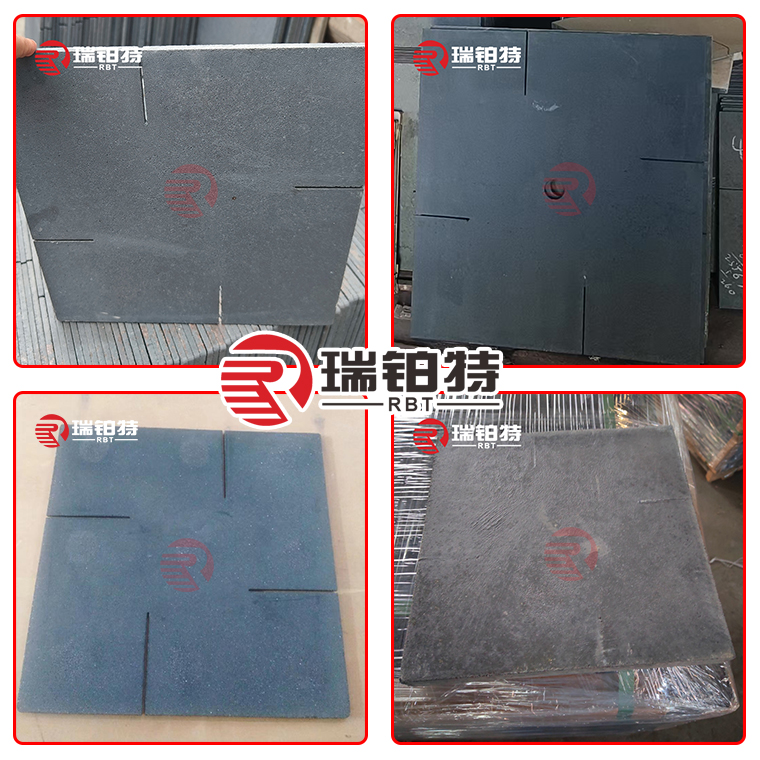

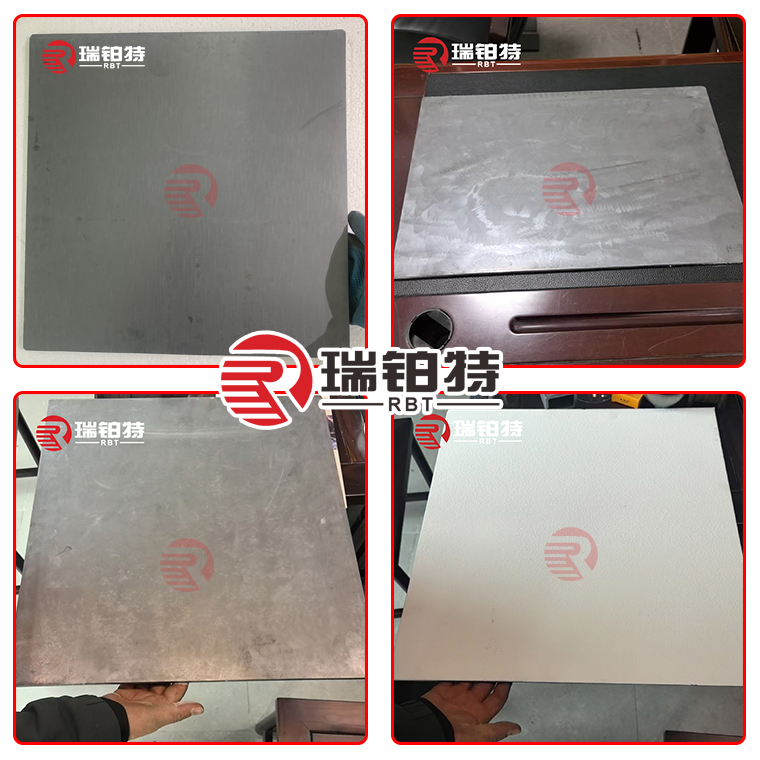

Details Images

Classification By Craft:OSiC/SSiC/RBSiC(SiSiC)/RSiC/NSiC/SiC

Classification By Shape: Square, rectangular, round, semicircular, fish-shaped, porous, special-shaped, etc.

Silicon Carbide Plate with Alumina Coating

Silicon carbide plate with alumina coating can effectively reduce material wear and extend service life by forming a protective layer of alumina on the surface of silicon carbide. At the same time, the acid and alkali resistance of alumina can block the erosion of silicon carbide by external media and improve the corrosion resistance of the material. In addition, alumina has good insulation properties, which can isolate current or heat conduction and avoid the loss of electrical or thermal properties.

Product Index

|

Item

|

SiC

|

RBSiC

|

NSiC

|

RSiC

|

|

|

SiC (%)

|

89

|

87

|

92

|

70

|

99

|

|

Bulk Density (g/cm3)

|

2.85

|

2.8

|

3.01

|

2.8

|

2.75

|

|

Bending Strength (MPa)

|

100

|

90

|

900

|

500

|

300

|

|

Pressure-resisting Strength 1300℃ (MPa)

|

58

|

56

|

280

|

185

|

120

|

|

Operating Temperature (℃)

|

1450

|

1420

|

1300

|

1500

|

1650

|

Common Size Reference

|

Size

|

Weight(kg)

|

Size

|

Weight(kg)

|

Size

|

Weight(kg)

|

|

735x230x16.5

|

7.8

|

590x510x25

|

21

|

500x500x20

|

13.7

|

|

700x600x18

|

21.2

|

590x340x15

|

8.2

|

500x500x15

|

10.5

|

|

700x340x13

|

8.7

|

580x415x14

|

9.2

|

500x500x13

|

9.1

|

|

700x290x13

|

7.4

|

585x375x18

|

11.05

|

500x500x12

|

8.4

|

|

680x580x20

|

22.1

|

580x350x12.8

|

7.3

|

500x480x15

|

10

|

|

660x370x30

|

20.5

|

580x550x20

|

20.5

|

500x480x13

|

8.8

|

|

650x650x25

|

29.5

|

575x450x12

|

8.7

|

500x450x15

|

9.5

|

|

650x220x20

|

8

|

570x570x20

|

18.2

|

500x450x13

|

8.2

|

|

650x320x20

|

11.65

|

570x495x20

|

15.4

|

500x440x15

|

8.8

|

|

650x275x13

|

6.5

|

550x550x13

|

11

|

500x400x20

|

11.2

|

|

640x550x18

|

17.7

|

550x500x15

|

11.5

|

500x400x15

|

8.4

|

|

640x340x13

|

7.9

|

550x500x20

|

15.4

|

500x400x13

|

7.3

|

|

620x420x15

|

10.6

|

550x480x14.5

|

10.65

|

500x400x12

|

6.7

|

|

615x325x20

|

10.7

|

550x450x14

|

9.7

|

500x370x20

|

10.3

|

|

610x450x20

|

15.4

|

550x450x20

|

13.8

|

500x370x15

|

7.8

|

|

600x580x20

|

19.4

|

550x400x13

|

8.1

|

500x370x13

|

6.6

|

|

600x550x15

|

13.8

|

550x370x12

|

6.6

|

500x370x12

|

6.2

|

|

600x500x15

|

12.6

|

540x410x15

|

9.1

|

500x300x13

|

5.5

|

|

600x500x20

|

16.8

|

530x340x13

|

6.6

|

500x230x17

|

5.5

|

|

600x480x15

|

12

|

540x330x13

|

6.5

|

480x460x14

|

8.4

|

|

600x400x13

|

8.7

|

540x240x10

|

3.6

|

480x450x13

|

7.6

|

|

600x400x15

|

10

|

530x540x20

|

15.8

|

480x380x12

|

6.15

|

|

600x400x20

|

13.4

|

530x330x12.5

|

6

|

480x370x12

|

5.95

|

|

600x370x15

|

9.3

|

525x390x14

|

8

|

480x360x12

|

5.8

|

|

600x355x15

|

8.9

|

525x390x12.5

|

7.1

|

480x340x12

|

5.5

|

|

600x300x13

|

6.6

|

520x500x20

|

14.5

|

480x330x12

|

5.3

|

|

520x480x15

|

10.5

|

520x500x15

|

10.9

|

480x300x12

|

4.8

|

|

520x420x15

|

9.1

|

520x500x13

|

9.45

|

480x310x12

|

5

|

|

520x200x13

|

4.2

|

520x480x18

|

12.5

|

480x230x17

|

5.3

|

|

460x440x13

|

7.2

|

460x355x18

|

10.5

|

480x200x15

|

4

|

Application

High-end sanitary ware: Silicon carbide refractory plate plays an important role in the firing process of high-end sanitary ware. Its excellent chemical corrosion resistance and high temperature resistance make the fired sanitary ware have higher quality and durability.

Daily ceramics: In the firing of daily ceramics, silicon carbide setter plate can provide a stable sintering environment to ensure the quality and appearance of ceramic products. Its high temperature strength and thermal shock stability make daily ceramics more solid and beautiful.

Craft ceramics: In the firing process of craft ceramics, the application of silicon carbide setter plate can improve the precision and surface smoothness of the product. Its excellent refractory performance and high temperature stability ensure the high-quality production of craft ceramics.

Kiln furniture: Silicon carbide setter plate is also widely used in kiln furniture. Its excellent high temperature bearing capacity and thermal conductivity make the kiln furniture remain stable in high temperature environment, extending the service life of the kiln furniture.

Other industrial applications: Silicon carbide refractory plate is also used in other industrial fields, such as power electronics, photovoltaic power generation, etc. Its high strength, high hardness and high temperature resistance make it stable and durable even in harsh working environments.

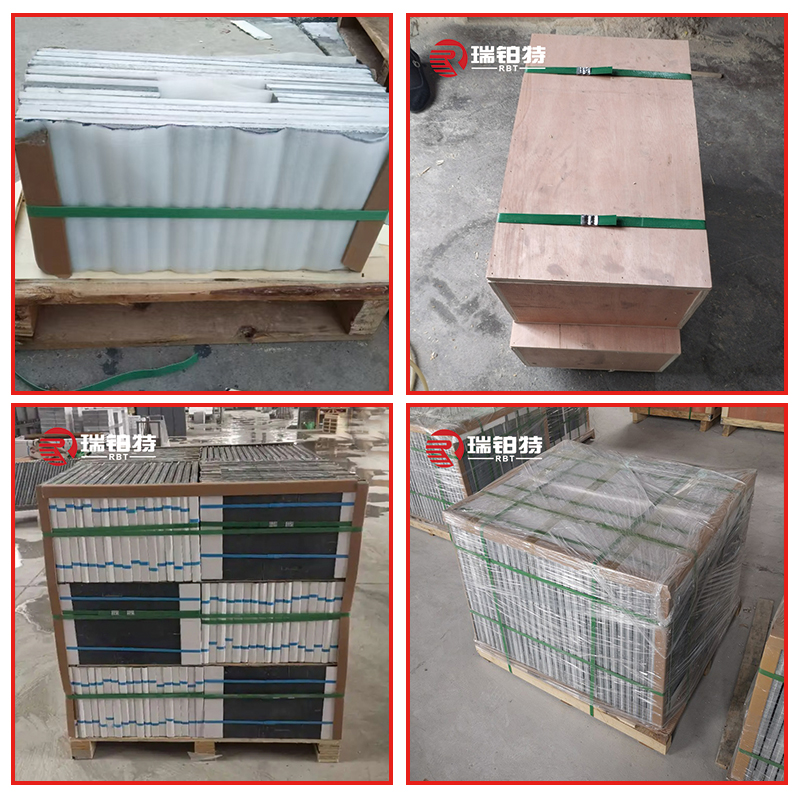

Package&Warehouse

Company Profile

Shandong Robert New Material Co., Ltd. is located in Zibo City, Shandong Province, China, which is a refractory material production base. We are a modern enterprise that integrates the research and development, production, sales, kiln design and construction, technology, and export refractory materials. We have complete equipment, advanced technology, strong technical strength, excellent product quality, and good reputation. Our factory covers over 200 acres and an annual output of shaped refractory materials is approximately 30000 tons and unshaped refractory materials is 12000 tons.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.