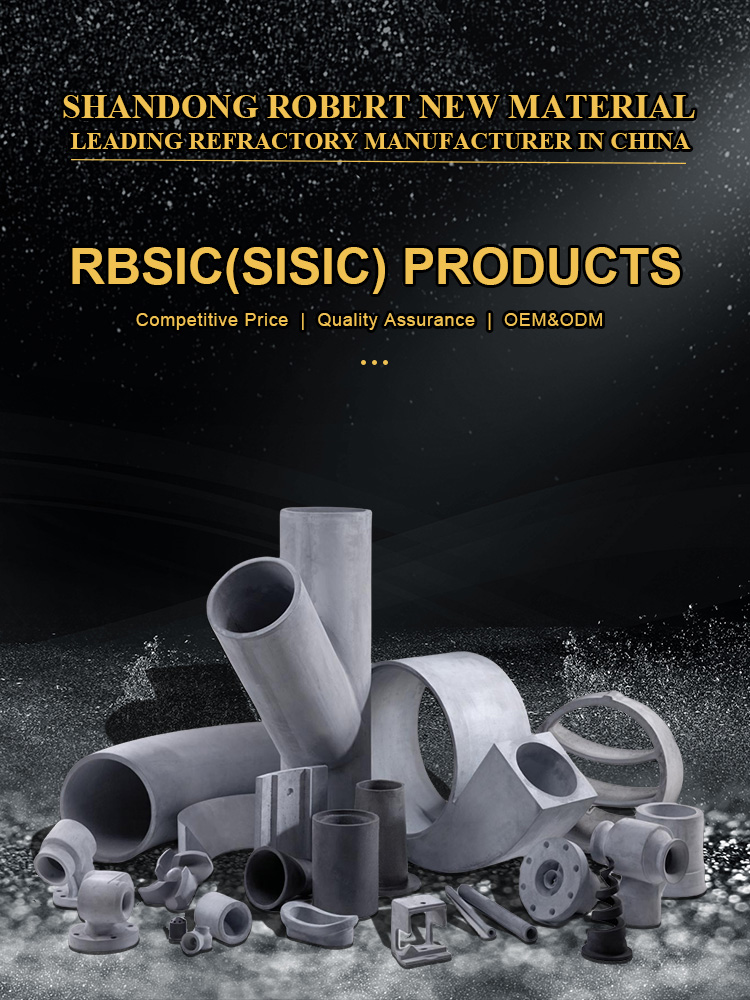

RBSiC(SiSiC) Products

Product Information

|

Product Name

|

RBSIC(SiSiC) Products(Reactive Sintering Silicon Carbide Products)

|

|

Description

|

Siliconized SiC is a silicon reaction that is uniformly mixed and infiltrated with fine particles of SiC, carbon powder and additives in proportion to generate SiC and combine with SiC, excess silicon fills the gaps to obtain highly dense ceramic materials.

|

|

Feature

|

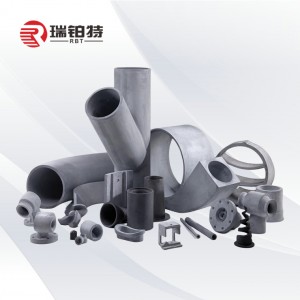

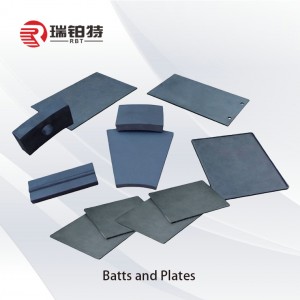

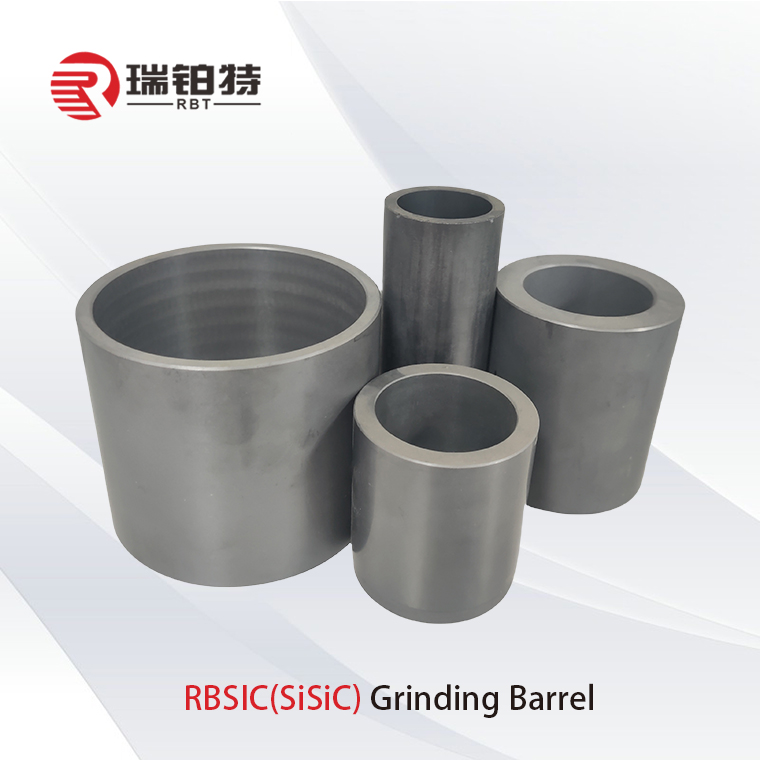

The material of siliconized silicon carbide has series of basic superiority and characteristic such as high strength, extreme hardness, wear resistance, high temperature tolerance, corrosion resistance, oxidation resistance thermal shock resistance, high thermal conductivity, low coefficient of thermal expansion, creep resistance under high temperature and so on. Many products can be made from it such as beams, rollers, cooling air pipes, thermal couple protection tubes, temperature-measuring tubes, sealing parts, and special shaped parts. |

Product Index

|

Item

|

Unit

|

Data

|

|

Max Temperature of Application

|

℃

|

≤1380

|

|

Density

|

g/cm3

|

>3.02

|

|

Open Porosity

|

%

|

≤0.1

|

|

Bending Strength

|

Mpa

|

250(20℃); 280(1200℃)

|

|

Modulus of Elastictiy

|

Gpa

|

330(20℃); 300(1200℃)

|

|

Thermal Conductivity

|

W/m.k

|

45(1200℃)

|

|

Thermal Expansion Coefficient

|

K-1*10-6

|

4.5

|

|

Moh's Hardness

|

|

9.15

|

|

Acid Alkaline-Proof

|

|

Excellent

|

Details Images

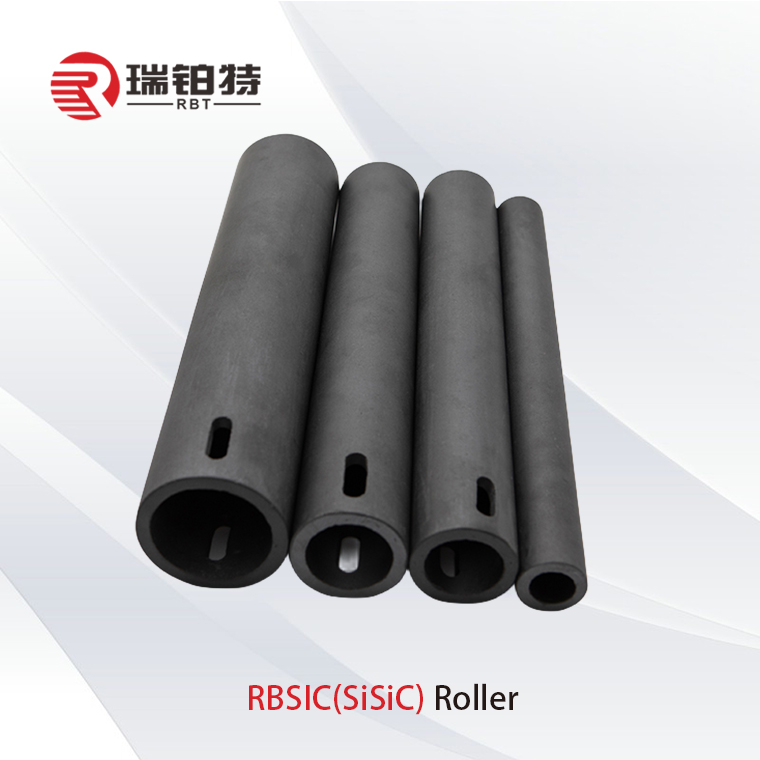

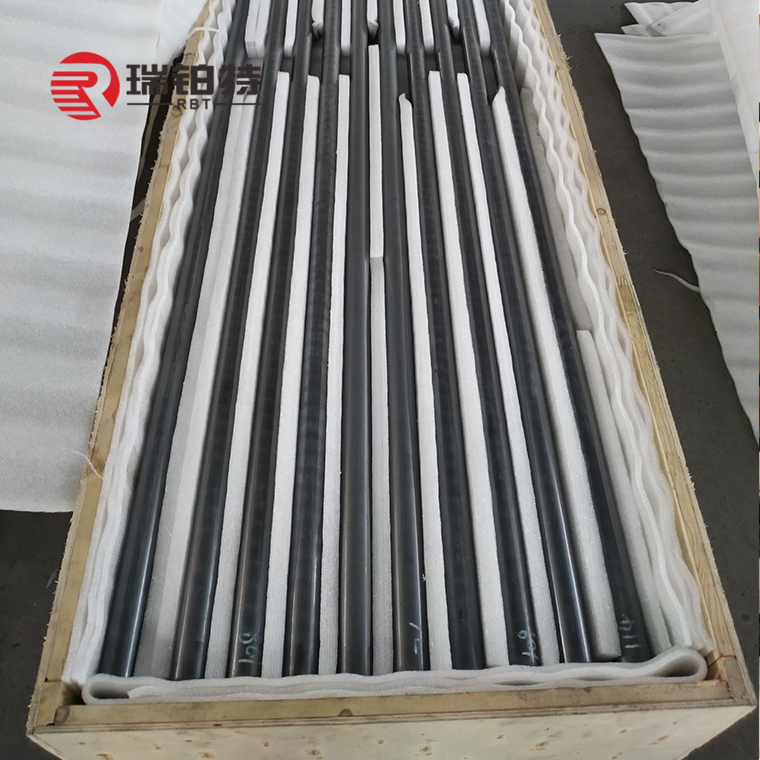

Feature: The excellent chemical corrosion resistance of silicon carbide roll rod makes it can work for a long time in the strong corrosive atmosphere environment of lithium electric kiln, and has a longer life.

|

Bearing Capacity of RBSic(SiSiC) Rollers

|

|||

|

Size of Section(mm)

|

Wall Thickness(mm)

|

Concentrated Loading(kg.m/L)

|

Uniformly Distributed Loading(kg.m/L)

|

|

30

|

5

|

43

|

86

|

|

35

|

5

|

63

|

126

|

|

35

|

6

|

70

|

140

|

|

38

|

5

|

77

|

154

|

|

40

|

6

|

97

|

197

|

|

45

|

6

|

130

|

260

|

|

50

|

6

|

167

|

334

|

|

60

|

7

|

283

|

566

|

|

70

|

7

|

405

|

810

|

Application: Swimming kiln, tunnel kiln, roller kiln, and other industrial kiln bearing structure and the kiln truck bearing products.

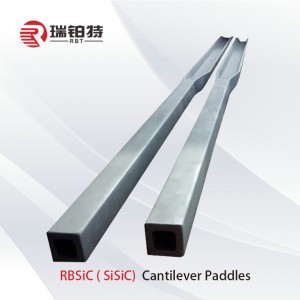

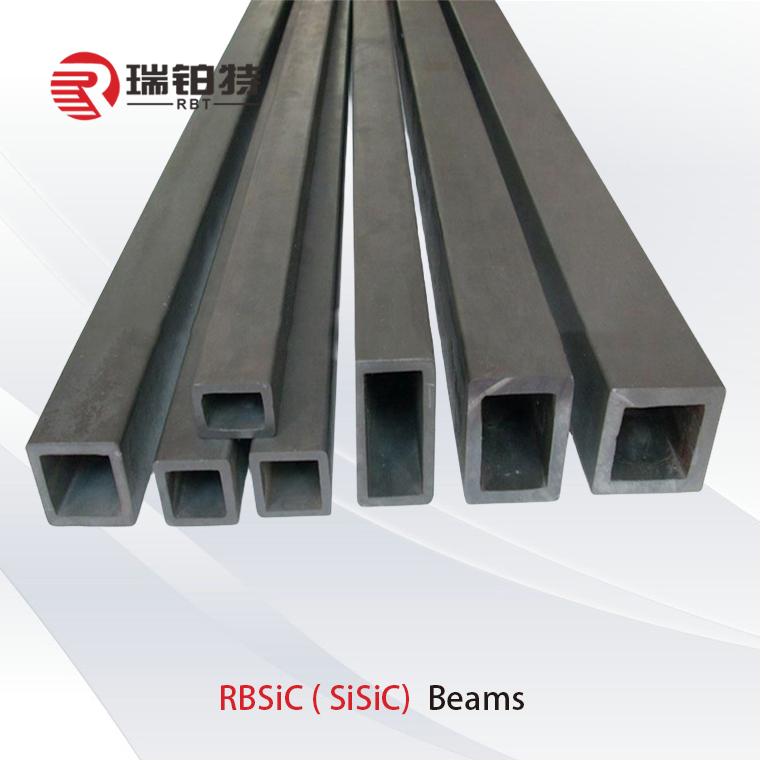

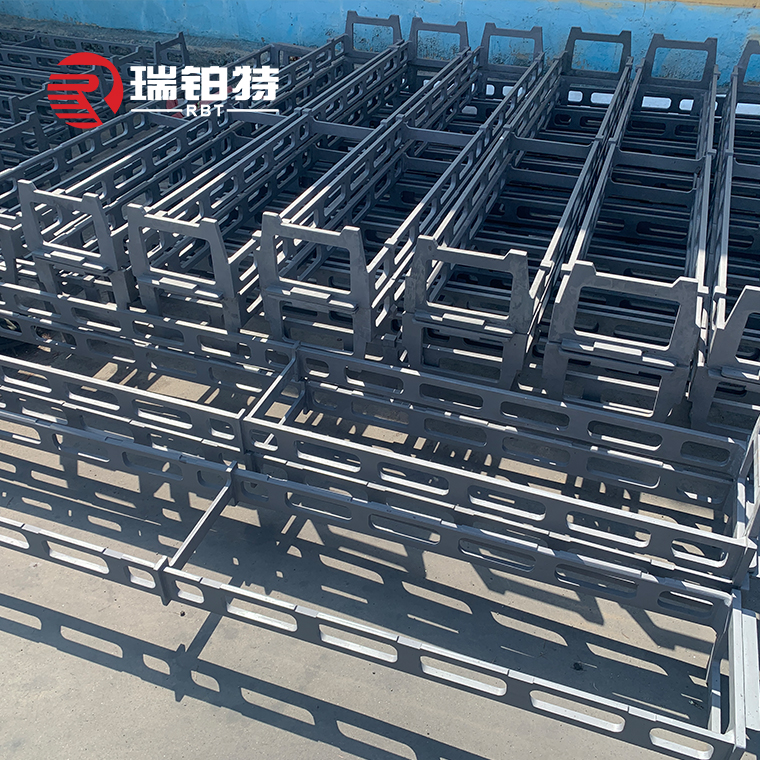

Feature: Silicon carbide square beam has the advantages of large high temperature bearing capacity, good thermal conductivity, high temperature creep resistance and energy saving. lt is the ideal kiln for lithium electric roller rod kiln, electronic ceramic powder, sanitary ware, daily ceramics, electric porcelain, refractory materials, foam ceramics, and other industries.

|

Bearing Capacity of RBSic(SiSiC) Beams

|

||||||

|

Size of Section

(mm)

|

Wall

Thickness

(mm)

|

Concentrated Loading(kg.m/L)

|

Uniformly Distributed Loading(kg.m/L)

|

|||

|

B Side

|

H Side

|

W Side

|

H Side

|

W Side

|

H Side

|

|

|

30

|

30

|

5

|

74

|

74

|

147

|

147

|

|

30

|

40

|

5

|

117

|

95

|

235

|

190

|

|

40

|

40

|

6

|

149

|

149

|

298

|

298

|

|

50

|

50

|

6

|

283

|

283

|

567

|

567

|

|

50

|

60

|

6

|

374

|

331

|

748

|

662

|

|

50

|

70

|

6

|

473

|

379

|

946

|

757

|

|

60

|

60

|

7

|

481

|

481

|

962

|

962

|

|

80

|

80

|

7

|

935

|

935

|

1869

|

1869

|

|

100

|

100

|

8

|

1708

|

1708

|

3416

|

3416

|

|

110

|

110

|

10

|

2498

|

2498

|

4997

|

4997

|

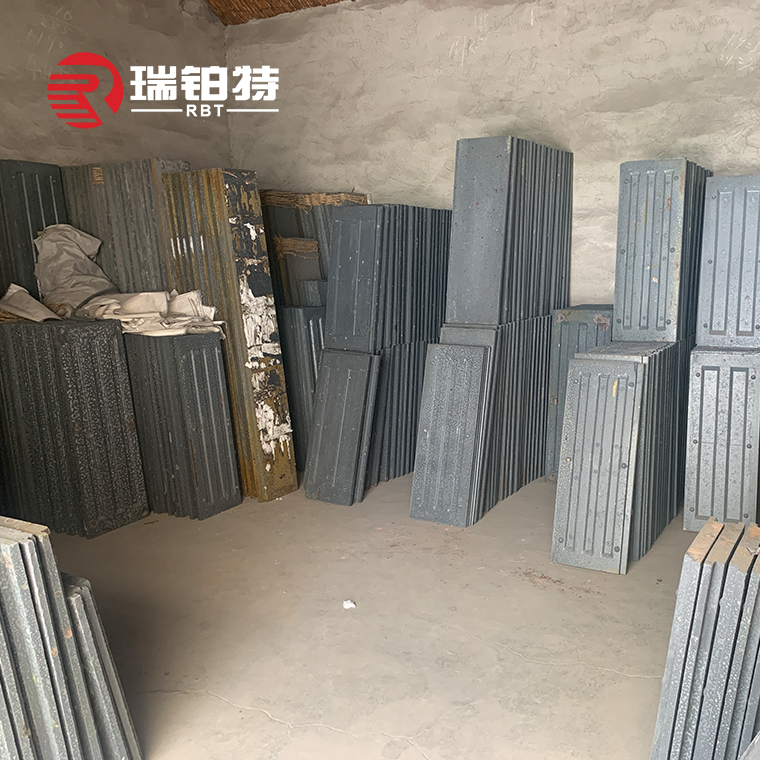

Burner Casing

Radiation Tube

Liners

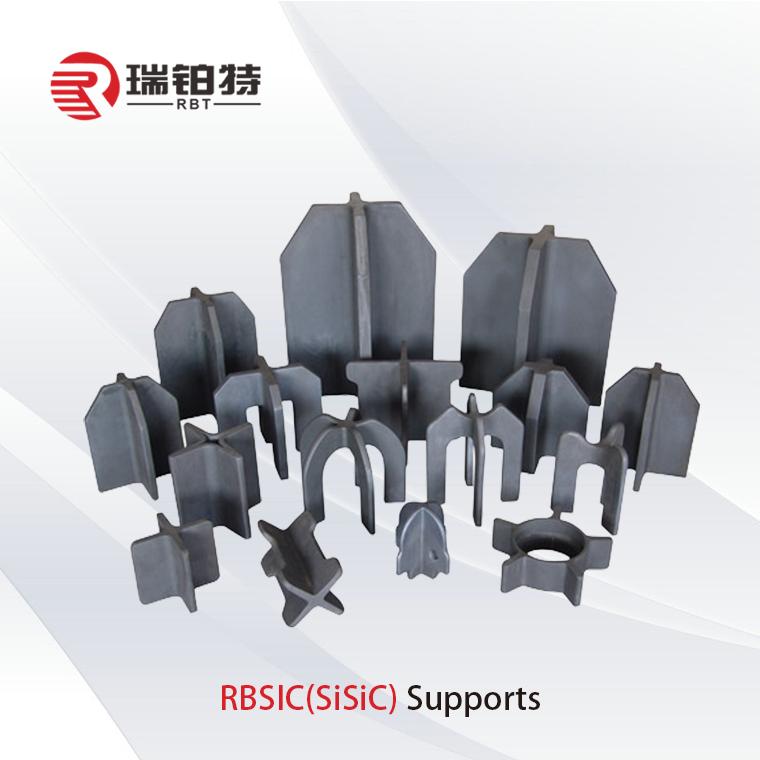

Supports

Package&Warehouse

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

We are a real manufacturer, our factory is specialized in producing refractory materials for more than 30 years. We promise to provide the best price, the best pre-sale and after-sale service.

For each production process, RBT has a complete QC system for chemical composition and physical properties. And we will test the goods, and the quality certificate will be shipped with the goods. If you have special requirements, we will try our best to accommodate them.

Depending on the quantity, our delivery time is different. But we promise to ship as soon as possible with guaranteed quality.

Of course, we provide free samples.

Yes, of course, you are welcome to visit RBT company and our products.

There is no limit, we can provide the best suggestion and solution according to your situation.

We have been making refractory materials for more than 30 years, we have strong technical support and rich experience, we can help customers design different kilns and provide one-stop service.